BMW has been recently criticized for “bloating up” their cars and moving away from what once was the Ultimate Driving Machine, at least according to the pundits. And while that might be true – regarding the weight – there are lot of factors that go into the production process of a car. And weight, it’s certainly an aspect that every BMW engineer would love to keep as low as possible. We won’t get into the full benefits of a low weight car, but certainly, driving dynamics is one of them.

From Concept To Production

The BMW i8 serves as a prime example of BMW’s meticulous approach to managing weight in their vehicles. Originating from the BMW Vision EfficientDynamics project in 2010, the i8 initially set a specific weight target, which in concept form looked achievable due to the absence of production car crash systems and electrical architecture. However, transitioning from concept to production proved to be a complex endeavor.

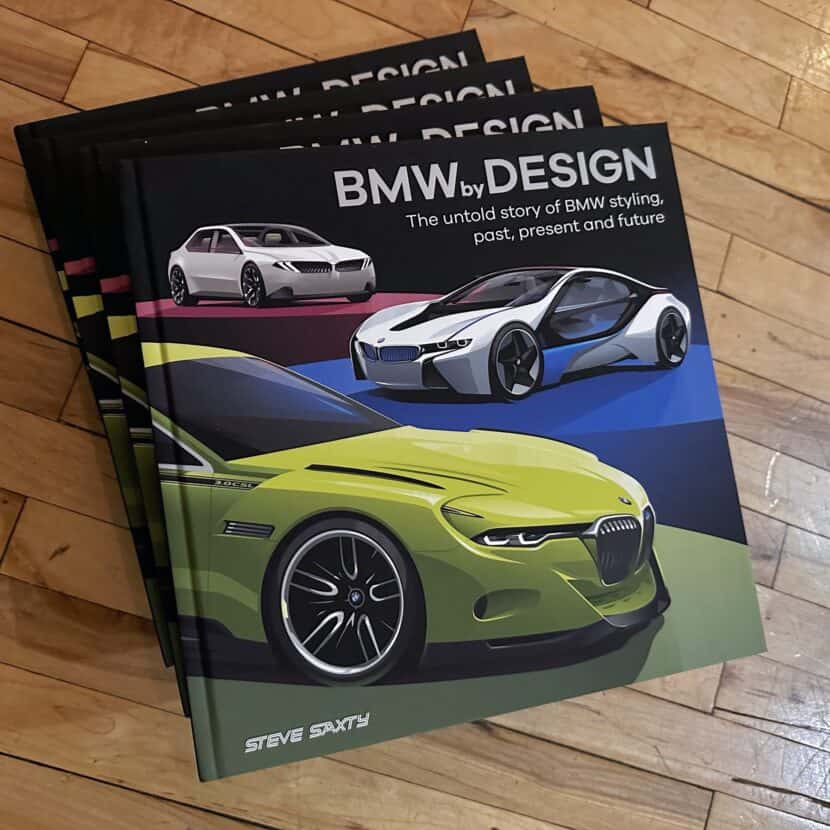

Under the leadership of former BMW engineer Carsten Breitfeld, the production team faced a tight 36-month deadline to ready the i8 for production. This entailed comprehensive revisions encompassing packaging, legislative requirements, manufacturing feasibility, and, crucially, cost and weight considerations. Steve Saxty’s book “Hidden Gems” emphasizes the necessity of controlling both weight and costs, particularly for a low-volume, high-performance sports car.

There is More To Design Than Sketching

Central to this process is the collaboration between the design and engineering teams. While designers aspire to create visually striking cars with a “WOW” factor, the realities of car manufacturing demand alignment with engineering and production constraints. Contrary to popular belief, design changes are not merely a matter of altering lines on a sketchpad, or swap a light unit for another. According to Benoit Jacob, former head of BMW i design, and the man responsible for the i3 and i8, any deviation in design can unsettle engineering colleagues, as demonstrated by a minor adjustment to the BMW i8’s front end.

“I came into the studio one day to look at the clay,” says Jacob, referring to the BMW i8. “And thought it just needed 10, or so planform on the front.” His lead designer Mario Majdandzič agreed and made the change with the modeler. The only caveat? The engineering team was left out of the loop. At the next weekly review meeting, the engineering team noticed the car grew in size. Keep in mind, we’re talking about 10 mm, which is 0.39 inches.

Finding A Way To Shed 40 Grams

While the car now looks great, that little change – at least to us – it had some weight implications. The module leader of the bumper – yes, there is a person in charge of almost every single part on a car – said he would have to add 120 g of plastic and aluminum. The book doesn’t specify the reasons behind that, but we’re guessing it had to do something with crash requirements or stiffness of the car. Securing approval for such changes requires authorization from the BMW Board, which, in this case, was given to the design and engineering team. But that approval came with a requirement: offsetting the increased weight by reducing 40 g elsewhere.

In a display of engineering ingenuity, BMW engineers identified the windshield wiper arm as a target for weight reduction. “So what did they do? They drilled three holes in the wiper arm to reduce the weight,” explains the book. Of course, we would never notice that in real life, but the clever weight reduction meant we got a better looking car. At least according to the designers.

Not Every Youtuber Can Be A Designer

As highlighted in “Hidden Gems,” the glamour of car design belies the complexities involved, encompassing cost control, legal compliance, and weight management. Critiquing designers without acknowledging these intricacies undermines the collaborative efforts shaping automotive excellence. The next time criticism arises on social media, it’s imperative to consider the multifaceted nature of automotive design and production.

If you’re interested in some BMW design behind-the-scenes stories, then grab the “BMW: Behind The Scenes” three-volume boxed set which will be available soon – at a pre-order price of $299.95/€270/£78.11. Alternatively, the principal book, “BMW by Design” is available immediately for $99.95/€90.02/£88.10; all with free shipping in USA, UK and EU.