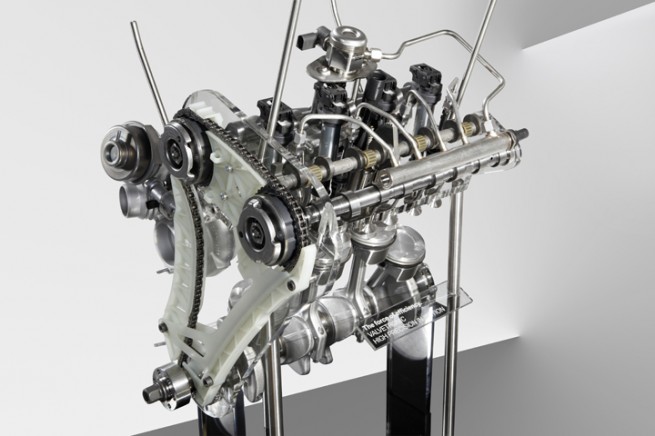

Munich, Germany – BMW discussed the new 500cc per cylinder engine architecture that will serve as a building block for upcoming three, four, and in-line six cylinder gasoline and diesel engines. This common cylinder architecture allows for significant shared componentry. It accounts for 60% shared components among gasoline variants and a like percentage among diesel variants, with 40% commonality between the diesel and gasoline variants.

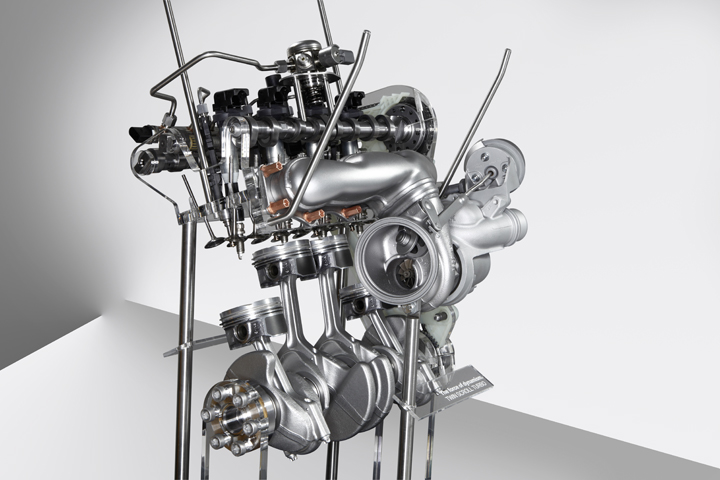

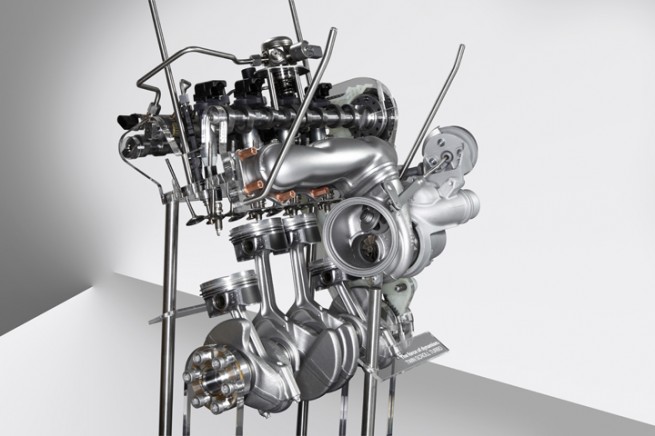

On the gasoline side of the family are cylinder heads that incorporate BMW’s ‘TwinPower’ attributes. TwinPower refers to variable valve timing and lift (VANOS and Valvetronic) combined with Direct Injection. TwinPower is enhanced by turbocharging, with either a single turbo (3 cylinder), TwinScroll (four and six cylinder gas engines), or dual turbochargers for diesel variants.

The direct injectors for the gasoline engines are of the solenoid variety and are not capable of stratified charge. The N54B30 engine uses piezo direct injectors, but the N55B30 uses solenoid injectors. The N55 cylinder head architecture (VANOS, Valvetronic, and solenoid direct injectors) may, in some sense, be considered the direct antecedent of the cylinder head architecture of the new engine family.

But the commonality of bore spacing, cylinder head bolt location, and bore and stroke allow for significant production process savings. The engines will be produced in Munich, Germany and Steyr, Austria. Because of the common architecture the assembly lines can mix and match both diesel and gasoline engine variants on the same line (within some constraints) in order to meet demand. It will significantly reduce idle time in those facilities.

The output per cylinder is projected to be in the 40 to 65 HP for the gas engines, and 27 to 54 HP for the diesel engines, torque will range from 44 lb-ft to 74 lb-ft for the gas engines and 55 lb-ft to 74 lb-ft for the diesel engines. The specifics of power will be determined by the particular role the engine is called on to perform. Base engines and engines used in hybrids will be on the lower end of the range and performance engines will occupy the upper reaches of the performance range.

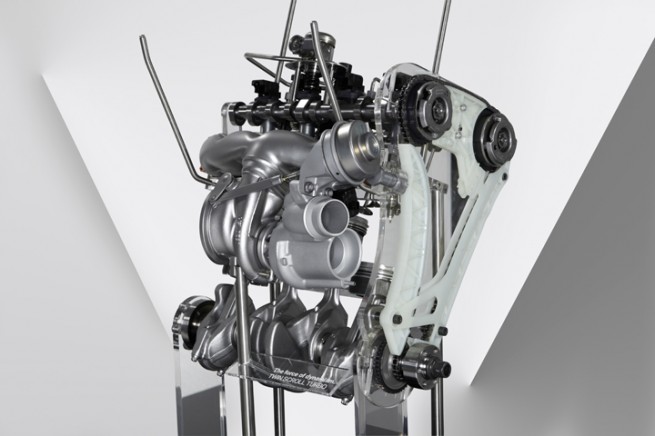

In addition to longitudinal mounting for all engine variants, the three and four cylinder variants can be mounted transversely. Adapting the common architecture (with common cold and hot sides) allows for a 50% reduction in variations of engine/vehicle interfaces (radiators, air intake, exhaust routing, engine mounts, and climate control). That also translates into reduced production costs.

Left unspoken during the presentation, but raised as a question is, what is the fate of the 8 and 12 cylinder engines. They live on (and are necessary) but are not a part of this engine family. For one thing, the V configuration complicates adding them into a common assembly line for the inline engines. And the 3,4, and 6 inline engines will be in the bulk of the products BMW produces, with, I believe, the V8 and V12 playing an increasingly ‘niche’ role. After all the focus is to provide high specific power on demand, with frugal operating characteristics under most driving conditions. It is the only good way to meet ever more stringent fuel economy and emissions targets imposed by governments.

Two additional tidbits of note, BMW was asked if a two cylinder was possible, and it is, but not currently under consideration. And turbocharging is not a must – a naturally aspirated variant of the

engine family may be considered for certain niche applications, although the specific use of VANOS, Valvetronic, and direct injection favor theuse of turbocharging.

The video that BMW provides to illustrate the new engine family is a bit to cute for my taste, but it did illicit a few “aha’s!” from the assembled journalists when the engine is shown being rotated to fit a transverse mount.

Download the PDF presentation on BMW’s EfficientDynamics Engine Family