The specialist areas of M engineer Bernd Barbisch: Development and testing of conventional and regulated spring/damper systems and axle/elastokinematics. His department also had a major role to play in the development of the rigidity package for the new BMW M3 and BMW M4.

Also see Albert Biermann, Head of BMW M Engineering, explaining the chassis of the new M3 and M4.

Mr. Barbisch, the BMW M3 that has now been replaced already had an excellent suspension …?

Bernd Barbisch: The previous BMW M3 already offered a very good suspension basis. It was a benchmark – the one to beat.

How?

Using intelligent lightweight construction we were able to take a considerable step forward in terms of driving dynamics.

The role model here was the BMW M3 CSL, where reduced weight again permitted an increase in potential transverse dynamics.

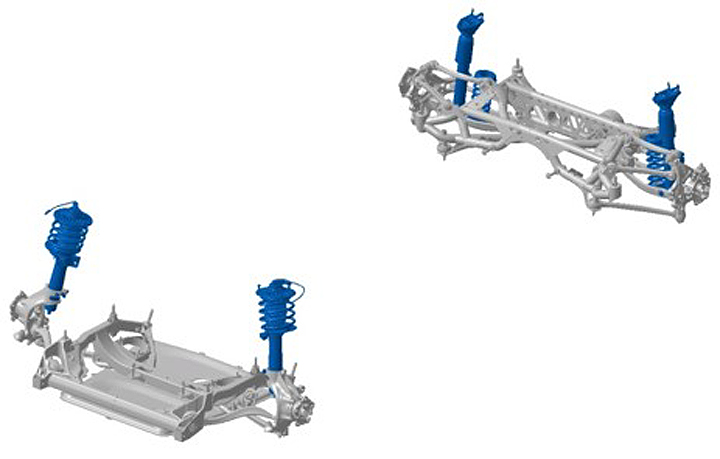

The axle design is completely new and entirely M specific, in other words no parts have been adopted from the base model. This elaborate design significantly enhances performance, driveability and response.

The premise was to maintain the good driveability of the previous BMW M3 but considerably increase performance at the same time. You’ll be able to see this in the lap times achieved.

The new BMW M3 and BMW M4 are now offered with two different damper systems again: the standard suspension and the controlled Adaptive M suspension. What’s new?

In the standard suspension there are new dampers. They enable much less phase shift in response as compared to the predecessor system, and therefore even more grip. Customers will notice this clearly when driving over poor surfaces, for example.

What does “less phase shift” mean?

A damper converts a speed into a force so as to keep the wheel on the ground. The faster the wheel passes through the rebound and compression phases, the greater the force. If you look at this in terms of the frequency of superstructure excitation and wheel excitation, the correct phase between speed and force is now applied across a much expanded operating range. When the phase between excitation and damping is not right, the damper becomes a spring at some point – increased wheel load fluctuations occur and road surface contact is impaired.

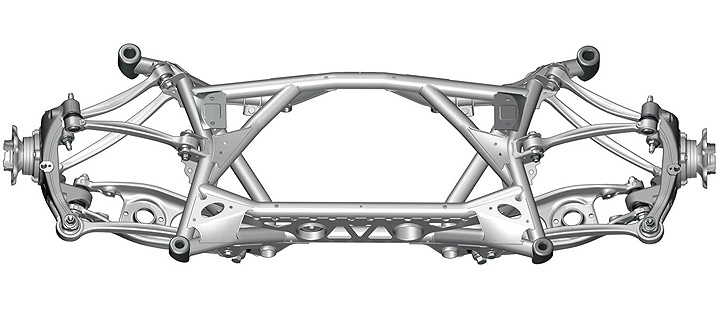

Rear axle control arm and wishbone optimised for rigidity and weight in the BMW M3 and M4, in aluminium forging technology.

And in the Adaptive M suspension?

In this regulated suspension we wanted to at least equal the comfort of the predecessor model but also achieve a clear increase in sportiness.

For this purpose we are using an even more effective system of sensors in the car. For example, there are now wheel acceleration sensors at all four dampers which assess the state of the road surface, so to speak. Based on this data, the damping is recalculated and regulated at every damper every 2.5 milliseconds so as to set the optimum level of damping force – and that can vary considerably between each of the four wheels. So the damping at one wheel could be considerably softer, while at another it might be much tighter.

Forged aluminium rear axle wheel carrier in the BMW M3 and BMW M4.

Our regulation approach is the so-called “skyhook”: the regulation strategy applied by the damper logic ensures that the automobile is always guided by the sky, if you like. Here the damping is regulated based on the movement of the entire automobile. With other regulation elements we then create the best possible connection with the road. In addition there is a new sensor cluster used in the vehicle which measures lift, pitch and roll acceleration, thereby registering the movement of the car’s superstructure. The automobile moves more calmly and supremely.

The regulated damper itself has also been refined. We are now able to achieve a much greater spread in the damping – especially in terms of the direction of pressure. We went to the limits of what is possible with damper technology so as to achieve optimum race track performance combined with everyday practicality. And the dampers are much lighter than in the base model due to the fact that they are made of aluminium.

A so-called 3-path support bearing is now used, too. The damper has its own power transmission path to the body – the forces of the bearing spring and the ancillary spring are transmitted rigidly via separate paths.

What is the advantage of this?

Previously the ancillary spring could shift the bearing when the wheel was compressed – this meant the damper was not always in the ideal operating range. The decoupling means that the damper now operates perfectly in phase, regardless of whether the wheel is in compression or rebound. In this way we achieve maximum body cohesion.

Which of the modes COMFORT, SPORT and SPORT PLUS of the Adaptive M suspension can the standard suspension best be compared to?

That’s a relatively difficult question to answer. Due to the elaborate regulation logic and sensor system, the Adaptive M suspension is able to achieve superstructure cohesion and increased comfort at the same time. This is usually the conflict you always have with the suspension set-up: achieving the best possible cohesion so as to be able to run on demanding tracks like the Nürburgring Nordschleife as fast as possible, for example – but also retaining the required amount of comfort for everyday driving. The car mustn’t demonstrate any after-response or pumping, let alone take off over hollows and crests. In terms of superstructure cohesion, the standard suspension is somewhere between SPORT and SPORT PLUS, in terms of comfort it is more equivalent to SPORT PLUS.

Leaving the aspect of comfort aside, which is important in everyday driving, and just looking at the car’s driving dynamics qualities: is the Adaptive M suspension superior from this one-sided point of view as well?

In the standard suspension we tried to achieve the best possible compromise over all possible race track profiles. In the case of the regulated Adaptive M suspension, even more individual adaptation is possible here. On the Nürburgring Nordschleife I personally use SPORT mode. On a fairly level race track, however, SPORT PLUS would be the best choice.

In any case: with extreme grip potential, the new BMW M3 and BMW M4 still remain very driveable at all times.

The data measured by the sensors impacts dynamically on the suspension set-up. You might say that the standard suspension is set up once, while the Adaptive M suspension is set up every 2.5 milliseconds?

(laughs). Correct.

Can this result in an overlap of the setting ranges? In other words, even the COMFORT setting could lead to the suspension being tightened significantly if required by the relevant manoeuvres?

There are manoeuvres where the COMFORT setting is just as sporty as in SPORT and SPORT PLUS. Maximum damping power potential is used here, regardless of the setting.

What manoeuvres are these?

You already mentioned that you yourself use the SPORT on the Nürburgring Nordschleife and SPORT PLUS on level race tracks. What about when you’re driving in everyday traffic …?

There I definitely use the COMFORT setting. (laughs). The new BMW M3 and BMW M4 now start for the first time in SPORT mode. My M1 button at the steering wheel is pre-set to DSC OFF, with steering and dampers in COMFORT.

Last year you were at Nürburgring doing set-up runs with the DTM driver Bruno Spengler. How did that go?

It was remarkable how quickly Bruno felt his way to the limit. And that’s what is so striking about the BMW M3 and BMW M4 for the normal driver, too: the car always remains eminently driveable in spite of the extreme grip potential. That’s always the difficulty in general: the closer you get to the physical limits in terms of the car’s balance, the greater the challenge in getting the car to respond quickly. As you can see in the new BMW M3 and BMW M4: the driver simply gets in, drives off and can immediately drive fast, on the race track for example. And that’s a key aspect of the M philosophy: driving response and the car’s reactions always have to be predictable and convey a sense of trust.

Did the test runs with Bruno Spengler and Timo Glock contribute to achieving this?

Bruno had an idea regarding the transverse rigidity of the tyres and we implemented that. Ex-Formula 1 driver Timo Glock’s input in terms of the steering was also taken on board.

It was exciting to see how much overlap there was between the racing drivers’ point of view and that of our set-up experts and how quickly they came together.

Mr. Barbisch, thank you very much for the interview.