BMW announced in mid-October plans to invest $1.7 billion in its facilities in Spartanburg to prepare for the new wave of electric vehicles. $1 billion will be spent to add at least six electric vehicles to the assembly lines in South Carolina by the end of the decade. The remaining $700 million will go into a new battery assembly facility in Woodruff, SC.

Supporting BMW’s investment will be Japan-based Envision AESC, which this week revealed its intentions to build a new battery plant. Located in Florence, SC, the 1.5-million-square-foot facility powered by 100% net zero carbon energy will require an investment of $810 million and will initially create 1,170 jobs. The annual capacity of the battery cell factory will be up to 30 GWh.

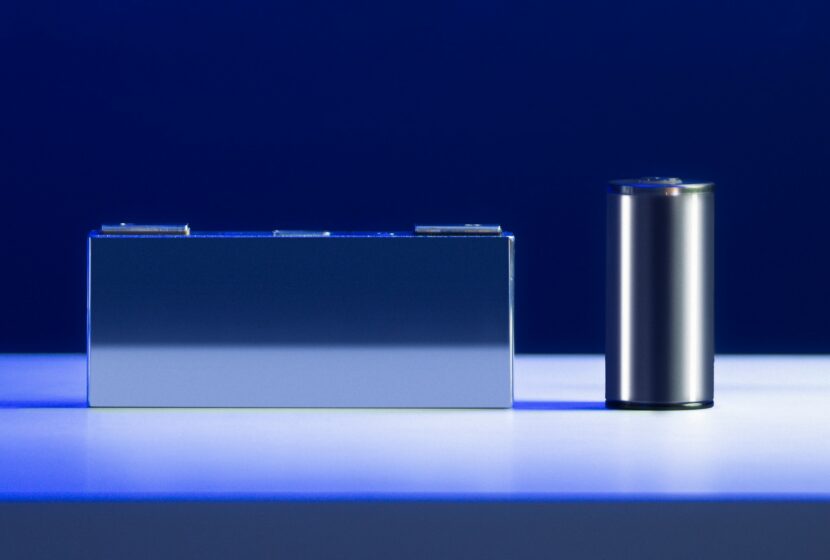

The new batteries will go into BMW’s next-generation EVs, specifically the models riding on the Neue Klasse platform. As previously stated, the Bavarians will be switching from prismatic to round cells, which are touted to bring improvements in all areas. Expect the charging speed to increase by 30% and the range by the same percentage. In addition, round cells will have 20% improved energy density and 50% less manufacturing costs. BMW also says the CO2 generated during the production process will go down by as much as 60%.

The first Neue Klasse-based models are not due until later in 2025 when BMW will inaugurate the Debrecen plant in Hungary. The Munich factory will also build NE-based EVs from 2026, but it looks like Spartanburg is already shaping up to be an important manufacturing hub for next-gen electric cars. It should be mentioned the platform is being engineered to accommodate solid-state batteries as well, albeit these will not be ready for a production car anytime soon.

BMW has yet to reveal which EVs it’ll build in South Carolina, but we’ve heard they’ll all be SUVs. That makes sense considering the Spartanburg plant exclusively builds X models, from the X3 all the way up to the recently launched XM.

Source: Envision AESC