BMW announced the opening of a new Competence Center for e-Drive production today. Located in Dingolfing, at BMW Group’s largest European manufacturing location, the new center will allow the production of 500,000 e-Drive modules per year. Today, BMW’s CEO, Oliver Zipse and the Bavarian Minister-President Markus Söder symbolically launched production at the new facility.

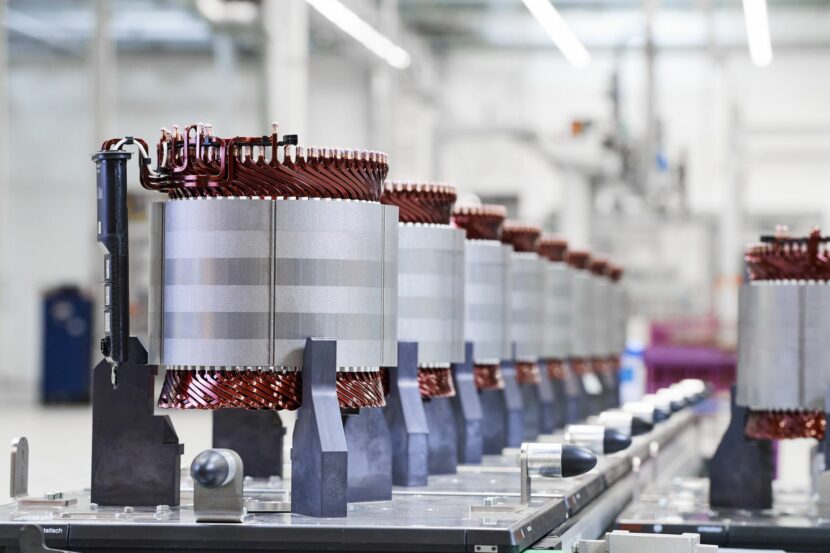

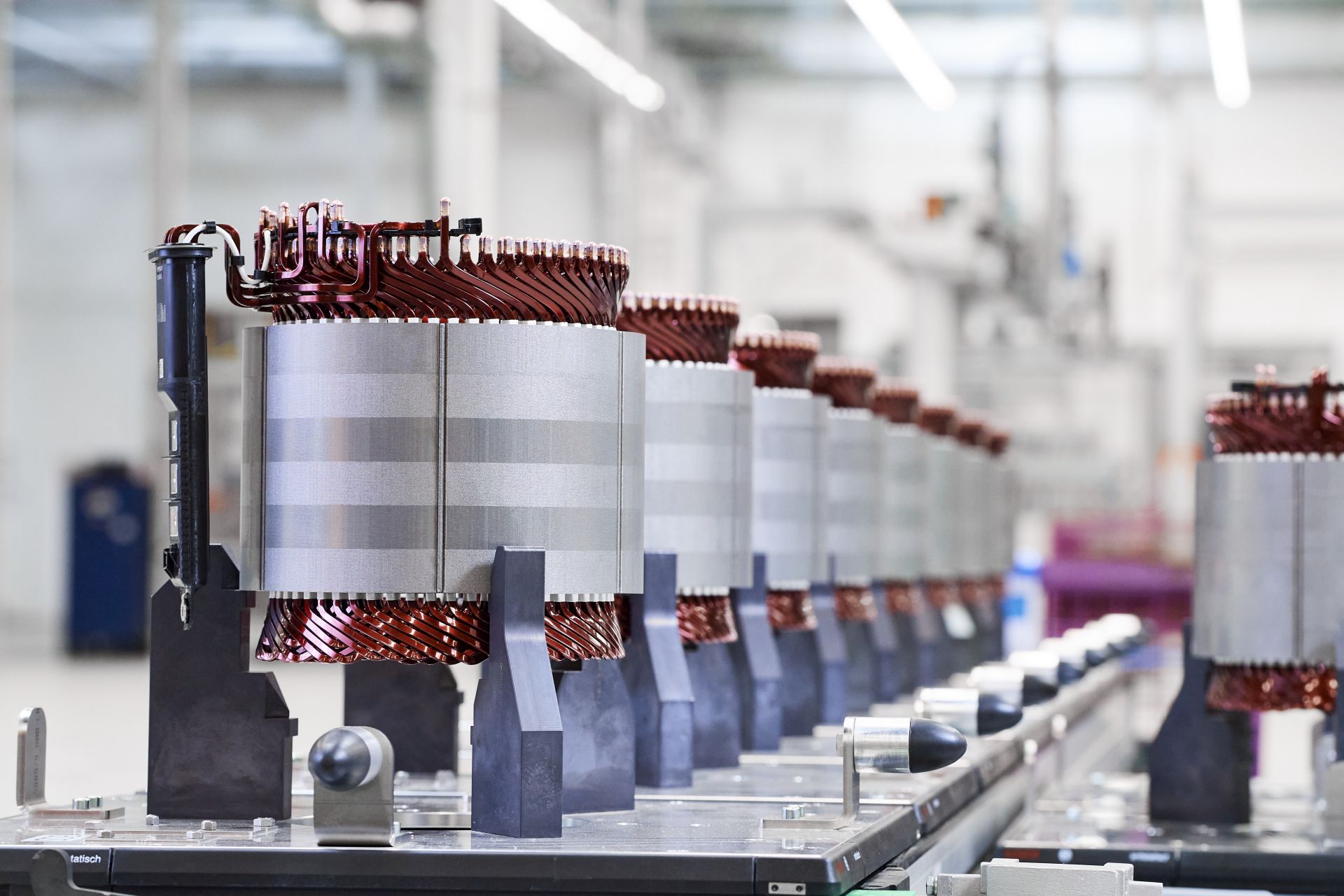

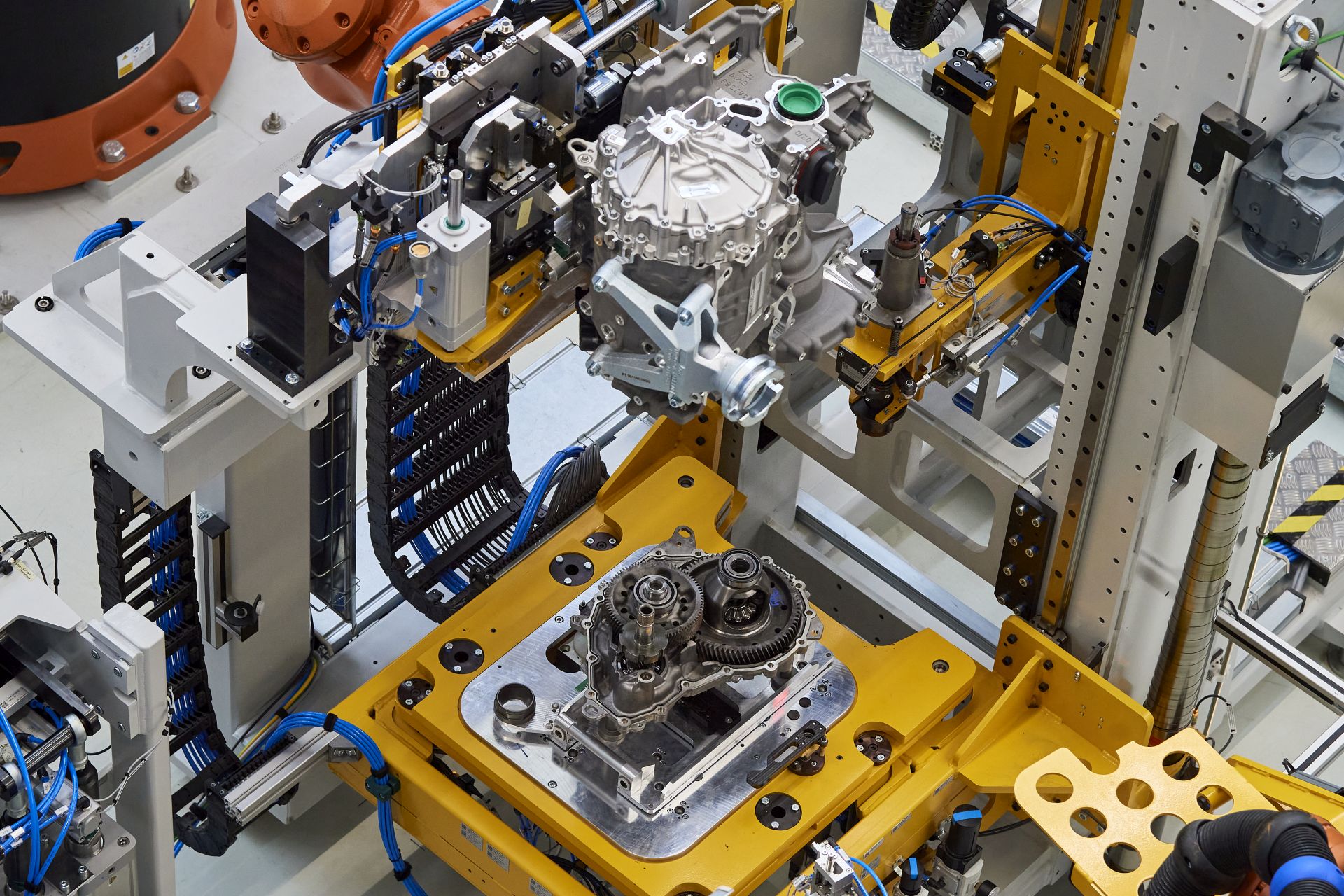

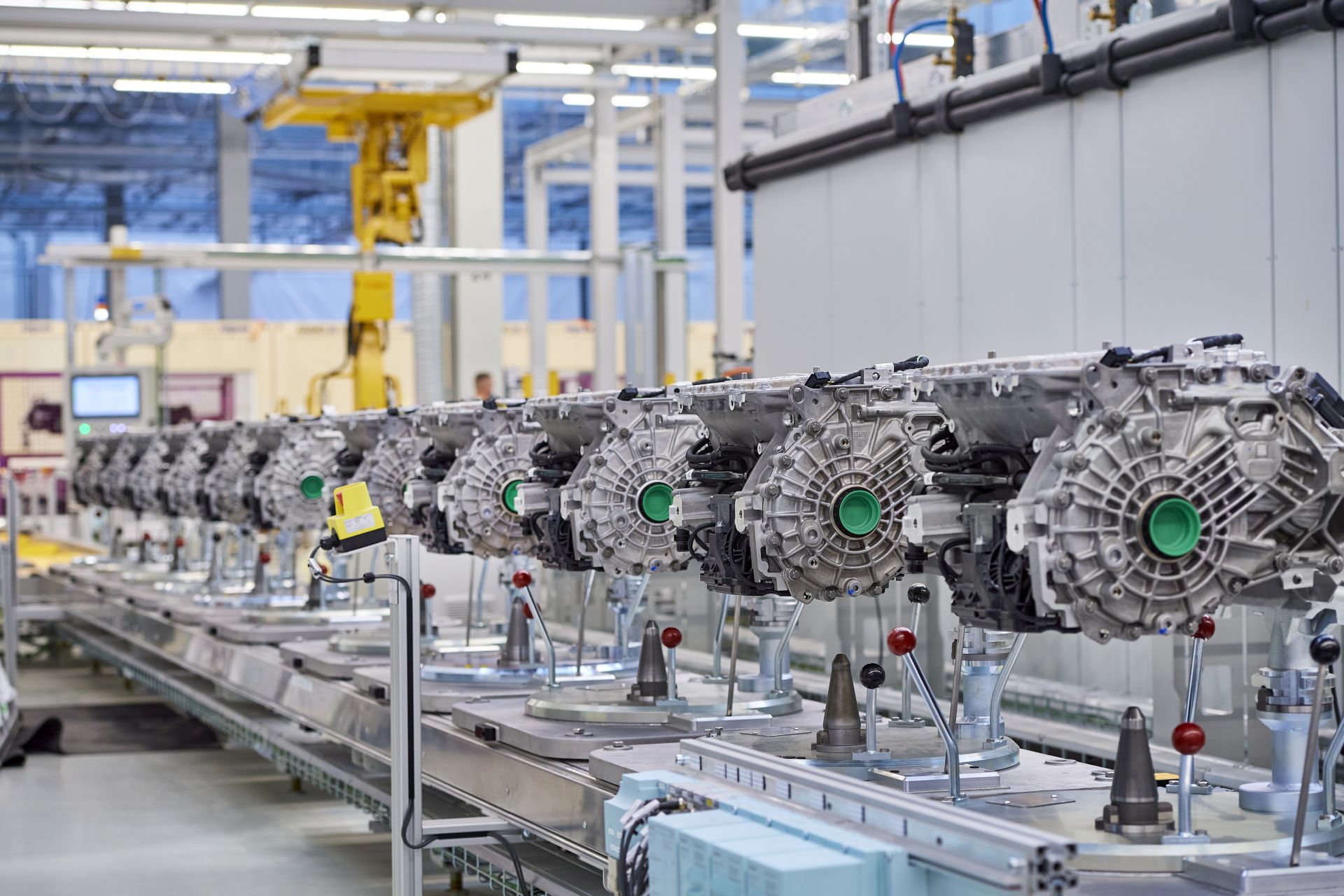

BMW has been making e-Drive modules since 2013, when the first electric car made by the Bavarian company entered production. The e-Drive module combines the electric motor, transmission and power electronics in a single, central housing.

These modules have been upgraded over time, as technology progressed and they are now entering the fifth generation. The new ones are to be used on the BMW iX3 for the first time, the new EV SUV being scheduled for production later this year, in China.

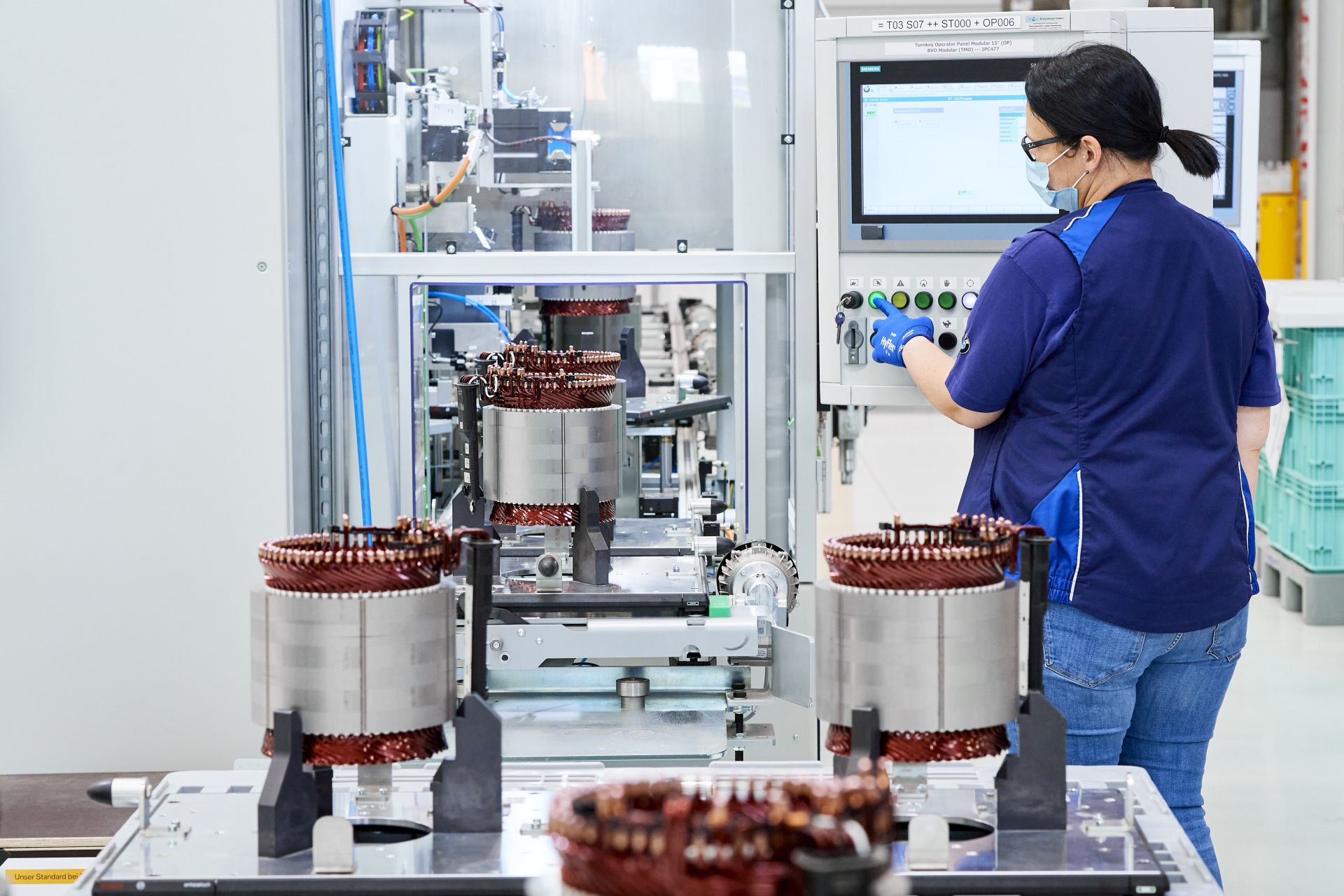

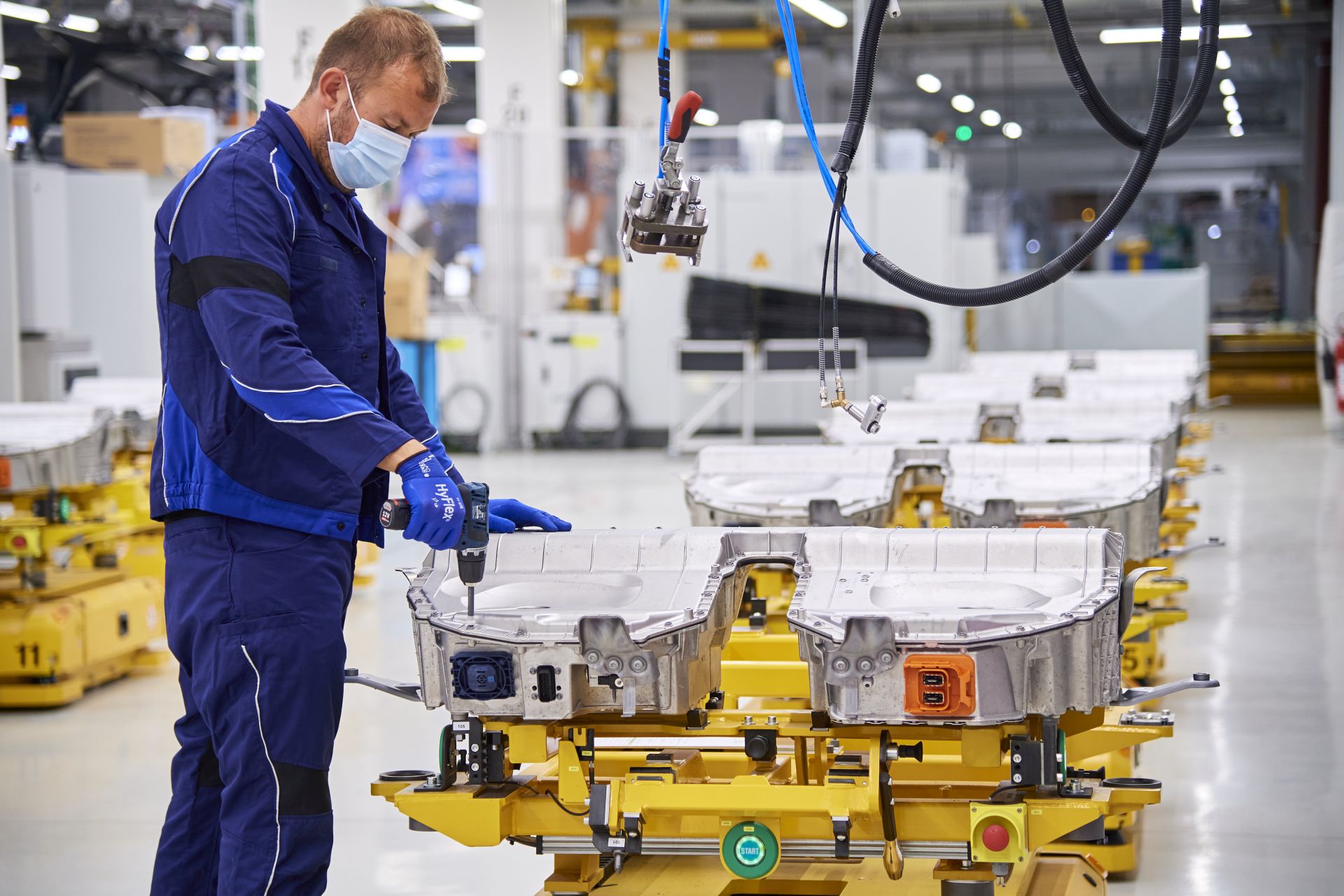

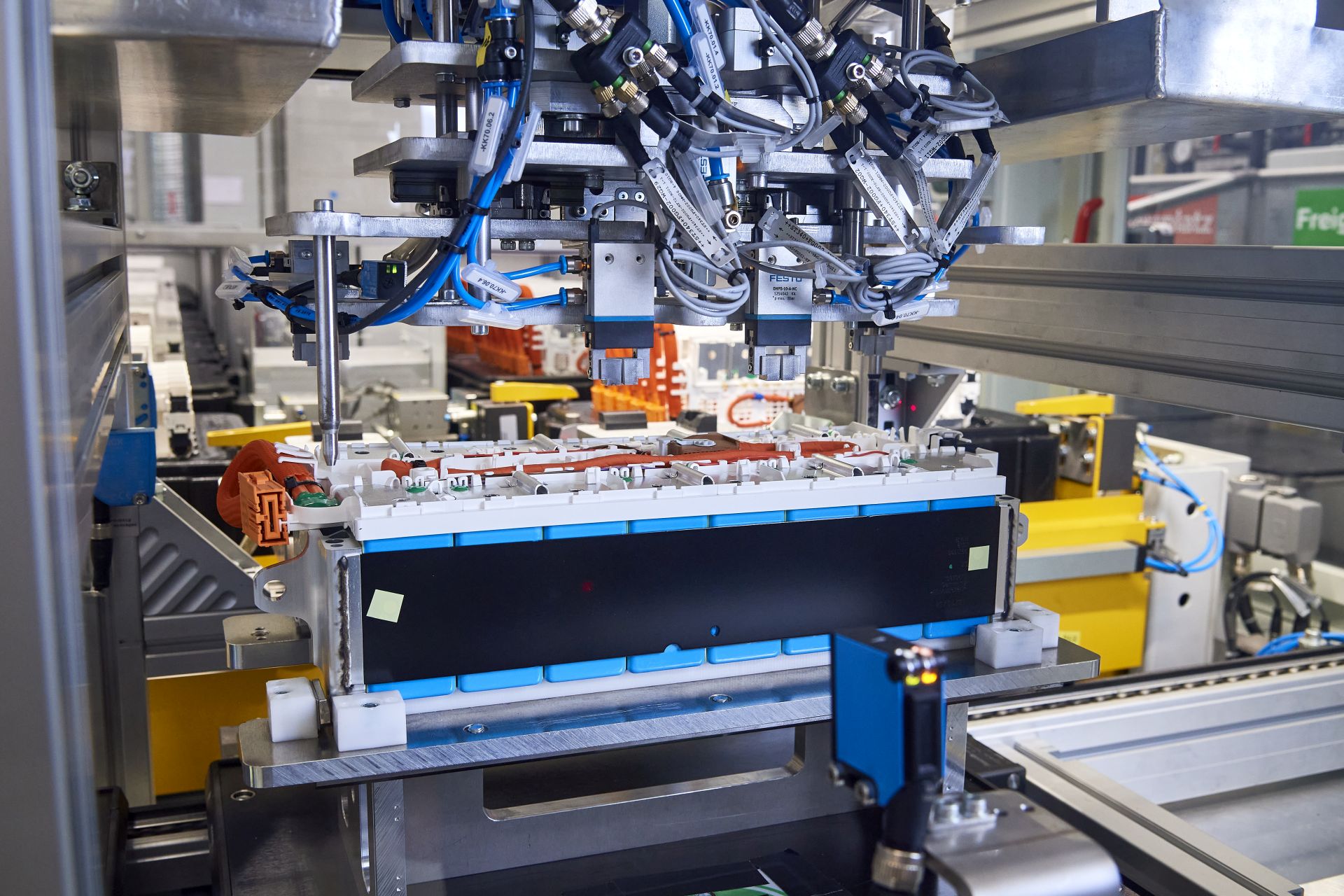

The new Competence Center in Dingolfing will produce electric powertrain components such as battery modules, high-voltage batteries and electric motors on eight production lines. Over the coming years, the company will set up four additional lines, which will boost the location’s production capacity significantly. Up to 2,000 employees will be working here once the location reaches full capacity, in a facility that spans over 80,000 square meters.

“We continue to ramp up electromobility and set standards for the transformation of our industry. By 2022, in Dingolfing alone, we will be able to produce e-drives for more than half a million electrified vehicles per year. At the same time, we will produce a mix of fully-electric vehicles, plug-in hybrids and models with a combustion engine on a single line, as required by demand, so we can offer our customers the ‘Power of Choice’. This shows how we have paved the way for making the shift in our industry a real success story,” said Zipse at the ceremony.

“BMW Group Plant Dingolfing is a perfect example of how the automotive industry is transforming itself for e-mobility. We have everything under one roof here: production of batteries, electric motors and electrified vehicles,” explained Christoph Schröder, head of BMW Group Plant Dingolfing.

This plant has years of expertise building components for electric vehicles. Series-produced high-voltage batteries for the BMW i3 have been coming off the line here since 2013. This location has also produced electric motors since 2015.