The automobile has been amongst us for over a century. And automobility has been obtainable for the middle class since the end of World War I, especially in the US, thanks to Henry Ford’s Model T.

In the beginning three modes of powering prime movers were in competition. The first was the external combustion – steam engine. Successfully ‘miniaturized’ in the late eighteenth century, steam engine road going vehicles could be seen on British post roads – but the technology (and safety) hadn’t caught up, nor were the roads up to carrying the enormous weight of the steam carriages. Hence the evolution of the iron railed road. Steam cars reappeared in the early twentieth century, but they were extremely inefficient compared to electric motors or internal combustion engines, not to mention the maintenance requirements and the amount of fiddly bits to monitor while underway.

I had an opportunity to ride in the front seat of a Stanley steamer twenty years ago and it was a revelation. It took no short amount of time to get the boiler to produce steam (a watched pot never boils) and that had to occur before we could move. Once underway – while we whizzed along a dirt road at what I thought was an alarming speed, near 60 MPH – the driver was constantly adjusting a myriad of controls to ensure relatively smooth operation. It was a pretty demanding workload on a driver. The Doble steam car – made from 1909 until 1931 – attempted to alleviate some of those disadvantages with a fast firing boiler and only four controls, three pedals, and a steering wheel. And it was probably the pinnacle of steam car evolution. Regardless, steam power for automobiles proved to be a dead end. The last semi-serious attempt to develop a steam car was half a century ago, Bill Lear’s (of Learjet and 8-track fame) Vapodyne.

Another contender was the lead acid battery powered electric car – with an ultra efficient electric motor supplied with power by batteries, the electric car was poised to take over urban transportation from horse drawn hacks around the turn of the twentieth century. But bad business decisions and the limited energy density by weight of lead acid batteries spelled the death knell of electric power in the formative years of the automobile. Although for simplicity of operation the electric car was king. Not to mention, with the advent of brushless motors, maintenance is a virtual breeze.

It was the gasoline – and later diesel – fueled internal combustion engine that, thanks to operating range, rate of refueling, and performance, prevailed. And it is the range and rate of refueling issues that has kept the promise of the electric car from being fulfilled. Given a gasoline engine’s less than stellar efficiency, at best around 35%, and maintenance issues, the saving grace is the energy density of the fuel used to power the motor.

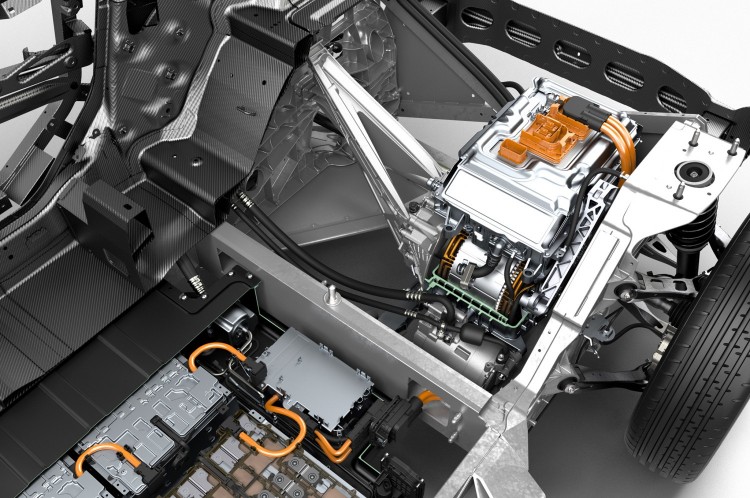

The rub with electric vehicles is the rate of recharging and range – the electric motors themselves are absolutely great. Electric motors for cars are usually over 95% efficient, compact, and – because of the wide fat and flat torque curve – require just a single speed transmission gear (with provisions for reverse, of course). What has let the electric motor down is its fuel source; the battery.

A battery is a storage device. It is comprised of a negative terminal, anode, and a positive terminal, cathode, and an electrolyte (in the form of a liquid, a slurry, or paste) to facilitate the movement of electrons in the battery. Put a load, via an electrical circuit, on a battery and the flow of electrons start from the anode to the cathode through the circuit. It is that flow of electrons that is the ‘fuel’ for electric motors.

The load presented by the electric motor is resistance, the arrangement of cells in the battery (whether in series or parallel) determines the voltage and amperage available. The electric motor uses electromagnetic principals to perform work – and as previously mentioned is extremely efficient.

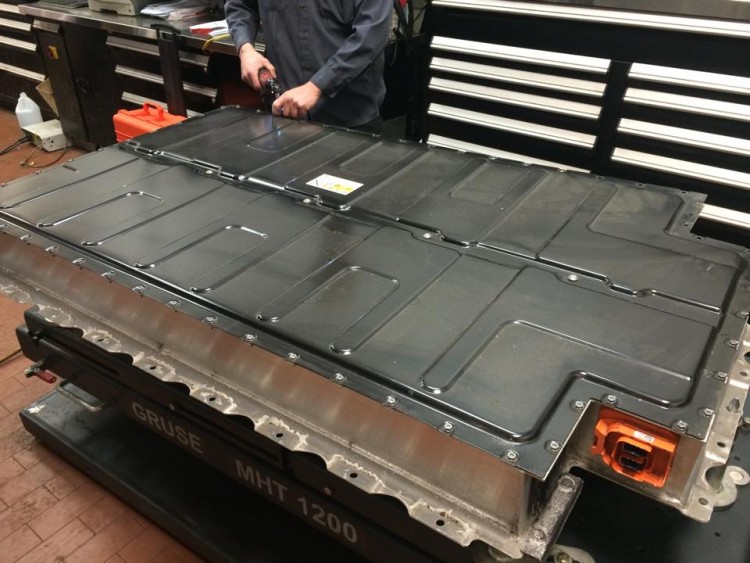

Lead acid and nickel metal hydride batteries have been superseded for use in electric vehicles by lithium ion batteries. While both the lead acid and Ni-MH batteries have their uses, the better energy density of Li-ion batteries has lead to their widespread adaptation for electric vehicle power storage.

Then there are the metal-air batteries, in actuality fuel cells, that are beginning to appear feasible. Lithium-air and aluminum air are being touted as the next big thing – offering substantial increases in electric vehicle range. However, in the case of the aluminum air battery, there are a number of technical issues that need to be resolved as well as the device has to be swapped out rather than merely recharged. It has to do with how the metal is used. In essence at the end of its ‘charge’ you’re left with oxides of the metal that no longer hold a charge. When you need to refuel you end up swapping out a battery pack.

On a good note though, they will provide outstanding range – up to eight times what we are currently seeing, and good weight savings (further enhancing range). At the moment these are currently in development stages. And they may be in competition with the hydrogen fuel-cell – though they could benefit from a breakthrough in the membranes used to isolate electrons.

Breakthroughs have been promised for batteries and are announced regularly, but as is too often the case, they prove to be a chimera – an illusion. And until batteries or fuel-cells can deliver about four to five times the current energy density of Li-ion batteries, gasoline and diesel will remain undefeated.

The question of what is driving electric car sales however appears to be government intervention in markets, through use of tax incentives and subsidies. If you have been to Norway recently you’ll be amazed at the number of Teslas on the road. Norway uses tax dollars and tariff relief to subsidize electric vehicle purchases – and it shows. Without governmental intervention and incentives, given the range and rate of refueling issues, electric vehicles would be about where they were a century ago, a promise yet fulfilled.