BMW’s first-ever inline-six-cylinder engine, designated as the M78, was produced from 1933 to 1950. The initial version, the 303, featured a 5.6:1 compression ratio, a 56mm cylinder bore, and an 80mm stroke, resulting in approximately 29 horsepower and 68 Nm of torque. Though it may not sound like much in today’s world, it marked the beginning of a new era for BMW.

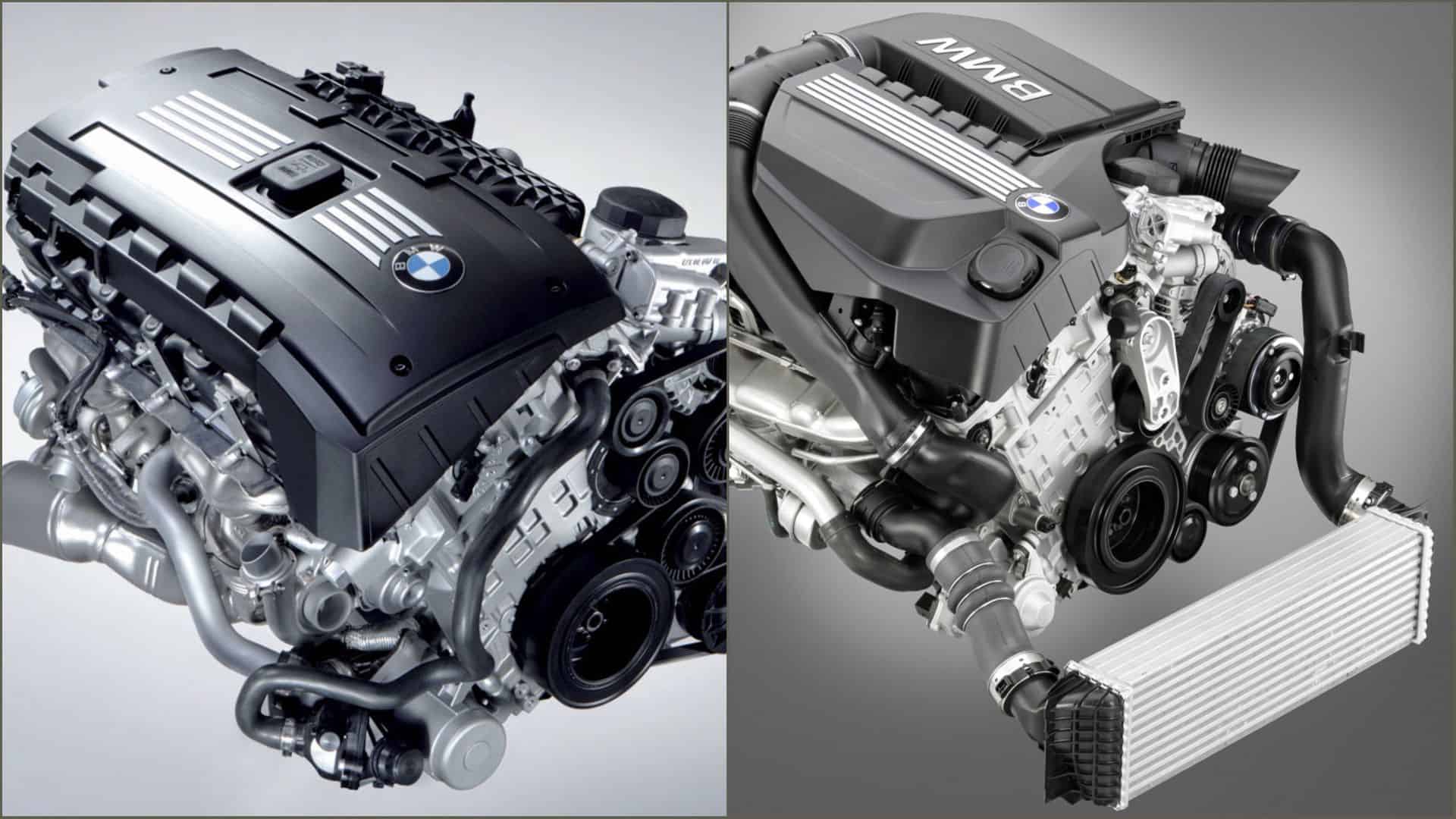

The N54 Engine: BMW’s First Mass-Produced Turbocharged Gasoline Engine

In 2006, BMW released the N54 engine, the successor to the naturally aspirated inline-six-cylinder N52 engine, and boy, did it live up to its hype. The N54B30O0 became BMW’s first mass-produced turbocharged gasoline engine in over 30 years. A fun fact: BMW unveiled their first-ever turbocharged vehicle, the 2002 turbo fitted with the M10 engine, back in 1973, igniting the turbocharger craze that continues today.

The N55 Engine: The N54’s Successor

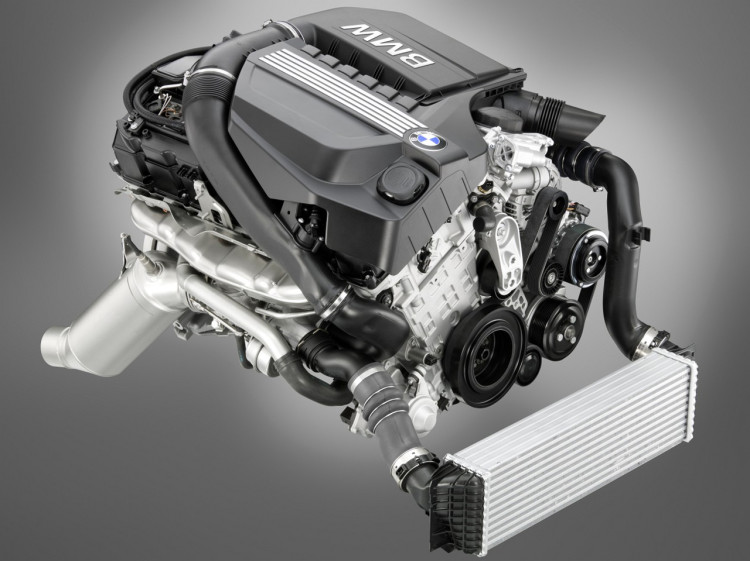

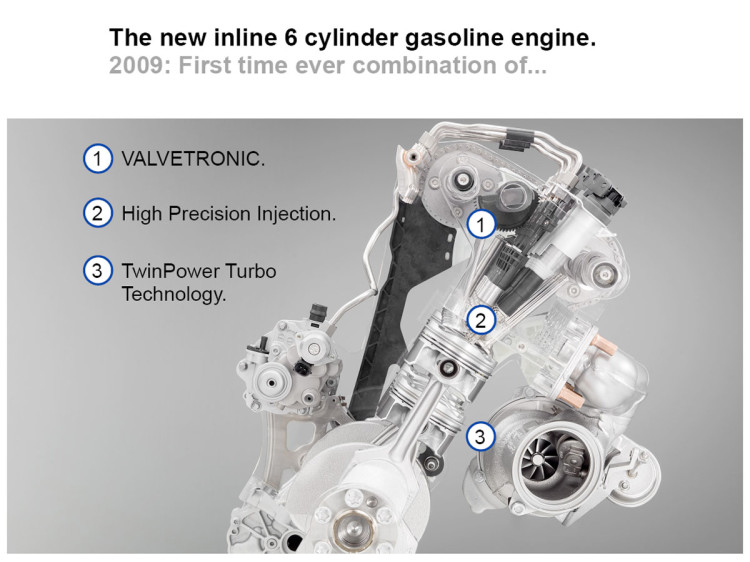

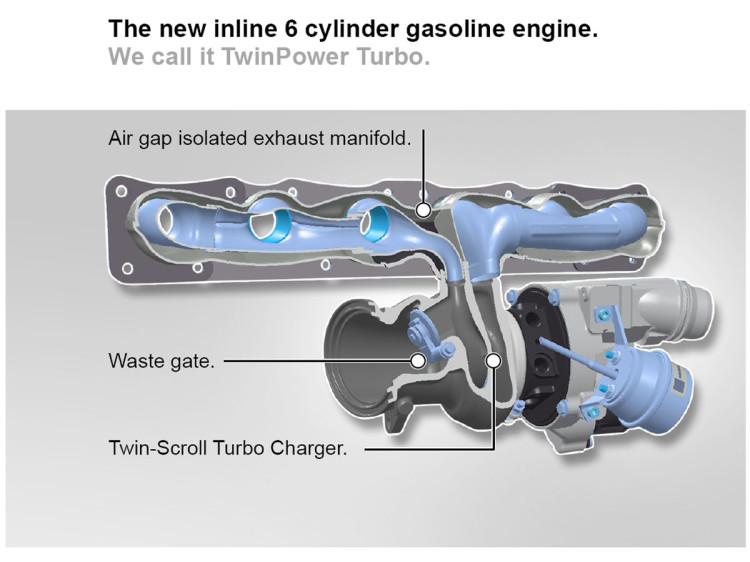

In 2009, BMW revealed the N55 engine, succeeding the N54 and internally designated as N55B30M0. The main difference between the N54 and N55 engines was the use of two exhaust turbochargers (bi-turbo technology) on the N54 and a single twin-scroll exhaust turbocharger on the N55. The N54 also utilized a vacuum-controlled blow-off valve and wastegate, while the N55 used an electric blow-off valve with a vacuum-controlled wastegate until June 2013 when it was switched to an electronically controlled wastegate. These engines share many similarities, with reduced costs and improved quality being the main distinguishing factors.

The Differences Between the N54 and N55 Engines

The N54B30O0 and N55B30M0 possess virtually the same technical data: approximately 300 horsepower, 400 Nm of torque, 1-5-3-6-2-4 firing order, direct charge air cooler, 3-piston high-pressure fuel pump capable of reaching system pressures of up to 200 bar/2,900 psi, Double-VANOS, electric coolant pump, aluminum crankcase, 10.2:1 compression ratio, 89.6mm stroke/84mm cylinder bores, 24-valve inline six-cylinder, 2-stage vacuum pump, 82.5mm full slipper skirt pistons, and an open-deck engine block design, to name a few. The tuning potential of these engines is insane, by the way; with full bolt-ons, they are proven to produce well over 800+ horsepower – sign me up.

The Tuning Potential of the N54 and N55 Engines

The differences between the N54 and N55 are just as interesting as their similarities and their potential for a massive power increase. The N54 used a fuel injection system known as BMW HPI or High Precision Injection with Piezoelectric Fuel Injectors. BMW switched to a newer fuel injection system with the N55 called BMW HDE or High-Pressure Fuel Injection with Bosch Solenoid Valve Fuel Injectors with CVO support. Unbeknownst to many, the N54 did not have BMW’s coveted Valvetronic. This was released for the first time in a turbocharged BMW engine on the N55 and utilized BMW’s Valvetronic III system with a small, yet very powerful, brushless DC servomotor.

The Performance of the N54 and N55 Engines

The N54 was used in vehicles such as the 135i (E82/E88), 335i (E90/E92/E93), Z4 sDrive35is (E89), and even the X6 xDrive35i (E71), to name a few. The BMW 1M Coupe received a modified version of the same engine, designated N54B30T0, which produced approximately 340 horsepower and 450 Nm of torque with an additional 50+ Nm overboost function. Pretty nice figures for a vehicle that weighs 3,200 lbs. The 1M’s also hold their value extremely well and are super rare – check out our article about what Dinan can do to these impressive little machines for a couple of bucks.

The N55 was used in vehicles such as the 535i (F10), M235i (F22), X3 xDrive35i (F25), and the X5 xDrive35i (F15), amongst others. The M2 (F87) also received a souped-up version of the N55, designated N55B30T0 – if you opted for the competition package, you received the S55B30T0 with approximately 400+ horsepower. The N55 also utilized a new DME designated MEVD17.2; the predecessor used on the N54 was designated MSD80 & MSD81 – which included the addition of FlexRay.

In addition to Valvetronic being introduced on the N55, the valve train specifications also changed slightly. Intake valve lift was increased from 245 degrees on the N54 to 255 degrees on the N55, as well as the diameter of the intake valves being increased from 31.4mm to 32mm. Intake VANOS adjustment range increased from 54 degrees on the N54 to 70 degrees on the N55. The exhaust VANOS adjustment range increased from 45 degrees on the N54 to 55 degrees on the N55. The camshaft duration of the N55 is also larger than its predecessor. The N54 cyclone separators for crankcase ventilation were deleted in the N55, mainly due to the utilization of new VANOS solenoid valves. The N54 had much more complex oil passages compared to the N55, and the oil pump was lubricated by unfiltered engine oil, whereas the N55 oil pump was lubricated by filtered engine oil.

Speaking of oil pumps, the N55 uses a modified version of the N54’s characteristic-map volume-flow controlled pendulum slide cell oil pump and for the first time, incorporated a duroplast reciprocating slide. Coolant ducts in the cylinder head of the N55 are also used for indirect fuel injector and valve cooling. The harmonic balancer was also optimized with the belt pulley sitting on the secondary disc, compared to the N54’s design – this reduced additional belt load since the belt pulley with flywheel mass is decoupled from the crankshaft by vulcanization. Only lightweight camshafts are used on the N55 as opposed to the N54, which used either cast or lightweight construction camshafts or a mixture of both. Crankshaft weight was also reduced by approximately 6 lbs – N54 & N55 engines both use cast-iron crankshafts.

The Reliability of the N54 and N55 Engines

In the end, the N55 is the more reliable option due to the refinements and alterations BMW made. It might not have the tuning potential of the N54, or the sound notes, but it’s a workhorse of an engine that seems to have less reliability issues.