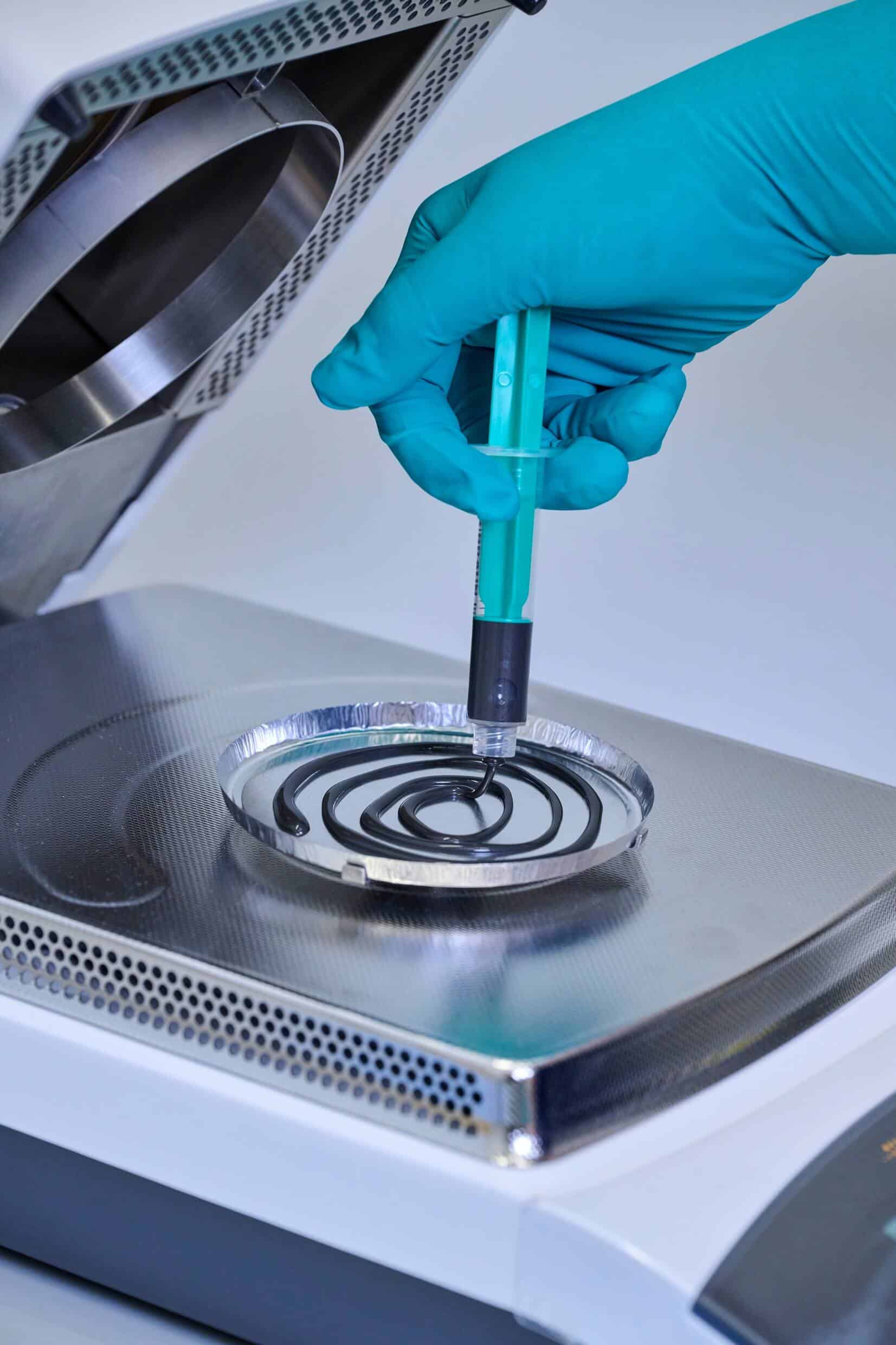

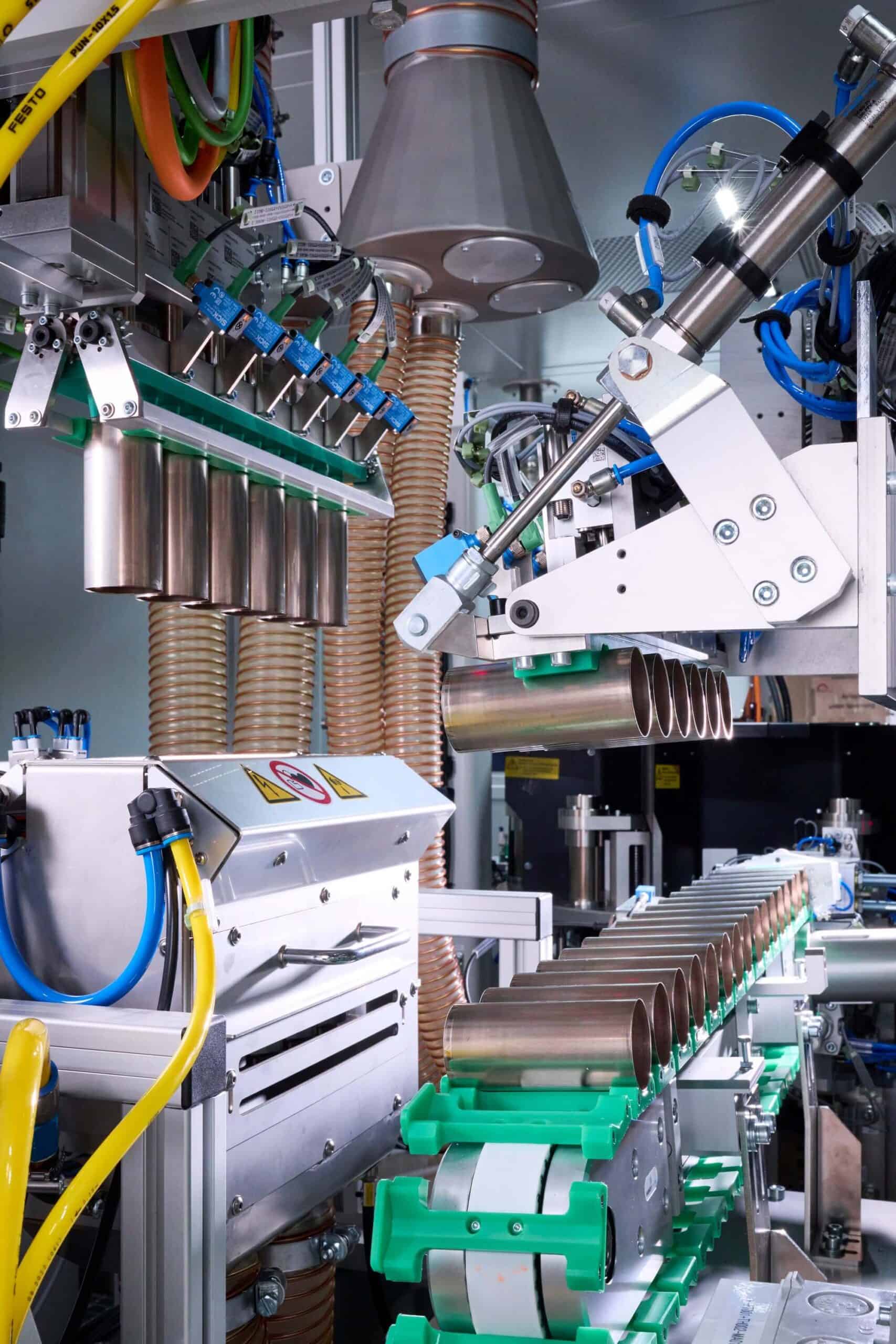

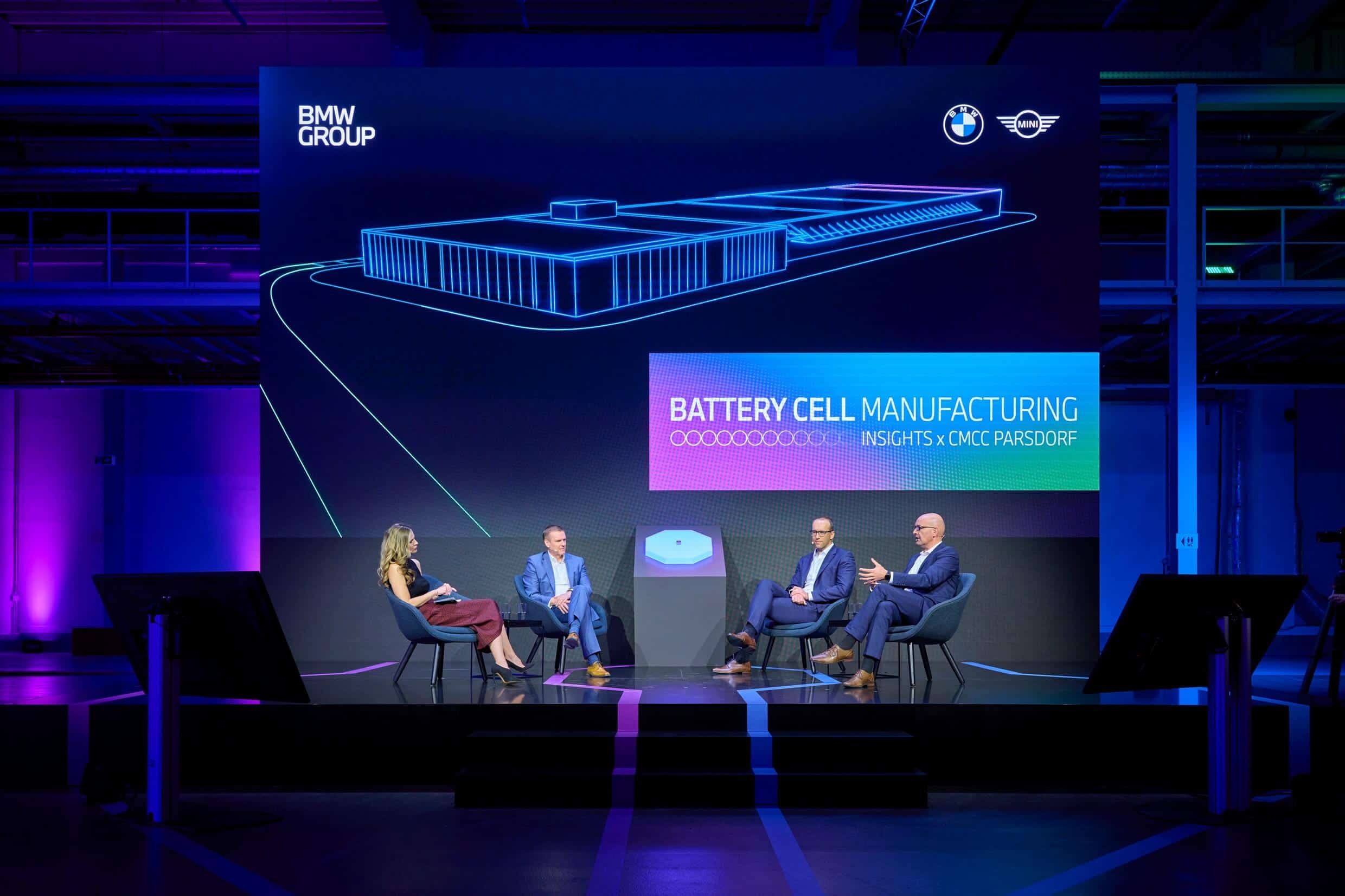

Production of next-generation EVs on the Neue Klasse platform will get going in 2025 at the new Debrecen factory in Hungary. Meanwhile, BMW is paving the way for its Gen6 battery technology by producing round battery cell samples at its new Cell Manufacturing Competence Centre (CMCC) in Parsdorf, Germany. Approximately 80 people are employed at the site spanning 15,000 square meters, following an investment of around €170 million.

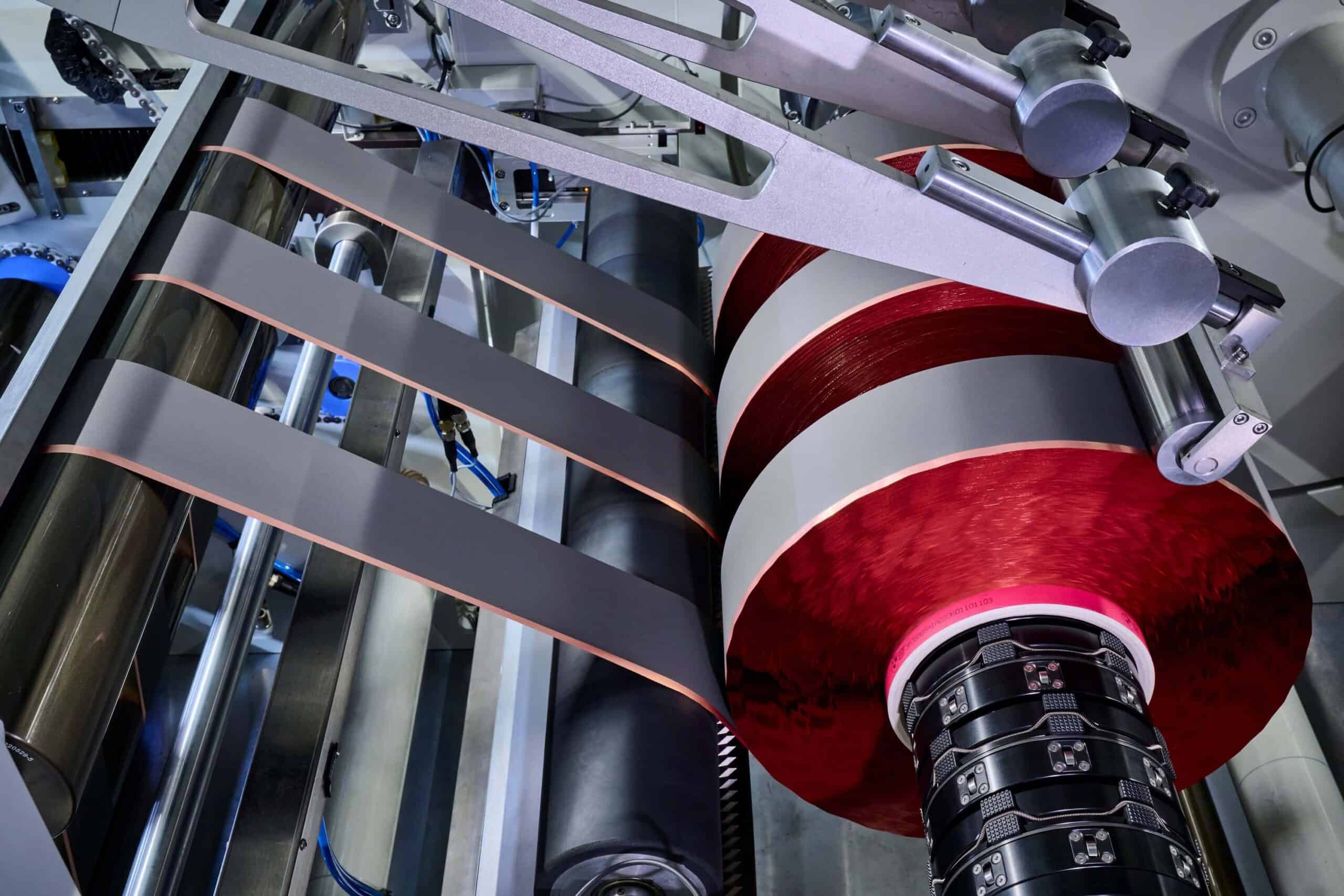

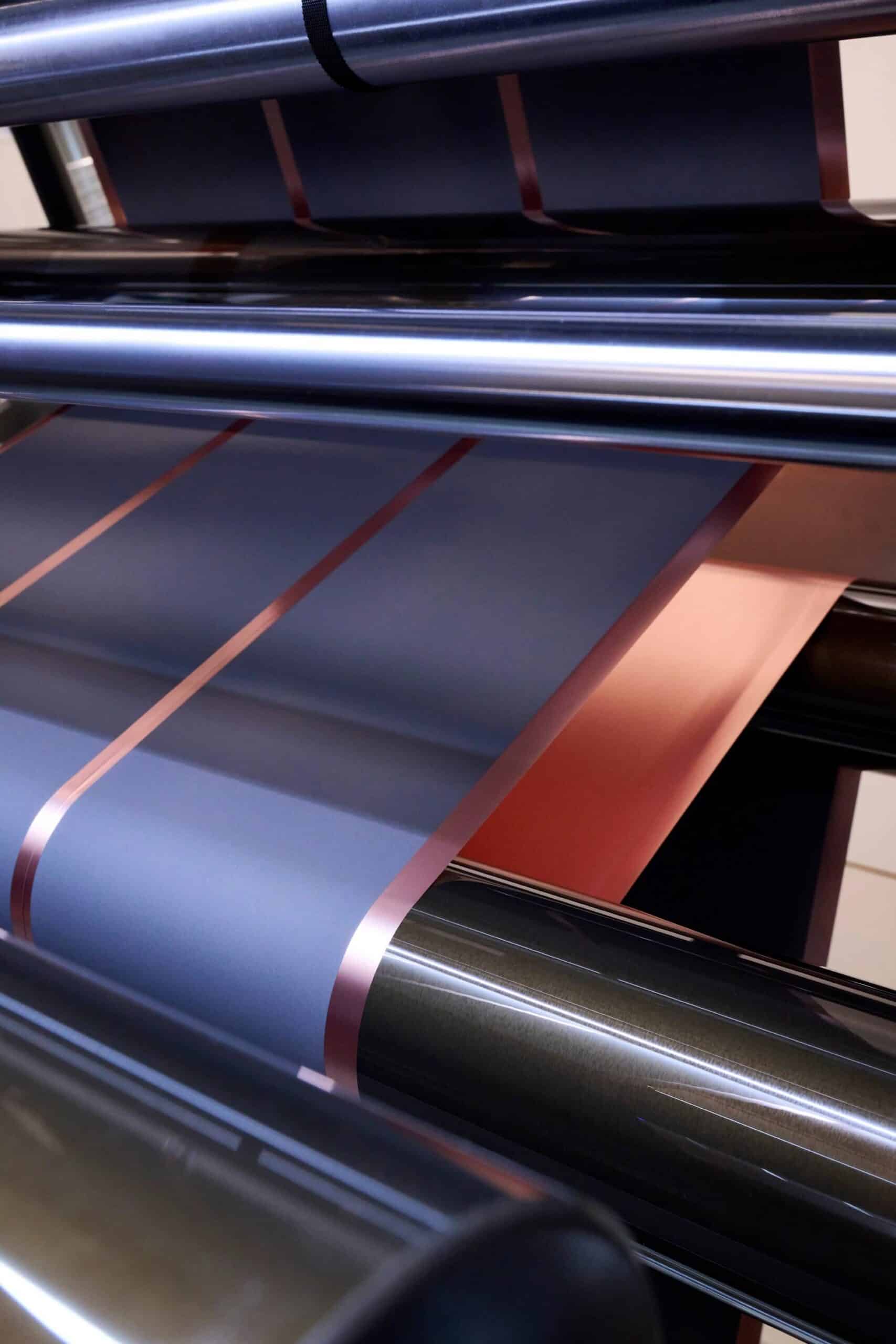

These new cylindrical cells will have a standard diameter of 46 millimeters and two different heights, depending on application: 95 mm for cars and 120 mm for SUVs. Compared to the Gen5 prismatic cells currently being used in BMW EVs, energy density is going to increase by over 20% while the range is estimated to go up by 30% based on the WLTP cycle. In addition, charging speed is projected to get a 30% boost while the emissions generated during the production process will be slashed by 60%.

The nickel content of the Gen6 cells will be higher on the cathode side, while the cobalt content will be reduced. On the anode side, the silicon content will be increased. Another change compared to Gen5 batteries is the use of a higher voltage (800 volts) to enable a higher charging capacity with a current of up to 500 amperes.

The new batteries earmarked for Neue Klasse electric cars are currently being developed at the Battery Cell Competence Centre in Munich. The best products obtained there are then put into series production in Parsdorf. The German luxury marque is already thinking ahead by working on solid-state batteries as well.

A sedan and an SUV in the 3 Series segment will inaugurate the NE platform, with four additional models confirmed to hit the market by 2028. Some of the other models expected include an electric 3 Series Touring and an iX4, with an entry-level i1 believed to be in the pipeline as well. And yes, fully fledged M electric cars are in the making, starting with a zero-emission M3.

Source: BMW