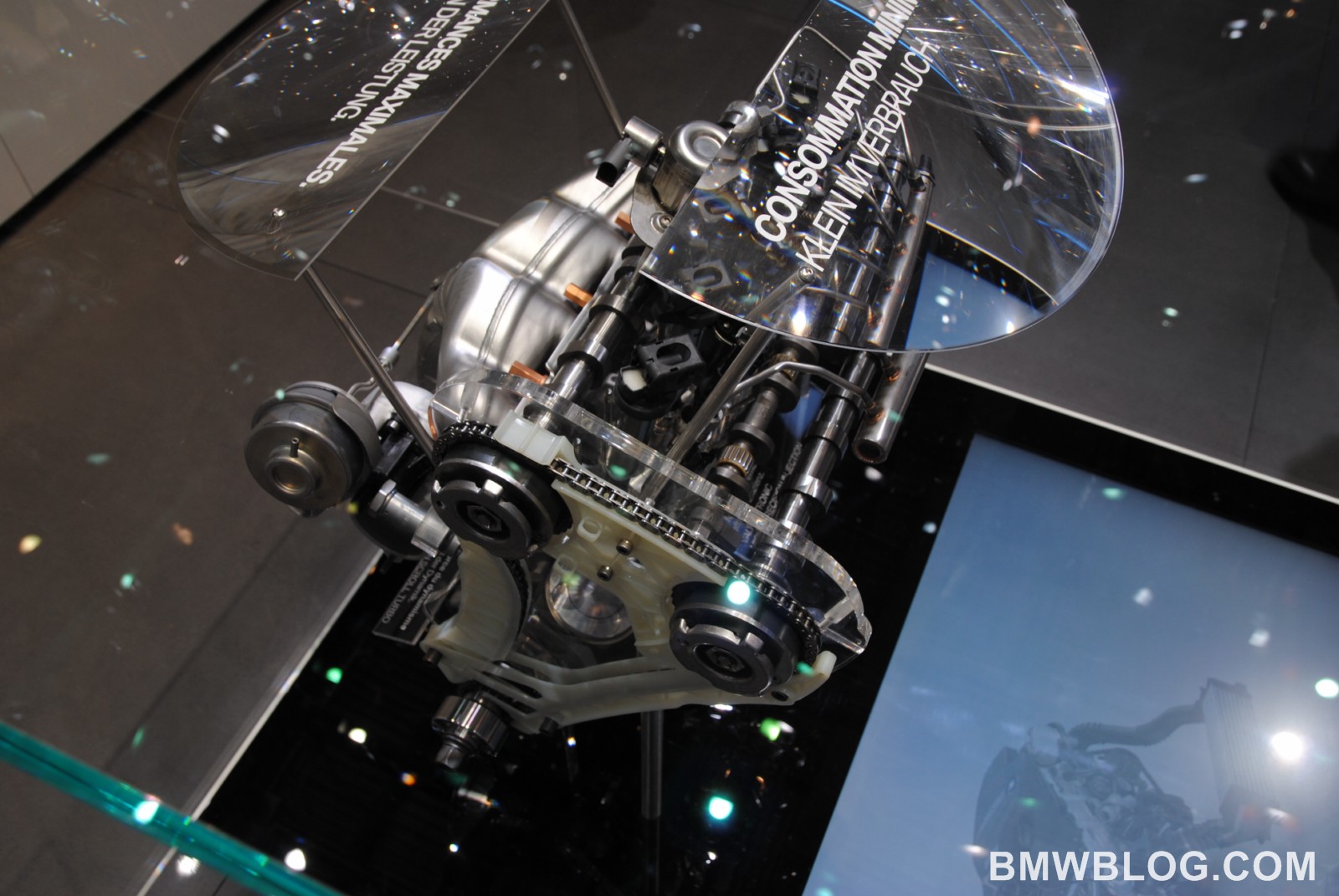

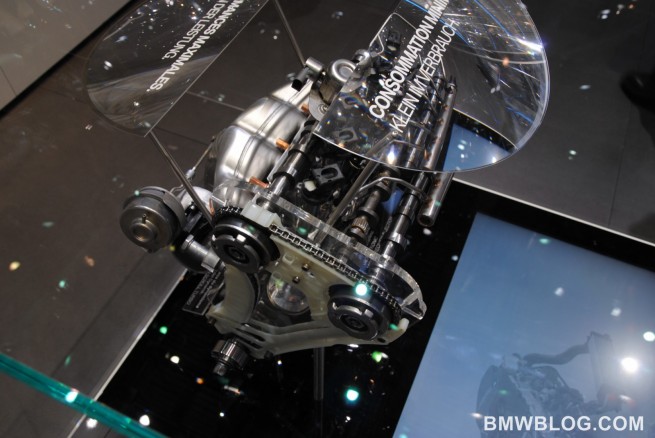

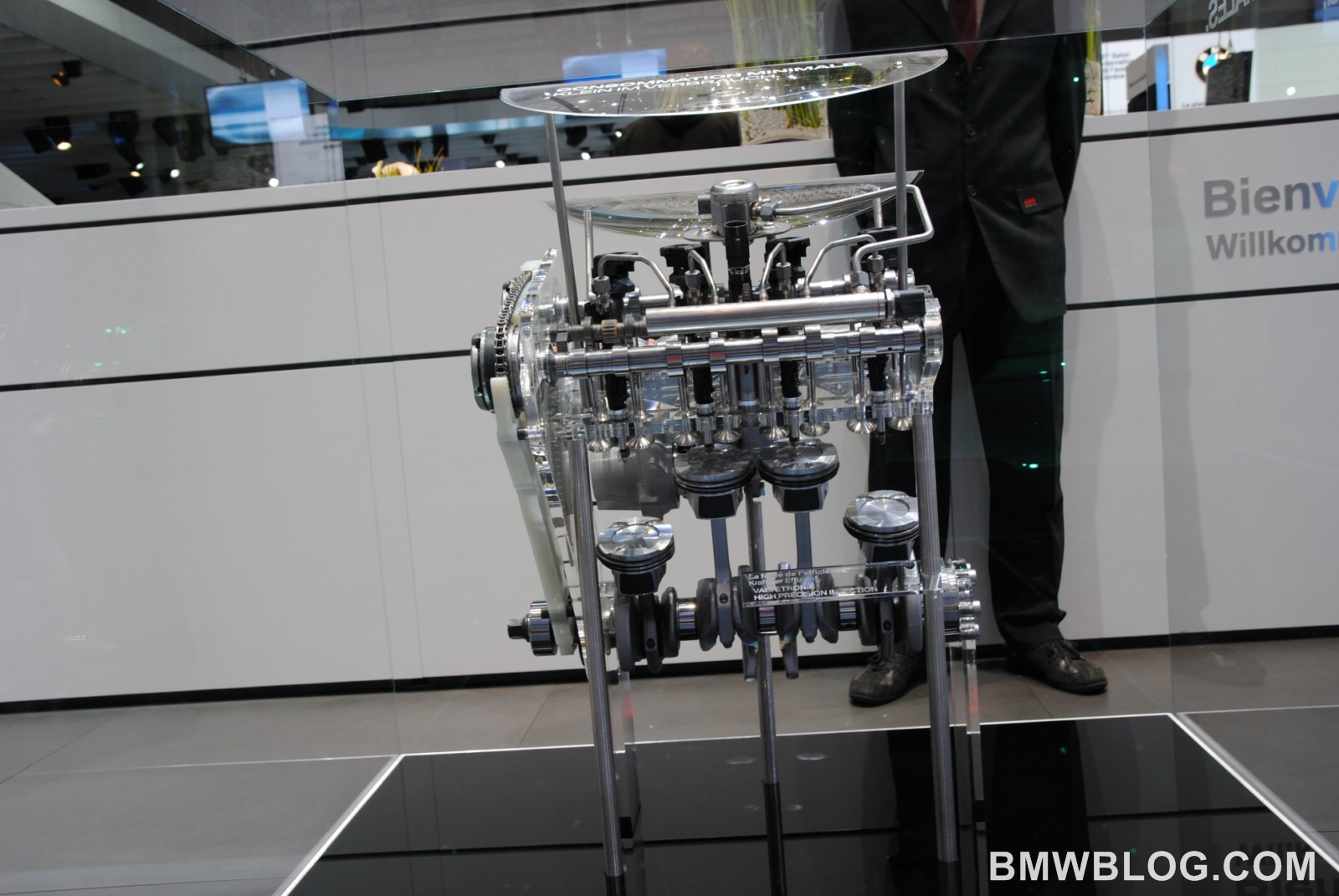

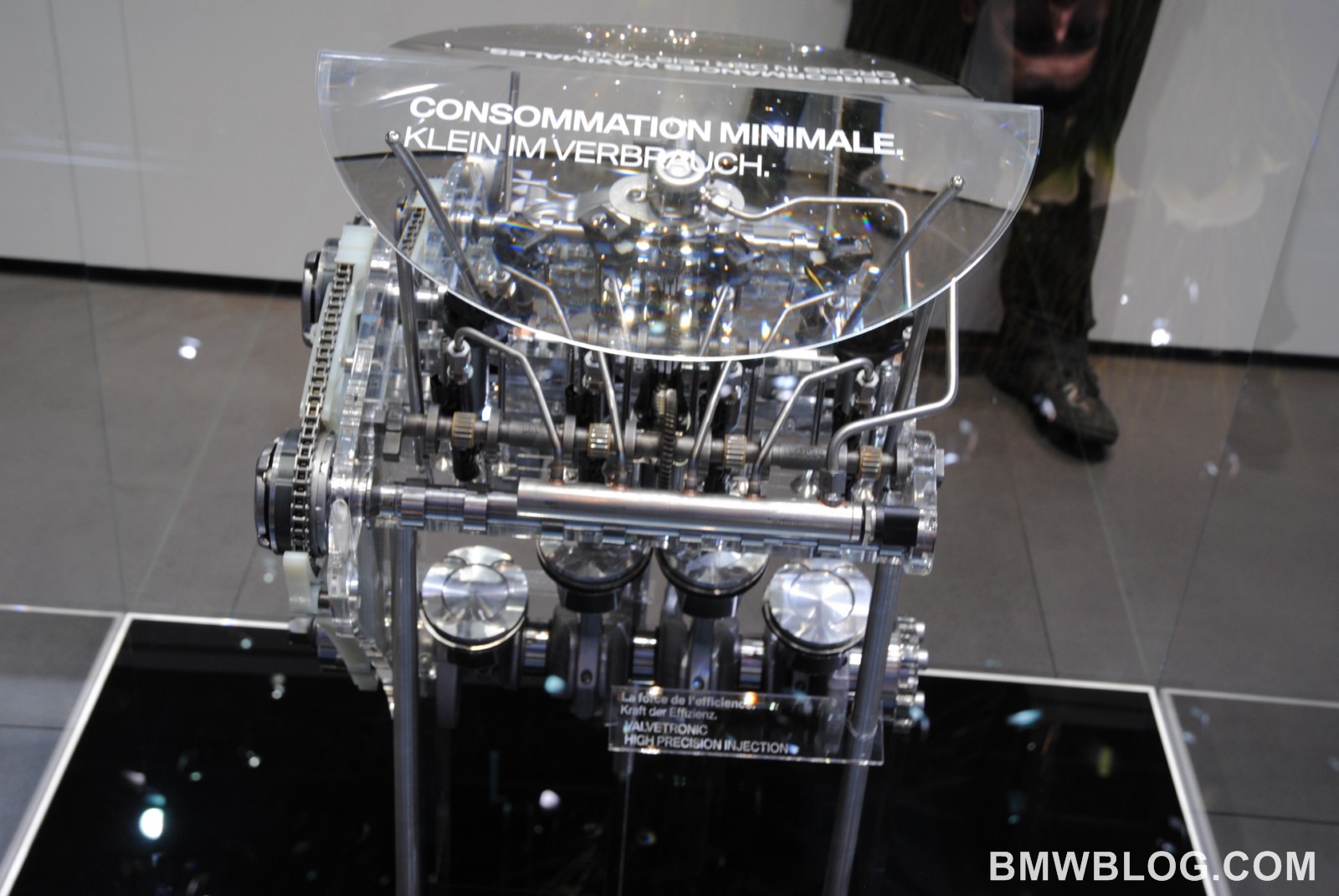

Four-cylinder turbocharged engines will account as an important piece in the overall future strategy for BMW. The importance of the new N20 four-cylinder turbocharged engine was revealed at the 2011 Geneva Motor Show when Dr. Klaus Draeger, R&D chief, opened the BMW press conference with a speech on the new four-cylinder engine.

In the future, BMW will make extensive use of the different four-cylinder turbo engines in various models, from the 1 Series to the 3 Series, and some X-models. The first step in their EfficientDynamics strategy around four-cylinder bangers starts with the BMW X1 xDrive28i, the first model to receive the recently unveiled N20B20 four-cylinder engine that delivers 245 horsepower, offering similar performance as the six-cylinder aspirated engine but with significantly lower fuel consumption.

To learn more about the engine, we sat down with Dr. Bernardo Lopez-Alvaredo, Head of Drivetrain Evaluation.

BMWBLOG: Why the shift from six-cylinder naturally aspirated engine to a new four-cylinder turbo?

BMWBLOG: Why the shift from six-cylinder naturally aspirated engine to a new four-cylinder turbo?

Dr. Lopez: We see ourselves as part of the overall EfficientDynamics strategy and engine development is one portion that contributes to it. In the last years, the six-cylinder turbocharged won several awards and the new four-cylinder engine is the little brother of this powerplant. In a way this is the extension of this technology that was first proven in the N55 six-cylinder twin-scroll turbocharger.

BMWBLOG: Why the change from N54 twin-turbo to N55 twin-scroll which is the base for the new N20 four-cylinder?

Dr. Lopez: The system here is in a way more efficient, because you have basically the same functions, you separate the exhaust from two pair of cylinders and introduce into the turbocharged system. Of course, we reduced the volume you need, so it has a lot of advantages, less weight, less parts.

BMWBLOG: What is biggest challenge in designing this engine?

Dr. Lopez: Our aim is to satisfy customer that have been used to the six-cylinder engine, so for us the big goal in engineering was to deliver even better performance with lower fuel consumption, while delivering the same level of quality. The technology components are already known from the six-cylinder, so some were modified for the four-cylinder. The decoupling of vibrations was a new part that we had to design for the four-cylinder.

BMWBLOG: Is this the first use of Valvetronic, Vanos, and direct injection in a BMW 4 cylinder?

Dr. Lopez: The Valvetronic was first introduced in 2011 in a four cylinder engine. The Valvetronic has two functions here: one, to lower the fuel consumption, a function we already had in the four-cylinder naturally aspirated engine. Typically you work against the throttle, so you lose efficiency there. Basically what you do is completely open the throttle, but then you need a way to regulate the amount of air that goes into cylinder, so we introduce the Valvetronic so the valves detect the height. when they open fully you get the full mode, when they open a tiny bit, you’re in idling speed. The cylinders don’t works against the pressure difference that is build up by the throttle. It’s an efficiency measure that we had starting in 2001 and developed the system further over the years, and now in the turbo system what it is interesting is that it not only delivers an efficiency component, but a performance component as well. If you use a turbo engine in a system without Valvetronic you have to wait until the amount of air has gone from the throttle to the intake of the engine. With the Valvetronic you can regulate it very close to the engine, so you have a better response.

BMWBLOG: Compared to the six-cylinder engine, is there a difference in turbo lag?

Dr. Lopez: The goals we received as the powertrain unit was that this engine should have no turbo lag at all and I believe we have done a pretty good job with that ask. From our point view, you do not notice any lag due to some of the things I previously outlined.

BMWBLOG: Would you say that the twin-scroll has a longer lifespan than the twin-turbo? We have seen many issues in the past with the N54 powerplant.

Dr. Lopez: We did look at the whole package. If we have two independent turbo systems, of course you potentially have more issues, then you also need more space in the car, more parts and in the end it would have lower efficiency. If you make it possible to penalize the whole exhaust energy without any loses to the turbocharger, you get better efficiency. From an engineering point of view, if you can do it with a single turbocharge, it’s better, however you have to take into account that the cylinders interact with each other, therefore twin-scroll. In a way, this is the perfect solution.

BMWBLOG: Has BMW tried to tune up this engine to see its full potential?

Dr. Lopez: The specific power of this engine is 90kW per liter which is already quite high. When we are looking at the overall properties, lifetime for example, when you raise it too high up you might get problems with the response or at least you have to do about the intake system. Of course, turbo systems can always be charged with more but then you have certain risks of the turbo lag which you have to compensate with additional measures that also add other “costs”.

Some questions were further asked by our sister-magazine BimmerToday.de

BimmerToday: Was there a particular attention paid to the engine sound?

Dr. Lopez: Yes. It is of course true that four-cylinder engines have a different sound, and you have to take special measures here. We have a different arrangement of the balance shafts, which leads to less vibration. Then we have the dual mass flywheel and a centrifugal pendulum installed, so vibrations from the engine can be “erased”. In sum, we get over the whole speed range with an acoustic vibration behavior similar to that of the six-cylinder, in some places even superior to.