BMW’s investment arm – i Ventures – continues to expand their portfolio of companies with a new partnership. This week, BMW Group acquired a stake in Bcomp, a Swiss company that manufactures sustainable reinforcement solutions. At the same time, the two companies are also strengthening their partnership on the motorsport side, with Bcomp now an official BMW M Motorsport partner with the new BMW M4 GT4 racing car.The collaboration will also kick off the development of renewable raw materials for components in future vehicle models.

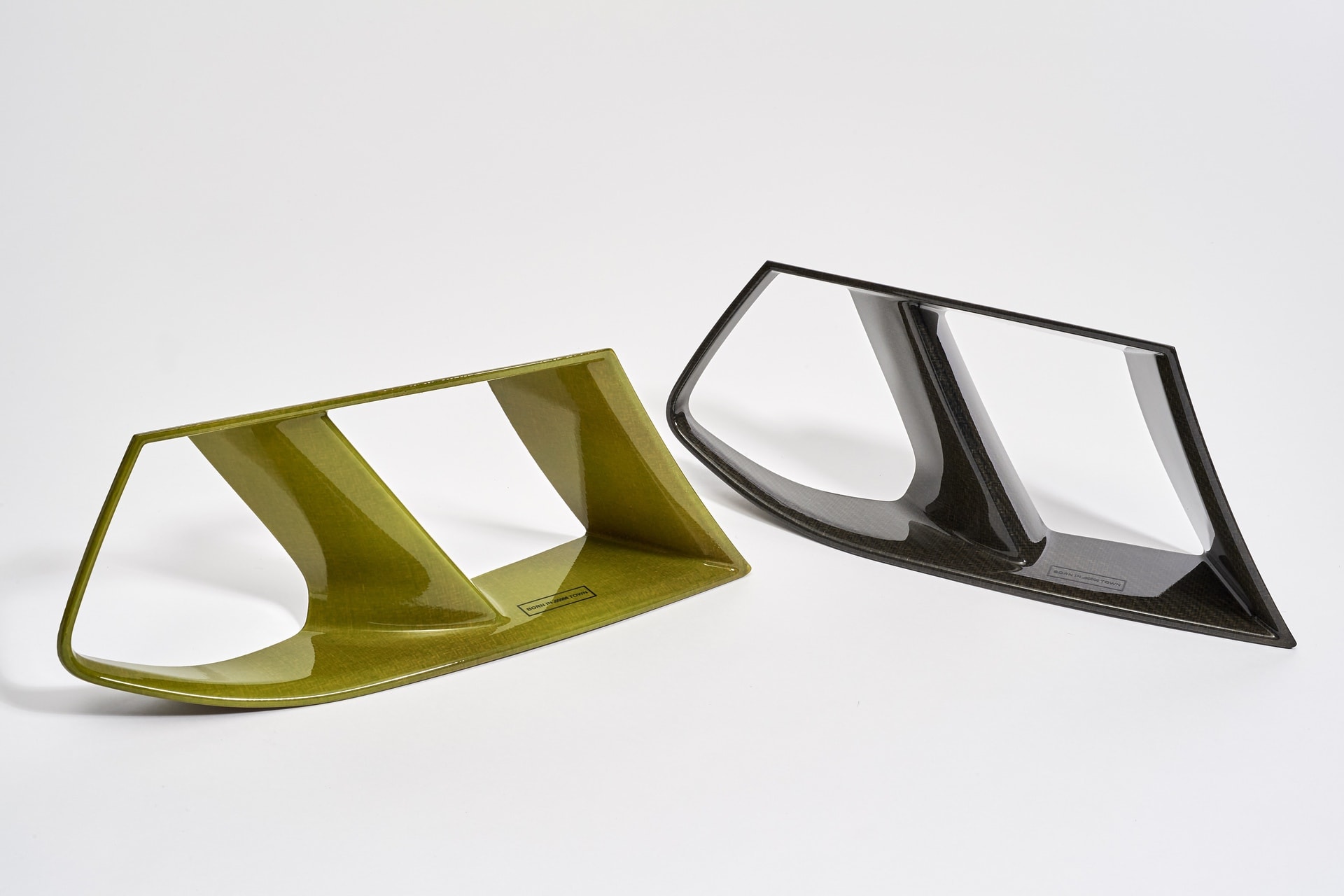

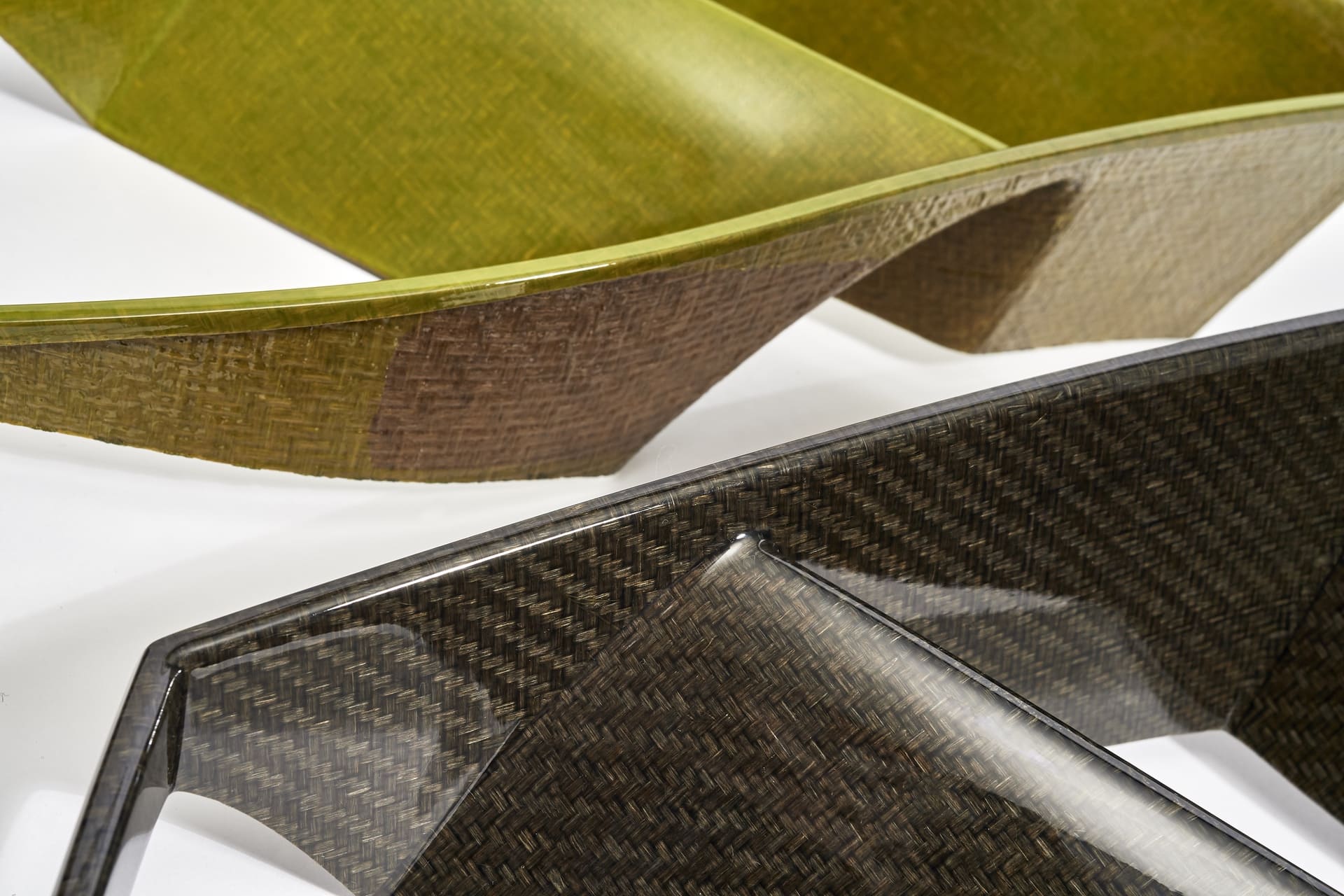

Bcomp’s involvement with BMW started in 2019 when its reinforcement solutions were used by BMW Motorsport in Formula E cars. The flax cooling shaft on the BMW iFE.20 made it the first BMW racing car with parts constructed from renewable plant fibres. Meanwhile, the Bcomp-developed powerRibs™ and ampliTex™ reinforcement solutions made from natural composite materials have been used in DTM touring cars from BMW M Motorsport to substitute selected carbon fiber-reinforced plastic (CFRP) components.

As BMW is known for transferring tech from the track to the road, these new material technologies will also find their way into BMW M models and BMW M Performance Parts. “Product sustainability is increasing in importance in the world of motorsport too,” says Franciscus van Meel, Chairman of the Board of Management at BMW M GmbH. “So we are delighted to have Bcomp on board as an official BMW M Motorsport partner for the BMW M4 GT4 project.”

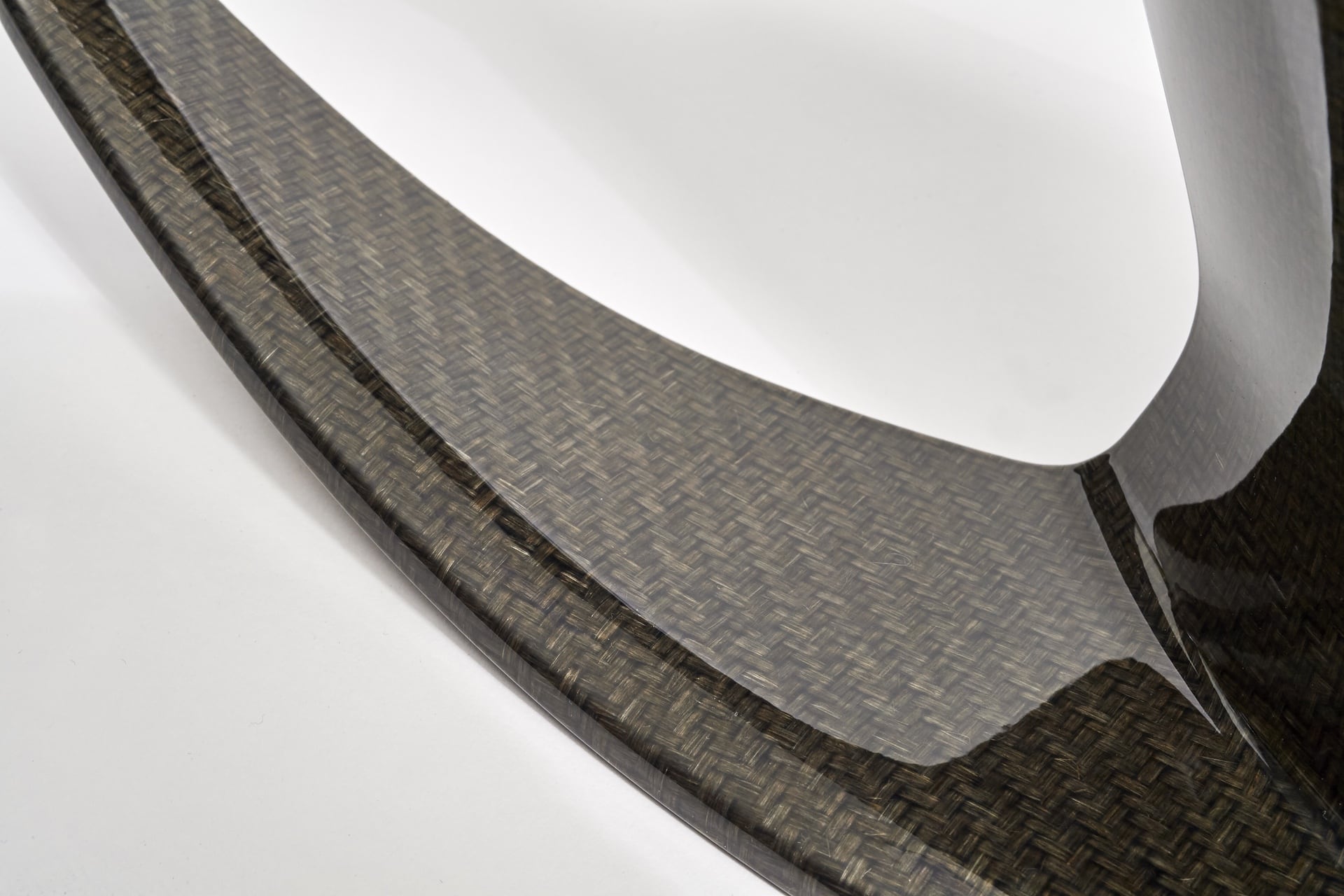

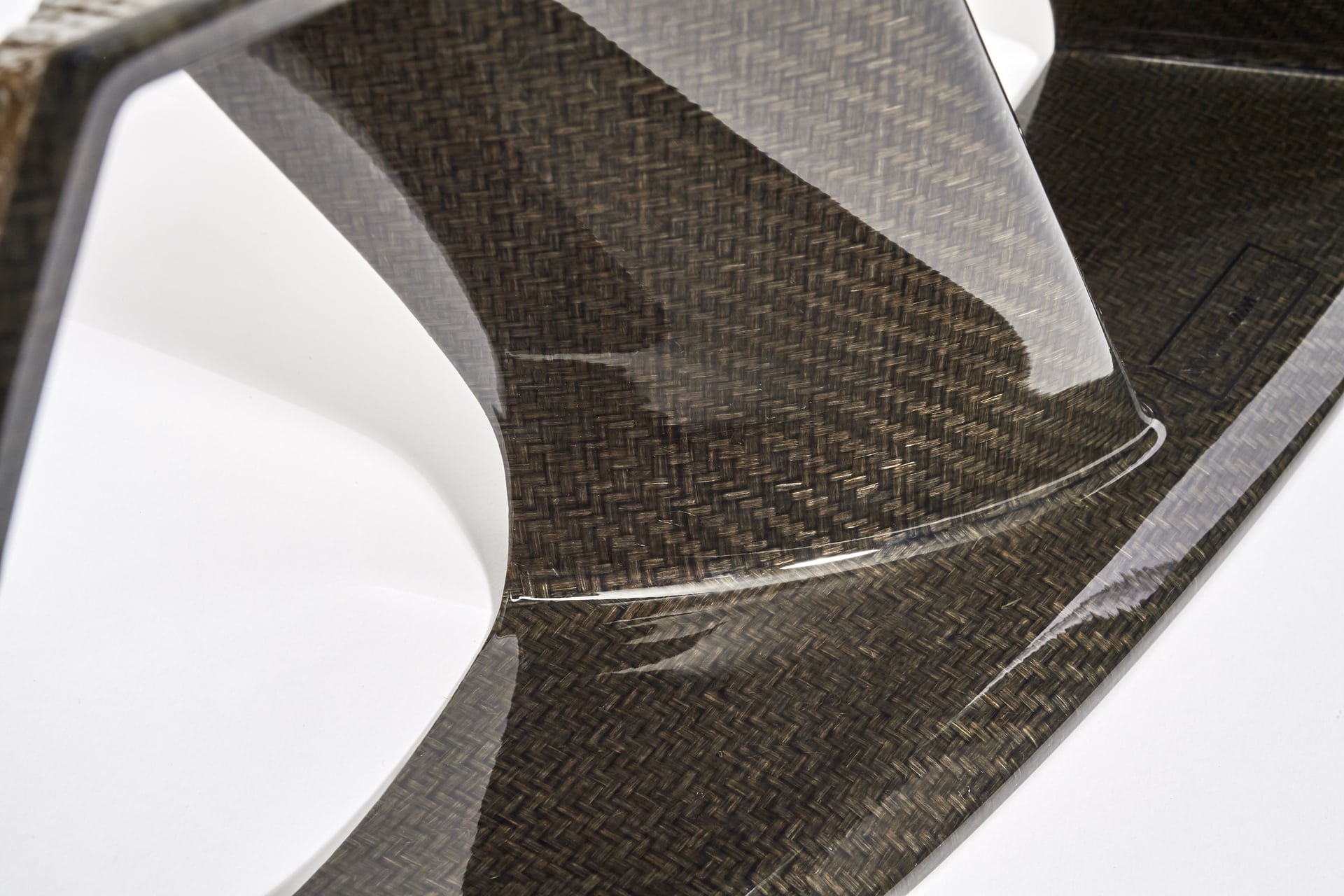

Inspired by leaf veins, the powerRibs™ reinforcement technology developed by Bcomp maximizes stiffness with minimal weight by creating a 3D structure on one side of a thin-walled shell element. This enables a decrease in the amount of base material used, thereby reducing weight, costs and consumables in production. The ampliTex™ reinforcements add a visible layer of flax fibres as a carbon-neutral replacement for the conventional covering material.

Combining the two materials makes it possible to cut the amount of plastic used for interior panelling by up to 70 per cent and at the same time to lower CO2 emissions by as much as 60 per cent. The result is more sustainable vehicle components, whose failure mode has the additional benefit of increasing safety over traditional composites. The natural-fibre composites also lend themselves to use with classical motor sport accessories, such as those in the BMW M Performance Parts range.

BMW is seeking to lower its vehicles’ lifecycle carbon emissions by over 40 per cent by 2030 compared to 2019 levels. So it comes as no surprise that BMW has been investing in research and development in the field of renewable materials over the years.