Even though it may not seem like it, BMW started working on electric cars quite a long time ago. Back in 2013 the BMW i3 came out, the first electric car from Munich, and even that car required a lot of research and development in this field, years before. Therefore, it would be safe to say that BMW has been developing technology for electric cars for at least ten years. That should be well reflected in the way the upcoming BMW iX performs and we’re very curious about it.

One of the things future electric cars from BMW will use is the eDrive module. This is basically a single unit made up of the electric motor and batteries that’s very modular and easy to make. Eventually, this single unit is also very scalable, being used in a variety of cars, cutting down costs and complexity. In order to develop it and other technologies, BMW opened a research hub in Dingolfing, a so-called Competence Center.

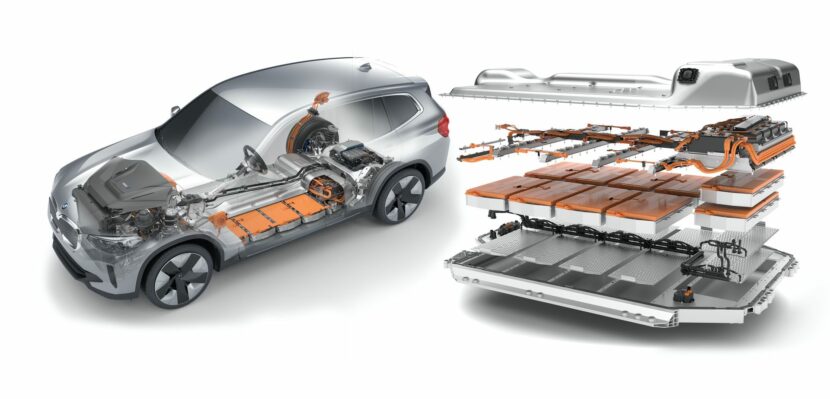

This is where research in the field is being carried out but also where manufacturing is taking place, looking for the best technologies out there. The video below offers a small glimpse into how the process of assembling the batteries and electric motors altogether goes down in the Dingolfing plant. It’s quite interesting to watch too, as it shows the battery cells being nested together and the wiring being added on top, with them being sealed off afterwards in a compact unit.

That unit will make up the floor in the upcoming BMW iX. Just like it’s the case with most electric cars out there, on the upcoming electric SUV we will see a similar approach, done in order to keep the weight of the car as close to the ground as possible. A lower center of gravity will always help out in terms of driving dynamics and when it comes to a BMW, that actually matters. Until we get to drive the iX, let’s see how some of it is made.

https://youtu.be/giEOuFNfTfo