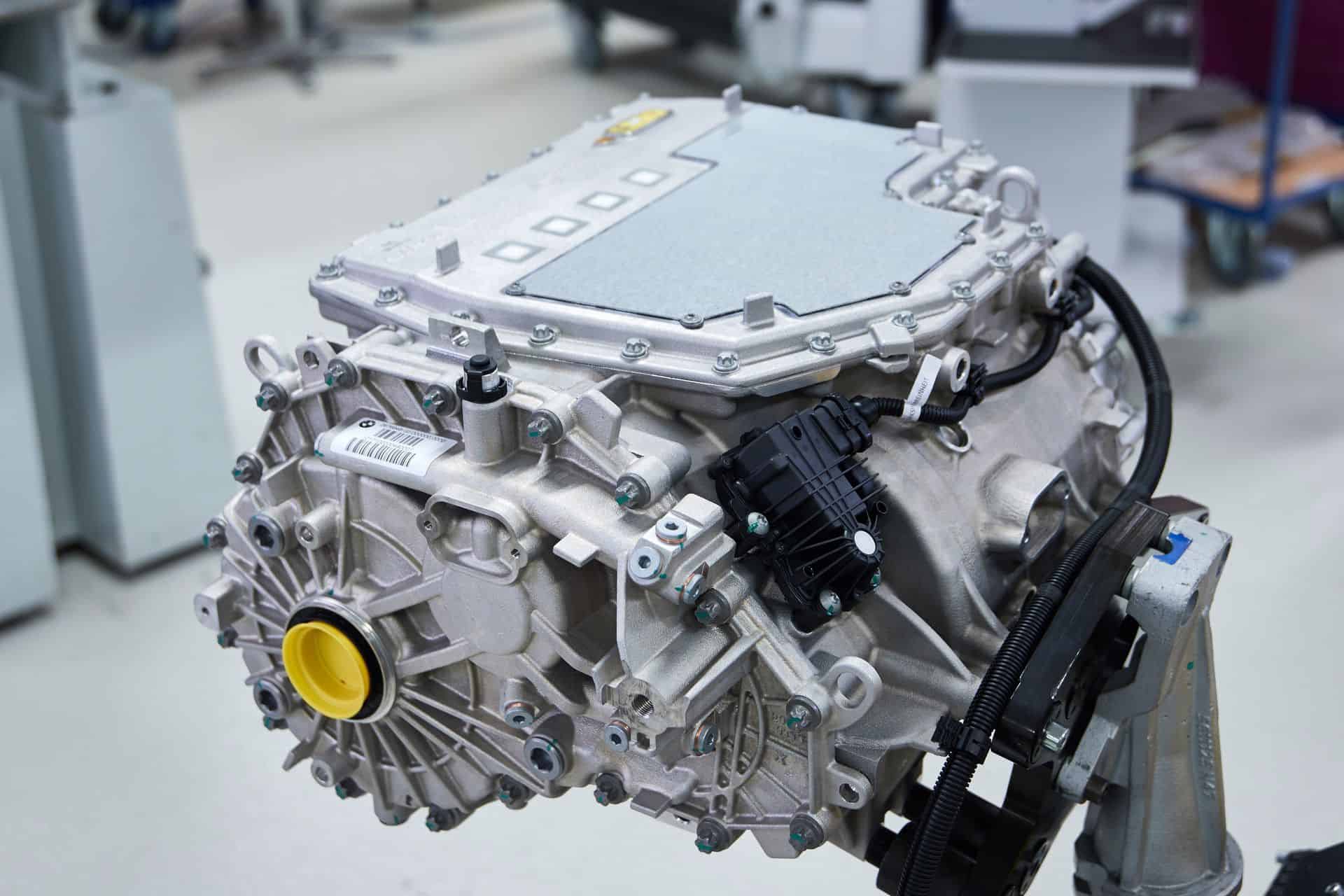

BMW has been developing electric vehicles for over 50 years, and for its most recent fifth-generation eDrive powertrains, the automaker has started using a new and special type of electric motor that has a whole host of advantages. It has features of both synchronous and asynchronous electric motors, it uses no rare-earth materials, and it even can make the car’s wheels vibrate when launch control is enabled for that extra dose of excitement that EVs need.

BMW’s Externally Excited Synchronous Motor (EESM)

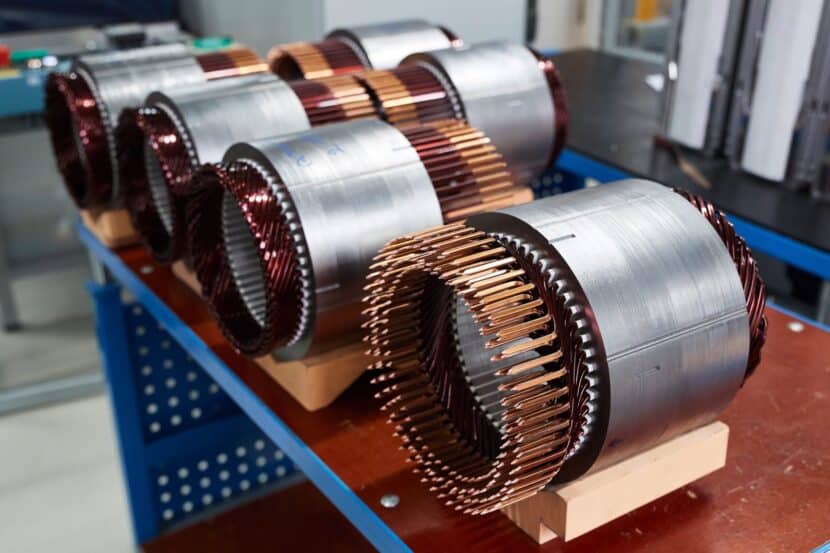

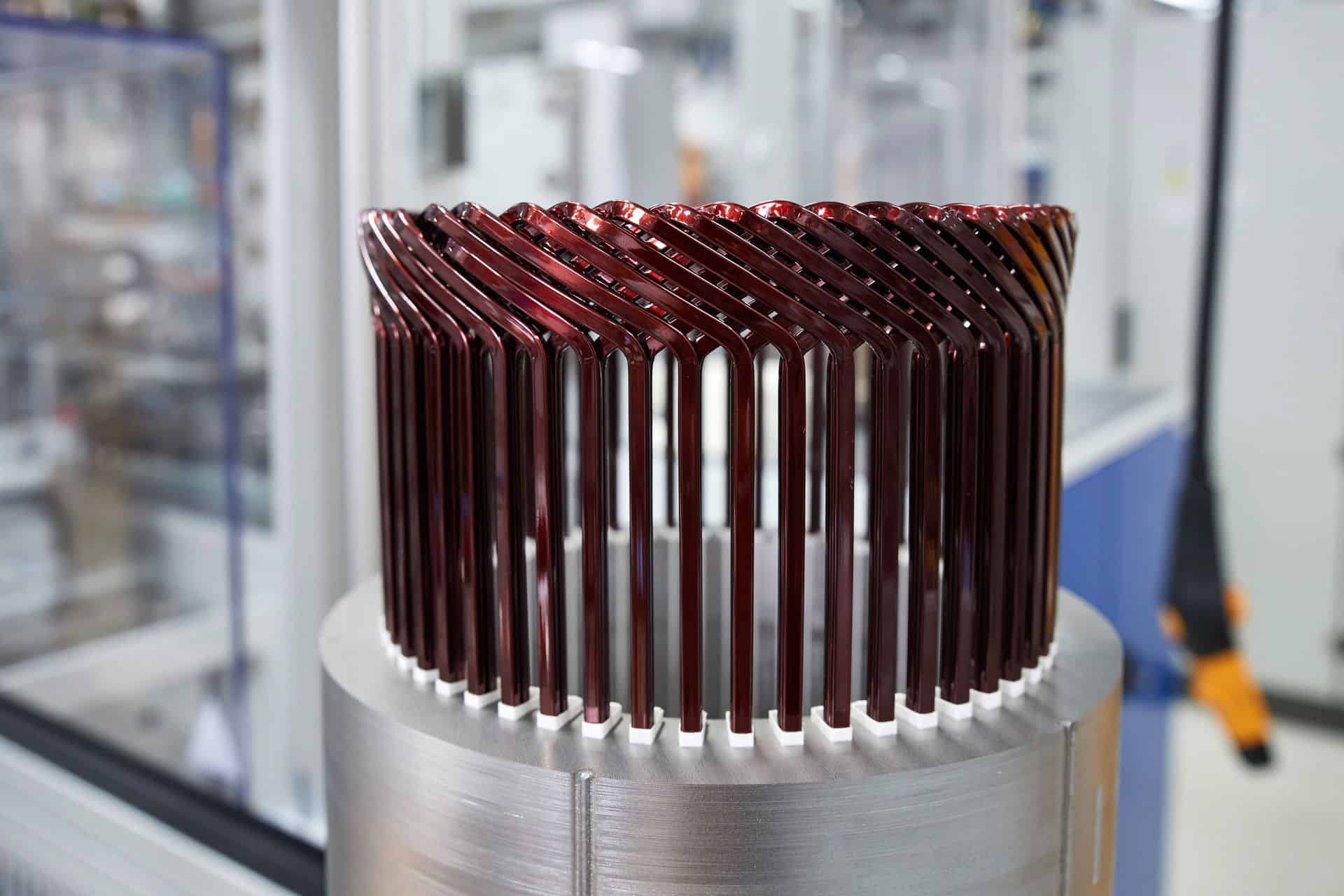

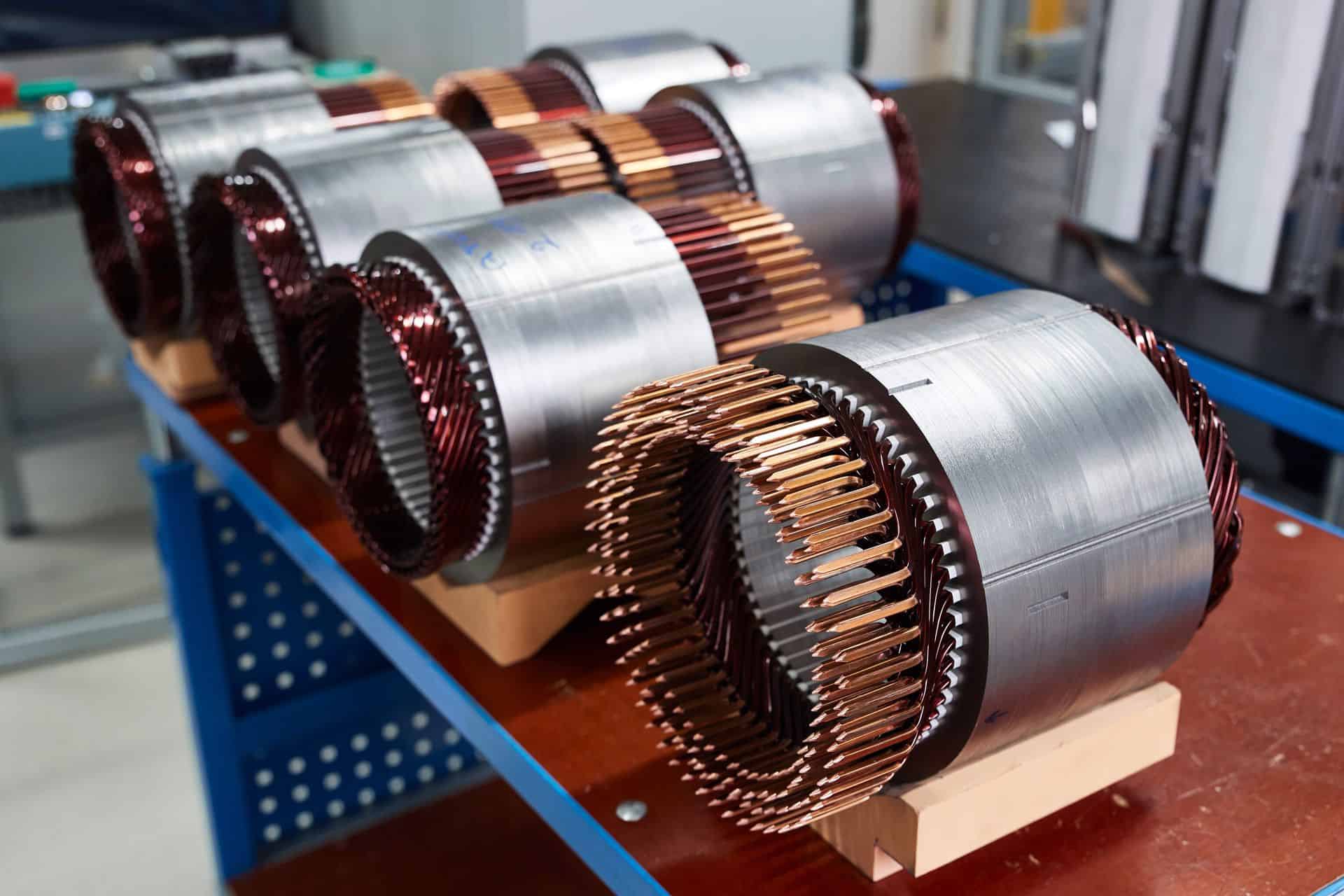

The manufacturer calls it an externally excited synchronous motor, and everything you need to know about it is in its name. It’s a type of brushed motor (different from the brushless variety used by Tesla and other EV manufacturers), but instead of two or more permanent magnets in its rotor, it has a coil. This means a magnetic field is generated on demand only when the coil is powered, as opposed to the more widespread version of this motor, which doesn’t give you the ability to turn it off.

Carmakers seem to have almost unanimously agreed that the best current type of motor for an EV is the permanently excited synchronous machine (PSM). However, since they are essentially always providing resistance and don’t allow the vehicle to coast, manufacturers have implemented a clutch that physically decouples the motor from the wheels to enable free rolling. With BMW’s fifth-gen motors, that clutch is not necessary, as you can simply stop the generation of the magnetic field and just allow the car to coast.

BMW’s New Electric Motor: A Special Type of Brushed Motor

The fact that BMW chose to create brushed motors for its latest EVs is at odds with the direction the industry seems to be moving in. It is believed that the brushes not only wear out over time and will need to be replaced (an item of maintenance that doesn’t exist for brushless motors) but their contact with the copper commutator results in the creation of very fine dust.

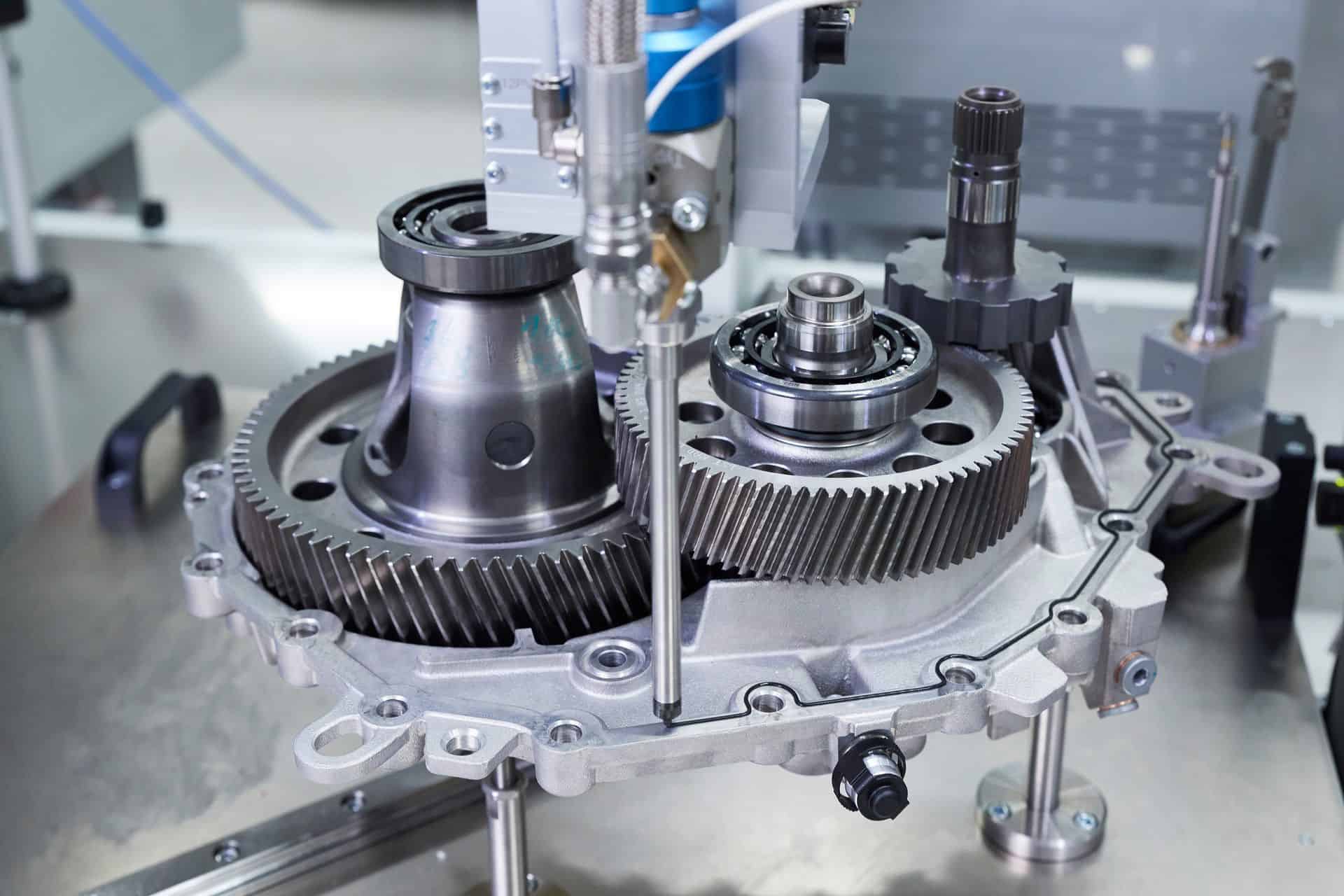

This dust is not only conductive, so it could create a dangerous connection, but it’s also considered a health hazard if inhaled. BMW says that it’s eliminated the problem by placing the brushes in a completely sealed space that doesn’t allow any particles to escape. Other parts are also prone to wear in this type of motor, such as the slip rings, which are a hugely important part of the unit that transfers power between the rotor and the stator.

BMW says it chose this type of motor because of the performance characteristics it can lend to vehicles. The big one is power density, which BMW said was improved by 30 percent over its fourth-generation motors, but the precise control over when the rotor was powered also allowed for improved efficiency.

BMW’s Fifth-Generation eDrive Powertrains Feature a New Type of Electric Motor

Even though energy recuperation through regenerative braking can help EVs be more efficient in stop-start traffic situations, at higher speeds, it’s often more efficient to just coast with as little resistance as possible. BMW’s fifth-gen motors allow for coasting without the need for a physical clutch, thus helping keep overall vehicle weight down and efficiency high.

Not having to rely on rare-earth magnets for these motors also makes their entire manufacturing process nicer to the environment. The most common rare earth elements used in electric motor manufacturing are neodymium and dysprosium, with the latter being considered especially scarce.

The problems with using these materials on a mass scale don’t just stem from their scarcity, but also because they mostly come from China, and this brings ecological, logistical, and geopolitical implications that many companies would just prefer to avoid. This puts those who become reliant on these metals at risk of fluctuating prices, geopolitical challenges, and environmental concerns that can’t be avoided given the limited number of sources and their location.

BMW’s decision to use this type of motor in its EVs is at odds with what most of the industry is doing these days. However, the fact that these motors can deliver a lot of performance and make EVs really quick is in keeping with BMW’s ethos as a manufacturer of premium, sporty vehicles that are fun to drive. The manufacturer wants to maintain this image as it transitions into the electric age, and these motors are one way it’s trying to do it.

Advantages of BMW’s EESM

If you’ve ever used launch control in one of BMW’s latest and most advanced EVs, like the iX1, i4, and i7, you will have noticed the entire car shaking just before launching itself toward the horizon. This is done by making the wheels quickly move back and forth, and it makes BMW’s EVs some of the most exciting to launch on the market; they’re even more exciting than some much more powerful EVs, specifically because they have the kind of physical feedback that battery-powered vehicles usually lack.

Combining the best features of both synchronous and asynchronous motors into a new type of motor, making it without the need for rare earths, and these motors’ ability to deliver strong acceleration and even vibrate their wheels before launching is what makes them special.

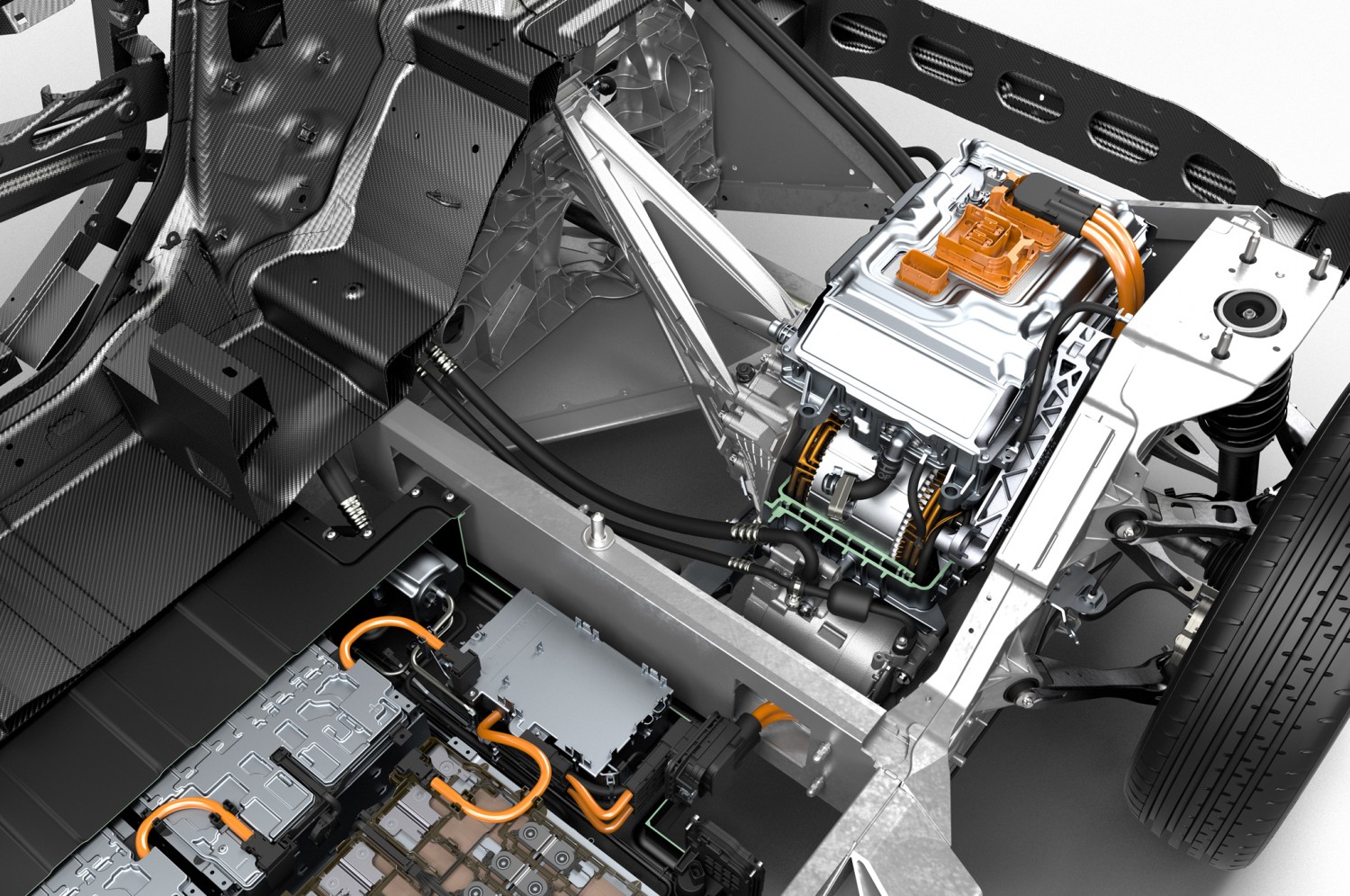

New Electric Motors Coming With Neue Klasse

It will be interesting to see if BMW will carry on using its special type of motor as part of the sixth-generation eDrive powertrains from its Neue Klasse line of models that debuts in 2024 or 2025. So far, the manufacturer has stayed tight-lipped on the matter, only revealing that the motors in its Neue Klasse EVs will be more compact than what it’s using today.

The most exciting application for these electric motors will be BMW’s future fully-fledged Motorsport EVs. We already know the manufacturer is planning to launch electric M models, even ones with a quad-motor setup, and they could arrive by 2027. Just like with the brand’s much-loved straight-six, V8, and V10 engines, the electric motors will be an integral part of the driving experience, and they will need to make the car feel not only blisteringly quick but also exciting to drive.