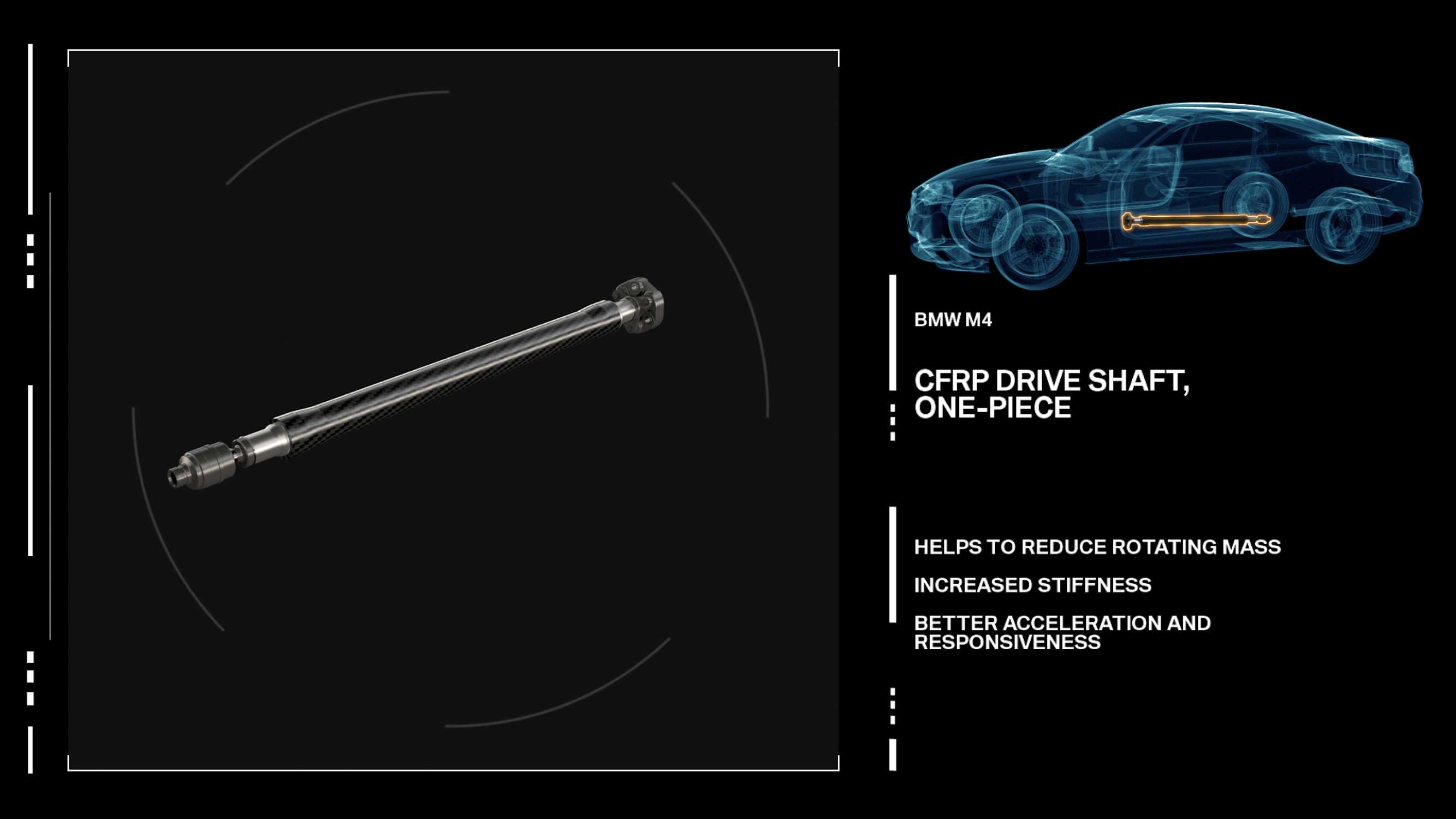

From November 2017 onwards, the CFRP driveshaft in the BMW M3 Sedan, BMW M4 Coupe and BMW M4 Convertible will be gradually replaced by an M specific driveshaft made of steel. BMW says this measure will create the necessary technical basis for meeting future statutory emissions requirements. At a later point in time, a petrol particulate filter (PPF) will be incorporated into the existing installation space in these models in major markets.

“The newly developed steel driveshaft has been designed to ensure the superlative performance and handling qualities of the BMW M3/M4 high-performance sports cars remain unaffected,” BMW says in a press release.

For production-related reasons, this pre-enabling needs to be carried out universally for the BMW M3 Sedan, BMW M4 Coupe and BMW M4 Convertible. This measure does not apply to the BMW M4 CS and BMW M4 GTS special-edition models.