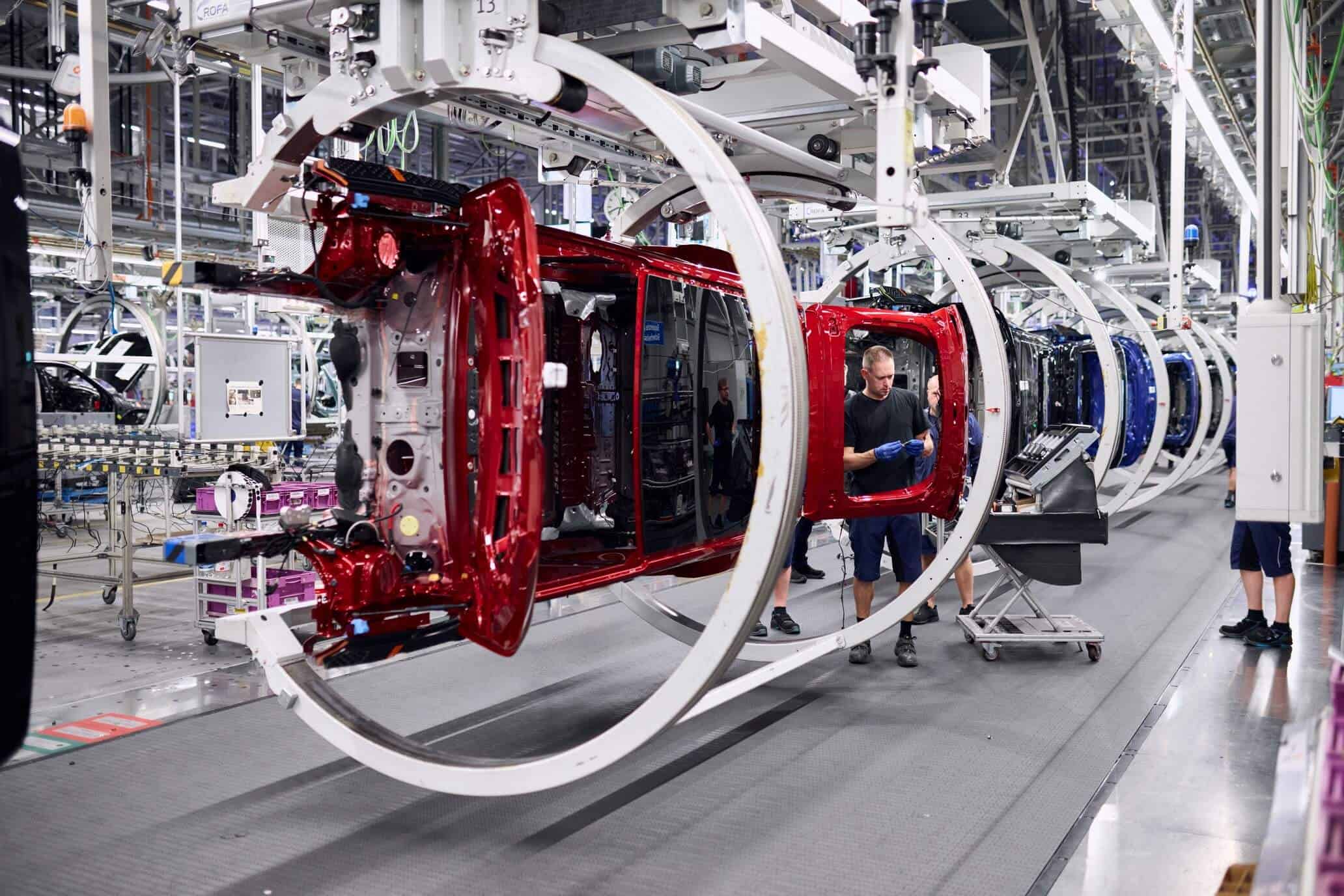

A factory that produces cars, or just about any other factory for that matter, must run like clockwork to maximize output. Any unscheduled stoppages cost companies large amounts of money, not to mention customers are forced to wait longer than planned for their products bought with hard-earned money. BMW wants to minimize disruptions as much as possible by using artificial intelligence at its Regensburg plant in Germany.

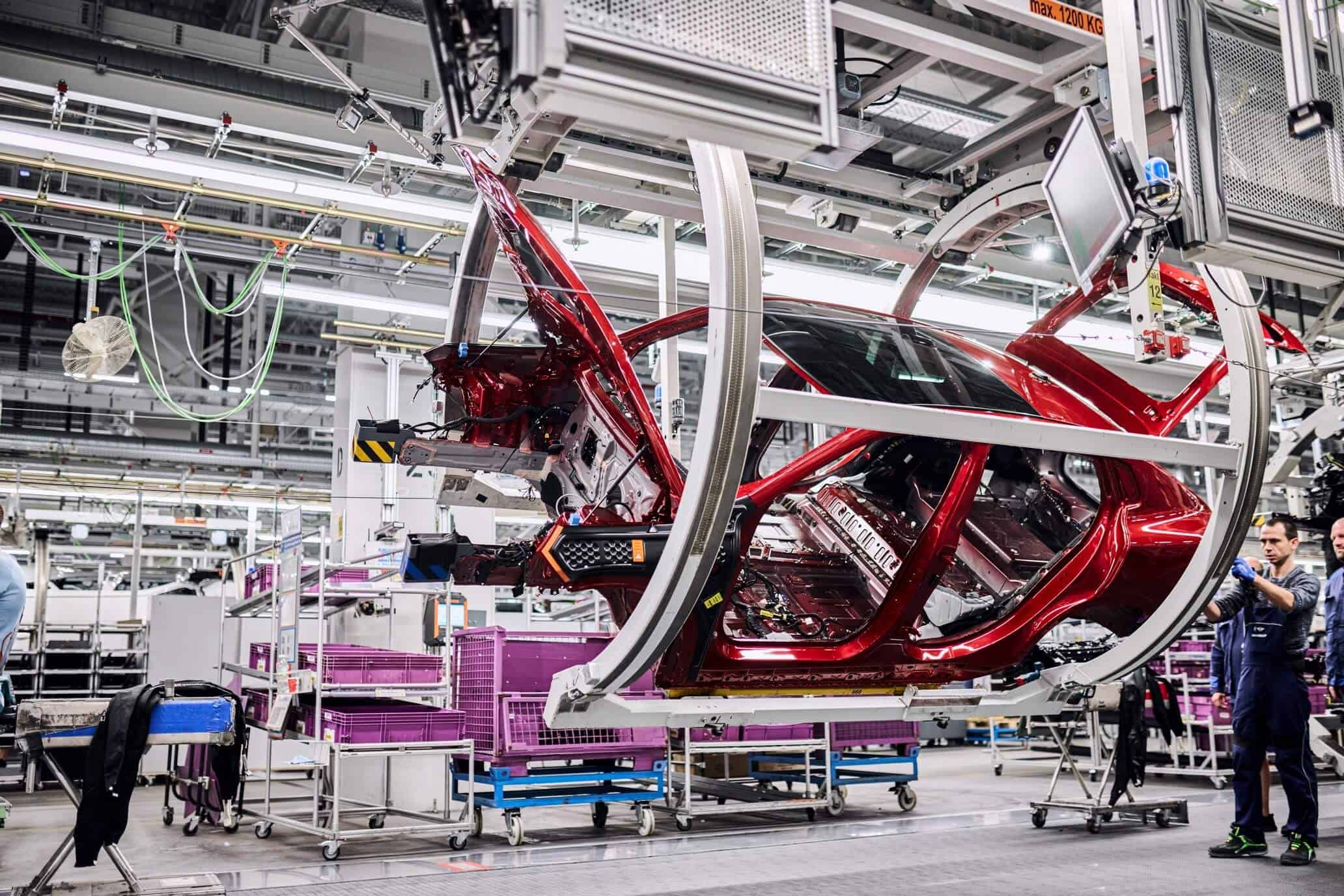

The luxury automaker has implemented a smart analysis system that performs predictive maintenance. How does it work? AI does data-driven analysis of conveyor technology while cars are assembled. Any faults that might occur are detected early, and ideally, BMW can fix the problem before it disrupts the workflow. In the future, the company hopes to improve the tech so that it can estimate the time remaining between the moment when a fault is detected until there’s a risk of an actual stoppage.

This AI-supported monitoring system has been developed in-house by the BMW Group, which has already registered two patents pertaining to predictive maintenance. The algorithm has been created to constantly try and find irregularities in the production cycle, such as fluctuations in the conveyor’s power consumption or irregularities in its movement. The algorithm can also detect when barcodes are not legible enough. When errors are found, the maintenance control center automatically receives a warning message for the person on the job to address.

According to the company’s estimations, implementing this AI-based monitoring system eliminates about 500 minutes of disruption each year at the Regensburg factory alone. Every minute counts if you consider a vehicle rolls off the assembly line every 57 seconds. Conveyor systems with integrated AI tech are also in use at factories in Berlin, Leipzig, and Dingolfing.

Predictive maintenance not only helps BMW maintain a smooth workflow at the factory but it also drives down production costs since it doesn’t have to spend extra on sensors. The only expenditures are for the computers and storage devices to hold analyzed data.

Source: BMW