While some might be accusing BMW of stalling on the development of electric and electrified vehicles, the German company keeps marching on. Today they announced a new contract was signed with battery supplier, Northvolt, for an order worth 2 billion euros. The details of the contract make it noteworthy though and separate BMW from other manufacturers.

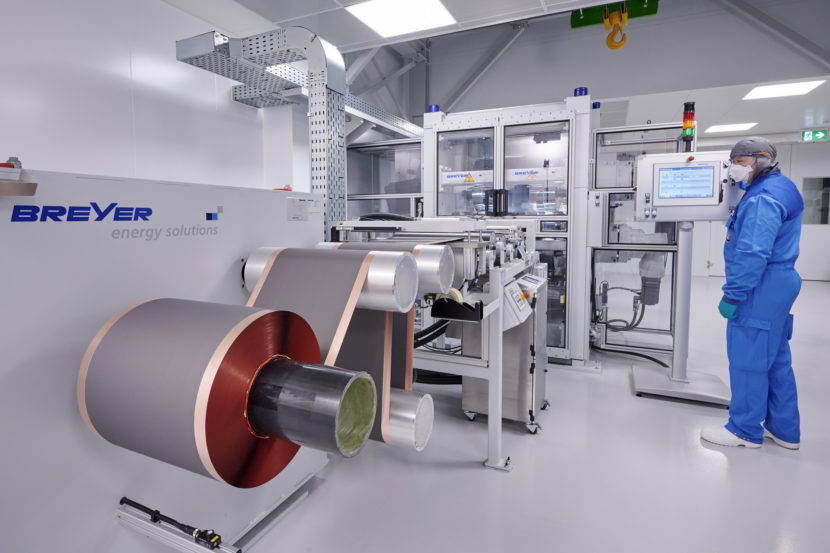

The Bavarian company has always emphasized on the impact batteries have on the environment. Thus, for the i brand, for example, the entire production process was optimized to cut CO2 emissions as much as possible, among other things. The same guidelines were kept for this contract as well. The battery cells will be produced in Europe, at the Northvolt gigafactory currently under construction in Skellefteå in northern Sweden.

The most important aspect about this order though was the demand that Northvolt will obtain 100 percent of the energy needed to produce the battery cells regionally in northern Sweden and exclusively from wind and hydroelectric power. “To make an effective contribution to climate protection, we aim to improve our products’ overall environmental balance – from resources to recycling. This applies in particular to energy-intensive production of high-voltage batteries for electric vehicles. That is why we now have a contractual agreement with our cell manufacturers that they will only use green power to produce our fifth-generation battery cells,” said Oliver Zipse, Chairman of the Board of Management of BMW AG.

BMW and Northvolt will commonly source the cobalt and lithium needed as key raw materials for cell production from mines that fulfill the high sustainability standards of both companies. This ensures full transparency of the origin of raw materials at any time. Compliance with environmental standards, respect for human rights and reducing the carbon footprint are top priority. BMW will also no longer use rare earths in its fifth-generation electric drive trains from 2021 on.

The BMW Group and Northvolt are pursuing their goal of a sustainable value chain for battery cells in Europe through a joint technology consortium. Recyclable cell design is a consistent focus throughout the development of battery cells. Faced with rapidly growing demand for battery cells, recycling of battery components at the end of their life cycle and extensive reuse of raw materials will be key to closing the materials loop in the best way possible.