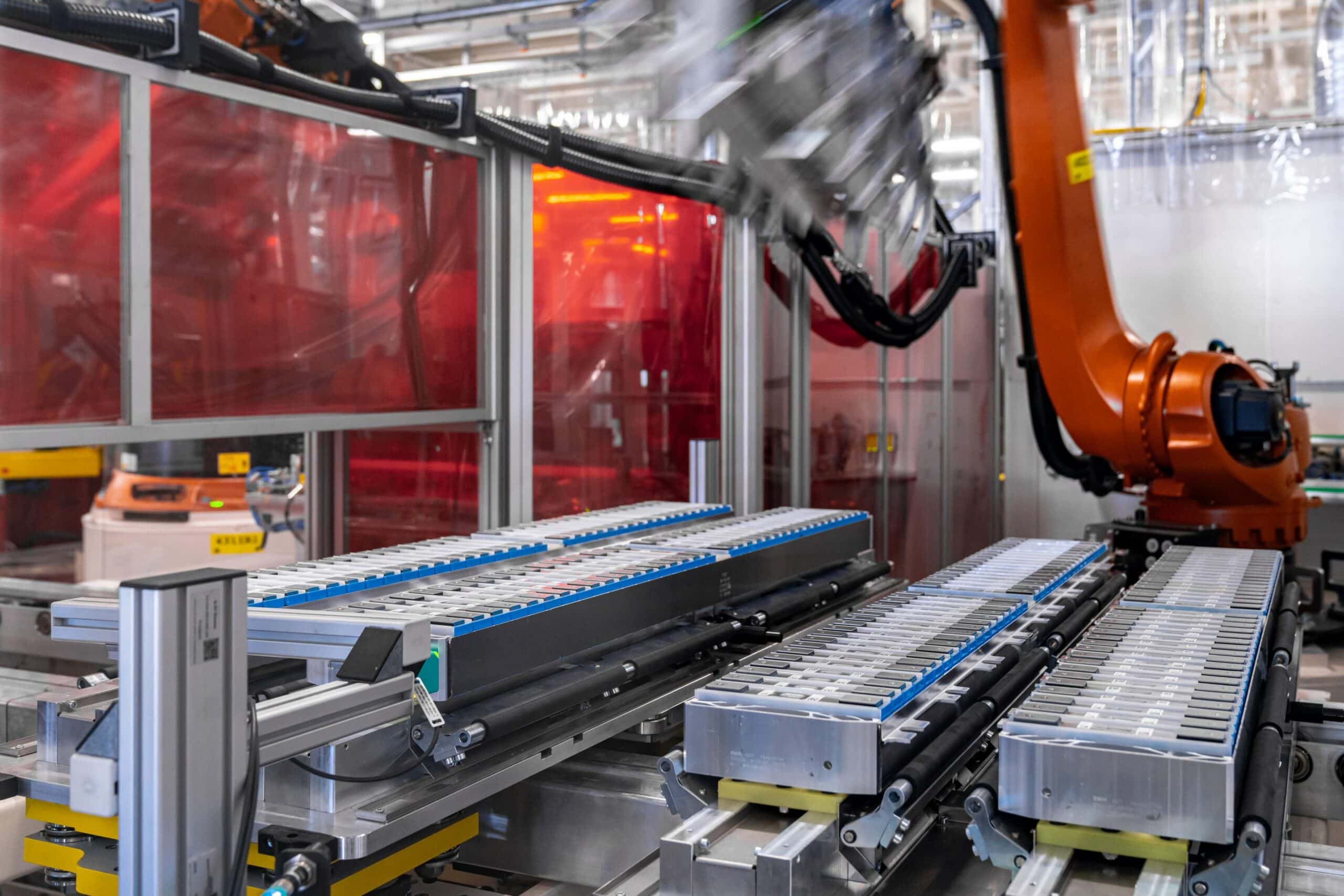

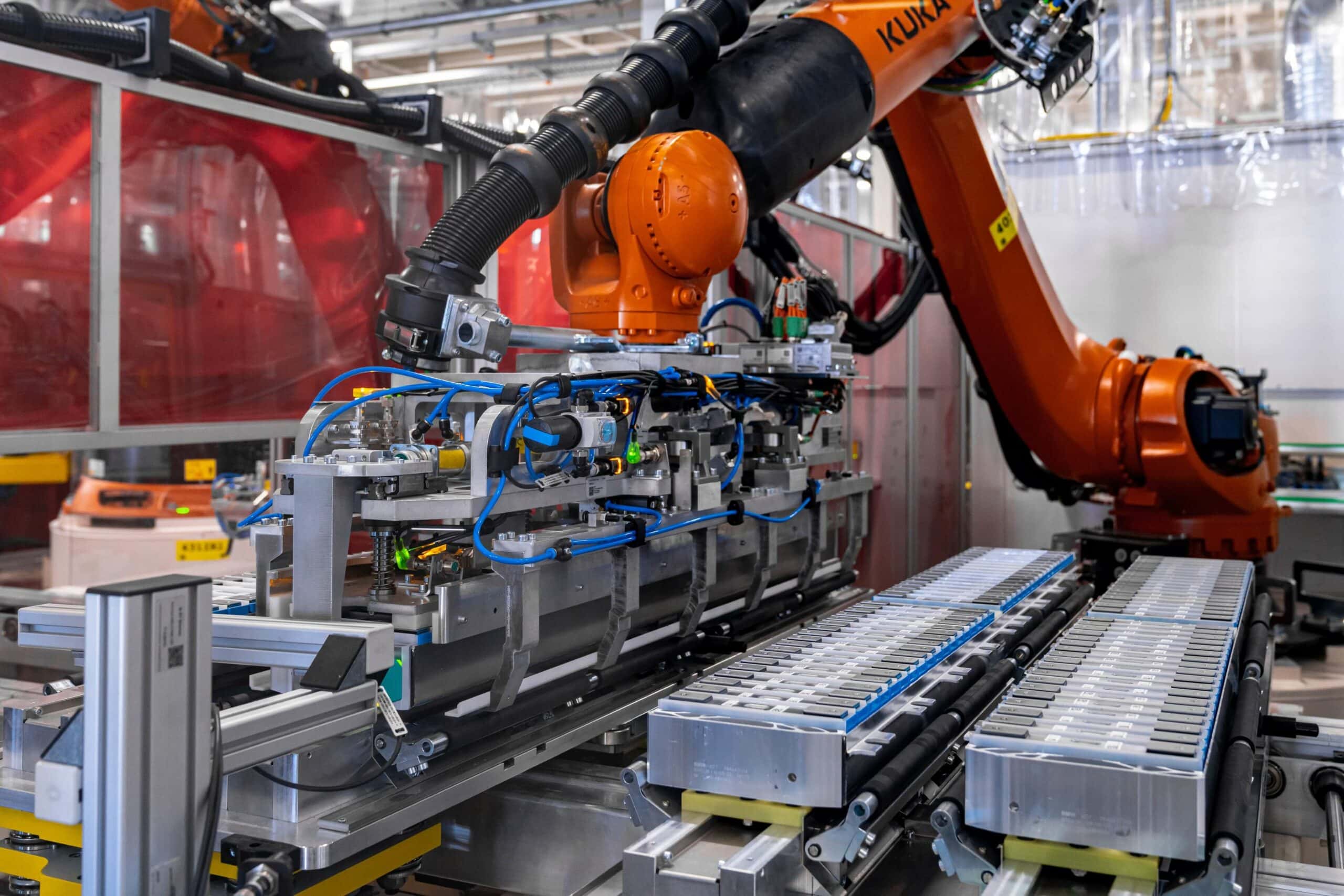

EVs have far fewer components than a vehicle powered by a combustion engine, but the high manufacturing costs with batteries are still giving automakers serious headaches. BMW is gradually addressing this issue by having more control of how the battery modules are produced for its growing array of zero-emissions models. To that end, it has invested €70 million at Plant Leipzig to manufacture in-house battery modules for the i4.

Assembly is now underway and it follows a similar step taken by BMW in May last year when it inaugurated a battery module production line in Leipzig for the iX SUV. This second battery module production line will create approximately 250 new jobs by the end of 2022 to join the 700-plus workforce already involved in making parts for EVs at the Group’s plant in Leipzig.

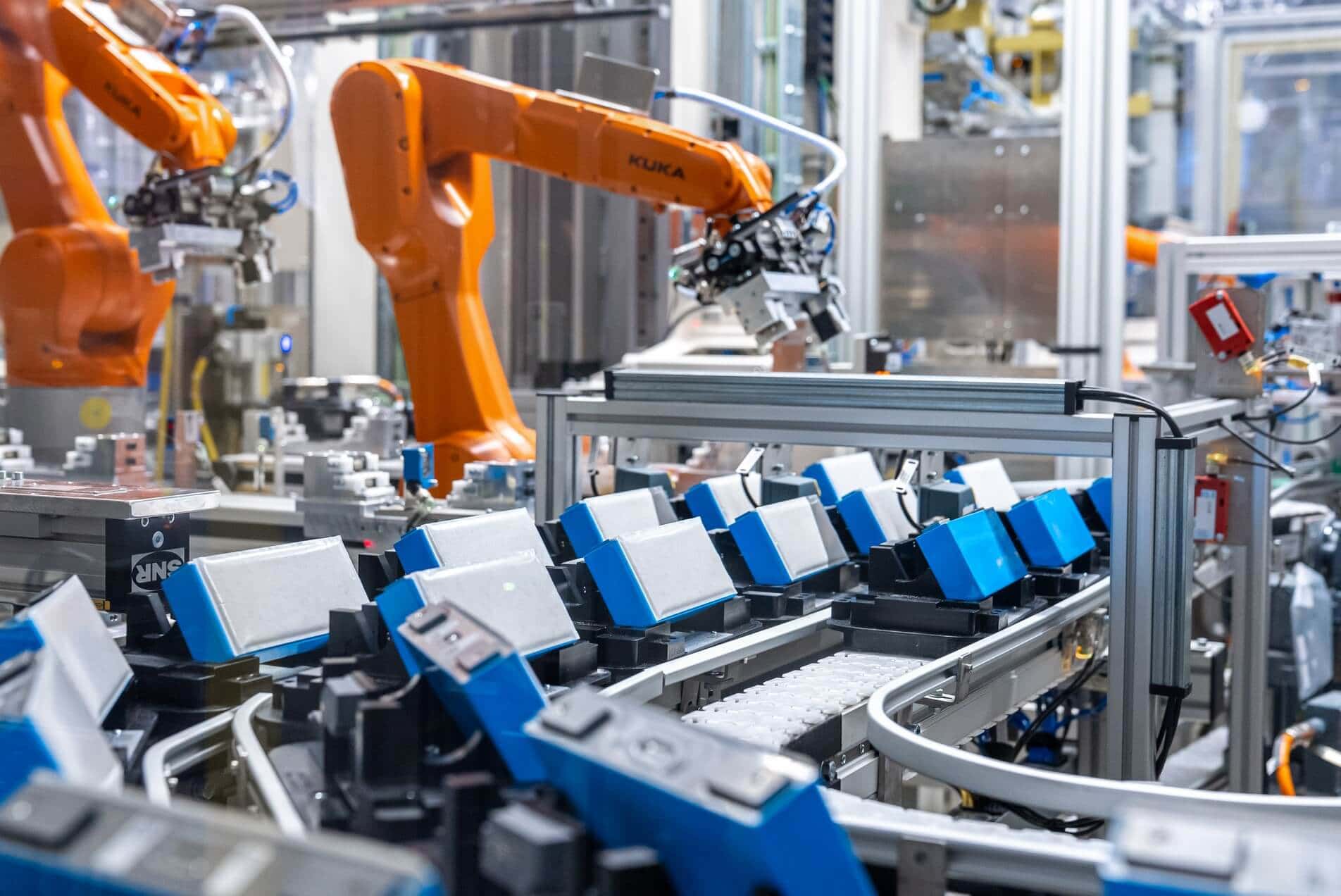

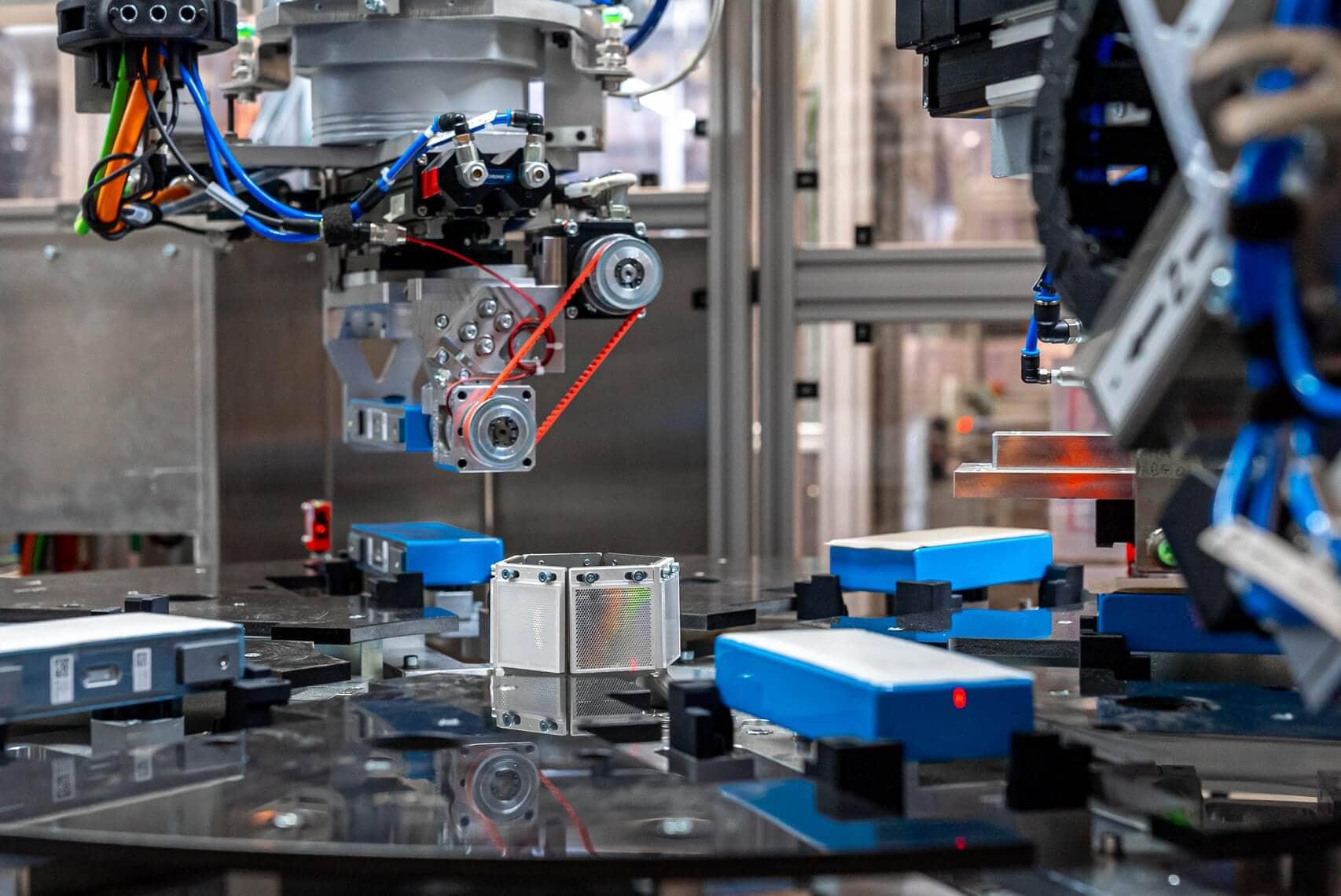

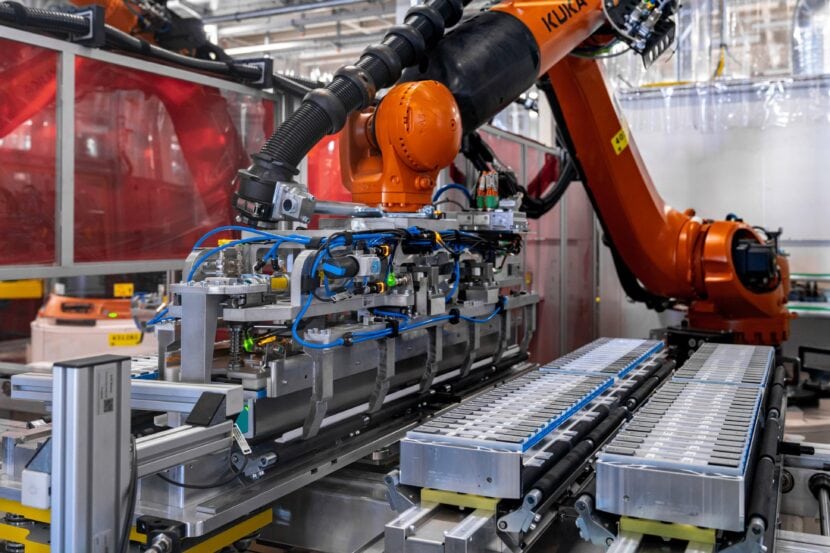

Having phased out the innovative i3 on June 30 when production of the electric hatchback ended after nine years, BMW decided to utilize the newly available capacity to intensify its battery manufacturing efforts. The new battery module production takes up an area of around 4,250 square meters where there are no fewer than 196 production stations. The battery module goes through all of them before it’s ready for additional processing.

To keep costs in check, BMW has localized production of e-drive components by making the necessary hardware at its own facilities in Dingolfing, Leipzig, and Regensburg at home in Germany. These are also produced in Spartanburg, United States, and in Shenyang, China, while high-voltage batteries are being put together in Thailand as well for the Rayong plant.

The next order of business is to open a Cell Manufacturing Competence Center in Parsdorf outside of Munich to perfect the series production of lithium-ion battery cells and ensure a cost-effective method of mass production. All these steps are being taken as part of BMW Group’s greater goal to have EVs account for at least 50% of all sales by the end of the decade when Rolls-Royce and MINI are set to go electric-only.

Source: BMW