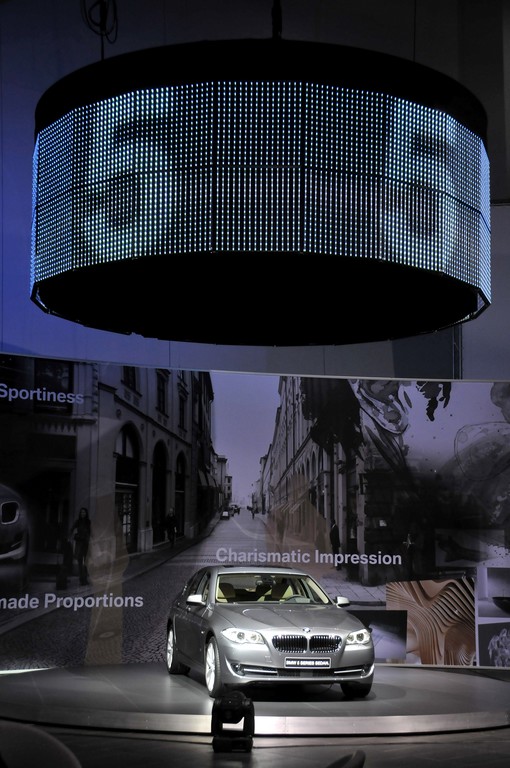

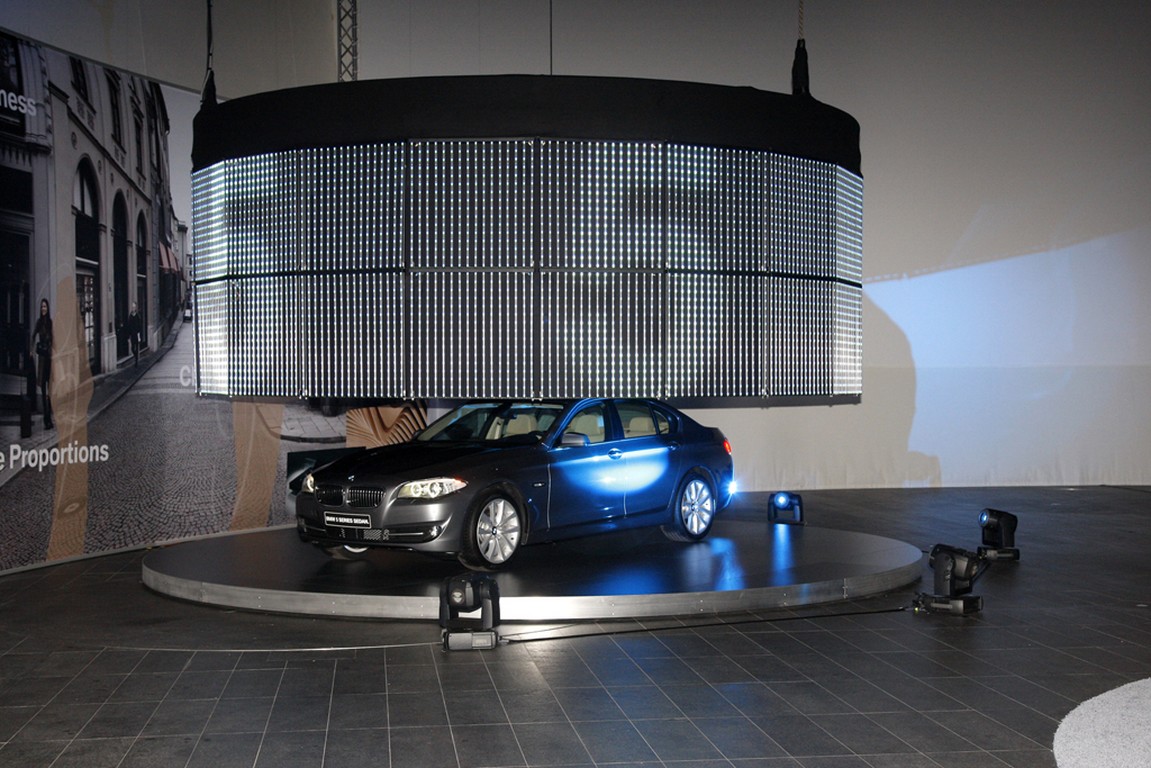

Many of you have always been interested in finding out more about BMW’s design process, the steps taken before the final product is being developed. At the BMW 5 Series world premiere, BMW shared some information on the process of creating a new model.

From the original idea through the first draft to the final model.

The process of creating a new model covers a period of several years, starting with the determination of the vehicle’s concept and the formation of the Project Team. From then on all departments and functions work together closely in achieving the targets defined for the respective model, focusing consistently on all technical components and the design of the vehicle which, in accordance with the design philosophy of the BMW Group, must render the specific values of the product and its substance accurately and authentically in and through aesthetically convincing design language.

The fundamental features of the Package Plan are determined right from the start at the beginning of the project phase, generally some five years prior to the planned start of production of the new model. At the same time the designers create the first scale models and renderings of the new vehicle.

Such determination of the vehicle’s proportions is of great significance within the design process. Like every product, an automobile must have ideal proportions as the key to aesthetic design and harmonious looks. Since the human being has a well-honed and very natural feeling for proportions, this feeling is crucial to the first impression of any new car.

Such determination of the vehicle’s proportions is of great significance within the design process. Like every product, an automobile must have ideal proportions as the key to aesthetic design and harmonious looks. Since the human being has a well-honed and very natural feeling for proportions, this feeling is crucial to the first impression of any new car.

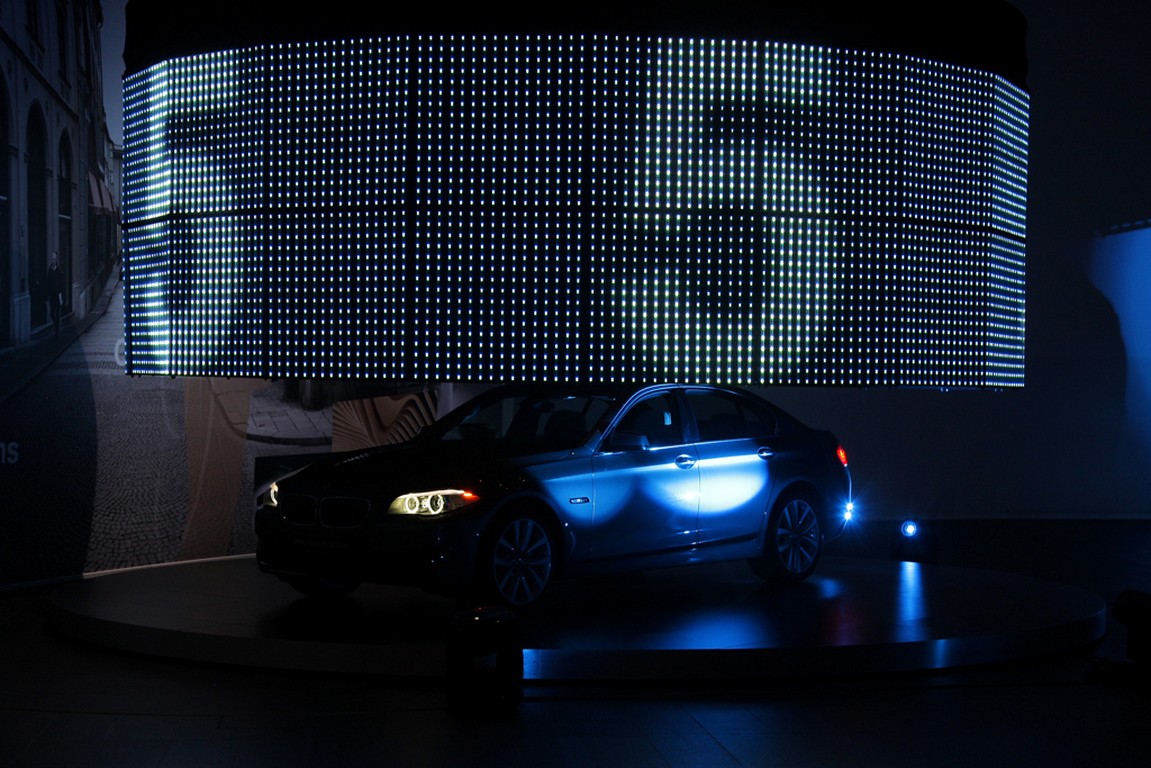

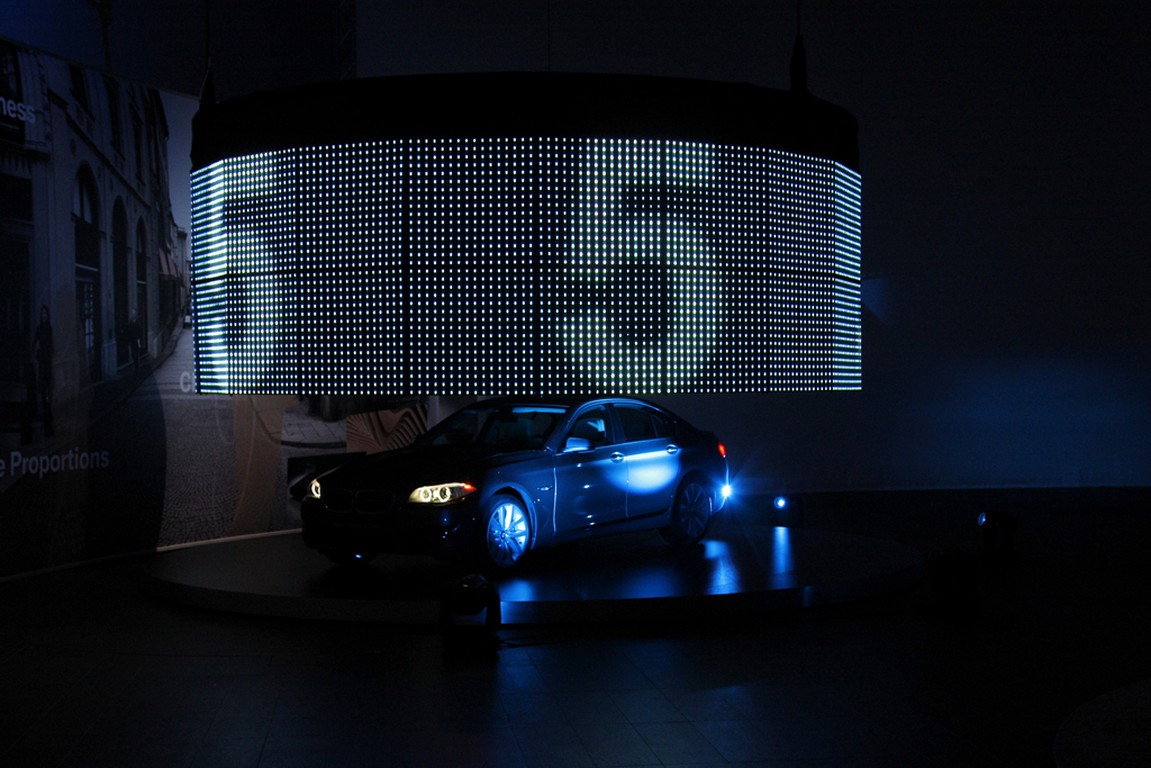

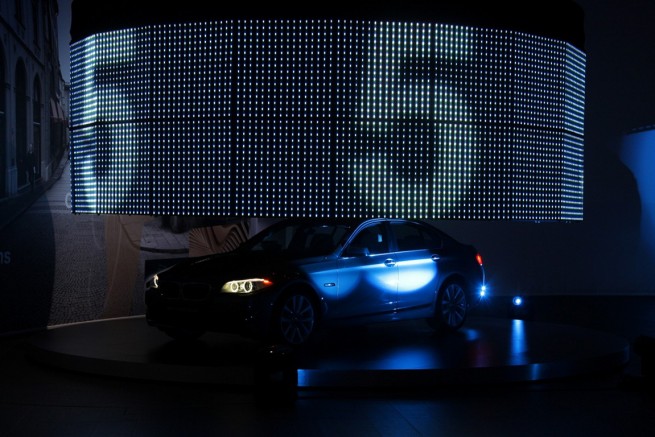

With this in mind, well-balanced proportions were given high priority in the process of designing the new BMW 5 Series Sedan. The coupe-like silhouette, smoothly flowing roofline, the long wheelbase, the short overhang at the front and the long hood give the car a graceful and athletic look. Enhanced by the powerful shoulders and the wide rear stance, these proportions confirm the sporting character of the BMW 5 Series Sedan.

The design process is split up into three phases to be completed by each vehicle during its development in BMW Group Design. Within the Company, these design phases are referred to as Understanding, Believing, and Seeing.

The first phase seeks to create a joint understanding of all contributing factors and their impact on the design proposed. Essential features of the Package Plan such as the wheelbase, luggage compartment capacity, the range of engines, interior width and safety requirements are already known at this point as the original parameters and general input for the design process. Hence, the convergence of design and technology requires considerable integration and networking right from the start even at this point. In the end,

all of the technical innovations available are to be implemented in a manner perceived by the user as perfect in their functions, meaningful and, at the same time, beautiful to behold.

Internal contest as the starting point in designing the new BMW 5 Series Sedan.

An internal contest in designing the exterior and interior is one of the most important highlights in the process of BMW Group Design. The designers compete with one another in a highly creative contest, finally presenting their personal drafts and designs. Under the guidance of the responsible Head of BMW Group Design, the Exterior and Interior Design Teams developed all kinds of different ideas from the start in the process of designing the new BMW 5 Series Sedan, using sketches, virtual renderings, and clay models.

Proceeding from the proportions of the new vehicle, which are already determined in advance, the task in the next phase is to create the characteristic design language of the respective vehicle. In this case input comes from innovative design drafts and the objective of offering an excellent aesthetic balance of proportions and surfaces.

In developing the new BMW 5 Series Sedan, the designers and model builders worked together in this phase to create full-size models following precisely these criteria. Very few car makers attach such great attention to full-sized models made of clay as a special material used by the designer and refined to even the smallest detail.

Covered by a special surface film very similar to body paintwork in Titanium Silver Metallic, each clay model enables the viewer to realistically judge its lines, surfaces and proportions under all kinds of light conditions.

Another advantage to clay models is that provide the option to consistently enhance and develop the original design draft, each modification being implemented directly on the full-size model and thus made visible quickly and realistically.

The number of clay models is reduced step-by-step in the “Believing” phase through decisions taken by the Board of Management. During this phase the designers form a firm consensus of the perfect exterior and interior of the new model, the way they see the ideal result. The final decision on the final design is taken some three years prior to the start of production in a final round of scrutiny wherein the last two variants are compared.

In the ensuing “Seeing” phase of design development, both the exterior and interior design are presented in their final form, with careful refinements down to the smallest details. Here again, all demands and requirements are coordinated with utmost care through close interaction with the other departments in the convergence of design and technology.

Further coordination down to hundredths of a millimeter is ensured through ongoing exchanges between designers, engineers and production specialists. Everyone seeks to give the final product a premium standard from the quality of its surfaces all the way to each micro-feature. Extreme precision is of utmost significance in this phase, since even the slightest inaccuracy would be rendered and multiplied hundreds of thousands of times on the actual production model.

The sculpture which has been perfected by human skill is translated into a product reproducible by machines only after all of this has been done. The design model is converted through CAD using laser scanning into a three-dimensional feasibility model providing the technical reference point for all further developments.

Perfect agreement of craftsmanship and virtual development.

The chosen design is implemented in the process of series development by careful interaction of computer-based renderings and presentations and equally painstaking work on the clay model. This reflects the core philosophy of BMW Group Design, seeing the human being as the central factor in creating emotionally powerful design. Virtual methods are applied in parallel to optimize both the efficiency of the development process and the precision of design and construction assurance.

Rapid prototyping is another option in creating the fundamental parameters required for a meaningful decision-making process. Proceeding from the data defined by the computer, design specialists are able to build three-dimensional models of individual components, enabling them to assess the dimensions, ergonomics or geometry of the vehicle at an early point.

The combination of skilled craftsmanship and virtual development is further refined by years of experience in each development project, making ever-greater use of the respective methods and their potentials.