BMW announced that it is introducing a new painting technique at its Dingolfing plant, meant to reduce waste and energy consumption. The new process also allows customers to further customize their brand new cars by offering several new colors. The overspray-free painting process will be used for the first time on a small batch of 19 BMW M4 Coupe models that will feature two-tone paintwork.

“We expect the highest standards of efficiency, sustainability and digitalisation from our production. This smart painting technology meets all the requirements for an innovative production process and also offers unique customer benefits,” said Milan Nedeljković, member of the Board of Management of BMW AG, responsible for Production upon the announcement.

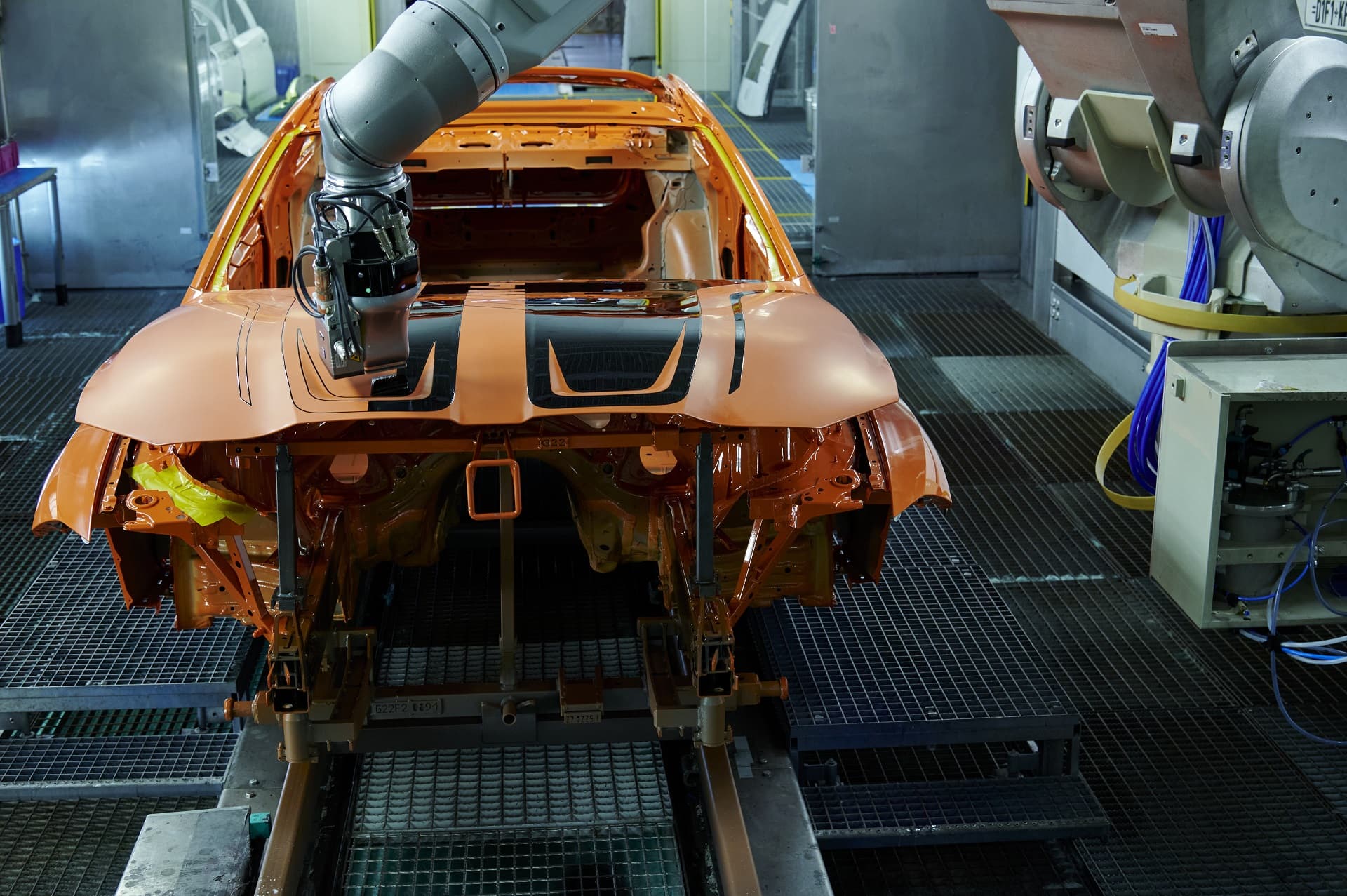

In the conventional procedure, paint is atomized by a rotating bell with 35 to 55,000 revolutions per minute and adheres electrostatically to the body. The new method works without electrostatics, relying instead on jet application. The paint is applied using an orifice plate that enables high edge definition with a variable paint thickness of between 1 and approximately 50 millimeters.

This requires maximum precision from both the robot and application technology. It also means two different colors of paint can be used, for instance for a contrasting roof, and stripes and other designs applied – for example, on the bonnet. The focus of technology and material development was on achieving the maximum range of applications. It will now be possible to paint every exterior component – offering customers virtually limitless options for individualization.

Until now, custom designs like this can only be realized using manual masking. With the new technology, the material and personnel costs this previously entailed will be eliminated, making it possible to realize these options at a lower cost. This process also prevents so-called overspray, excess paint particles, which therefore no longer have to be disposed of. A further contribution to sustainable production comes from lower energy consumption.

Since paint separation is no longer required, the amount of air needed is also lower. At around 7,000 operating hours, this results in energy savings of more than 6,000 megawatt hours and reduces the carbon footprint by nearly 2,000 tonnes per year. At first, this process will be used on BMW’s own fleet of cars but it is intended to be offered on a wider scale beginning with 2022.

https://youtu.be/TENdqqyv2YU