In 2001, the MINI brand launched its brand-new MINI hatch from its Oxford plant and as since sold over 2.5 million MINI vehicles. In its first year open, MINI sold nearly 40,000 cars worldwide, by 2015 the Oxford-based brand sells 340,000 cars worldwide, with 63,000 of those cars being sold in the UK. These are the highest numbers since the brand’s relaunch in 2001. So to honor MINI’s Plant Oxford, we were able to take a visit to it and check out its history.

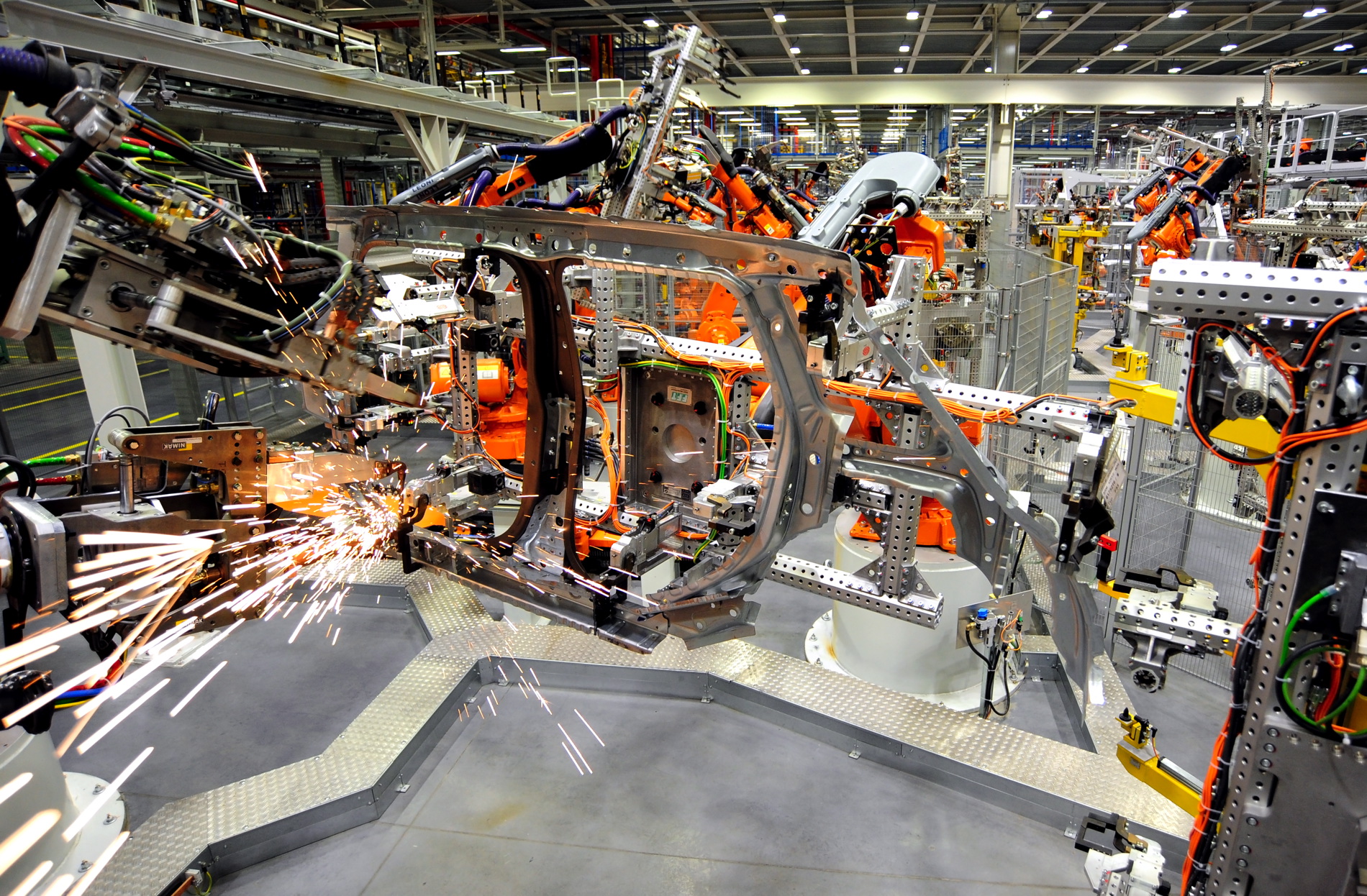

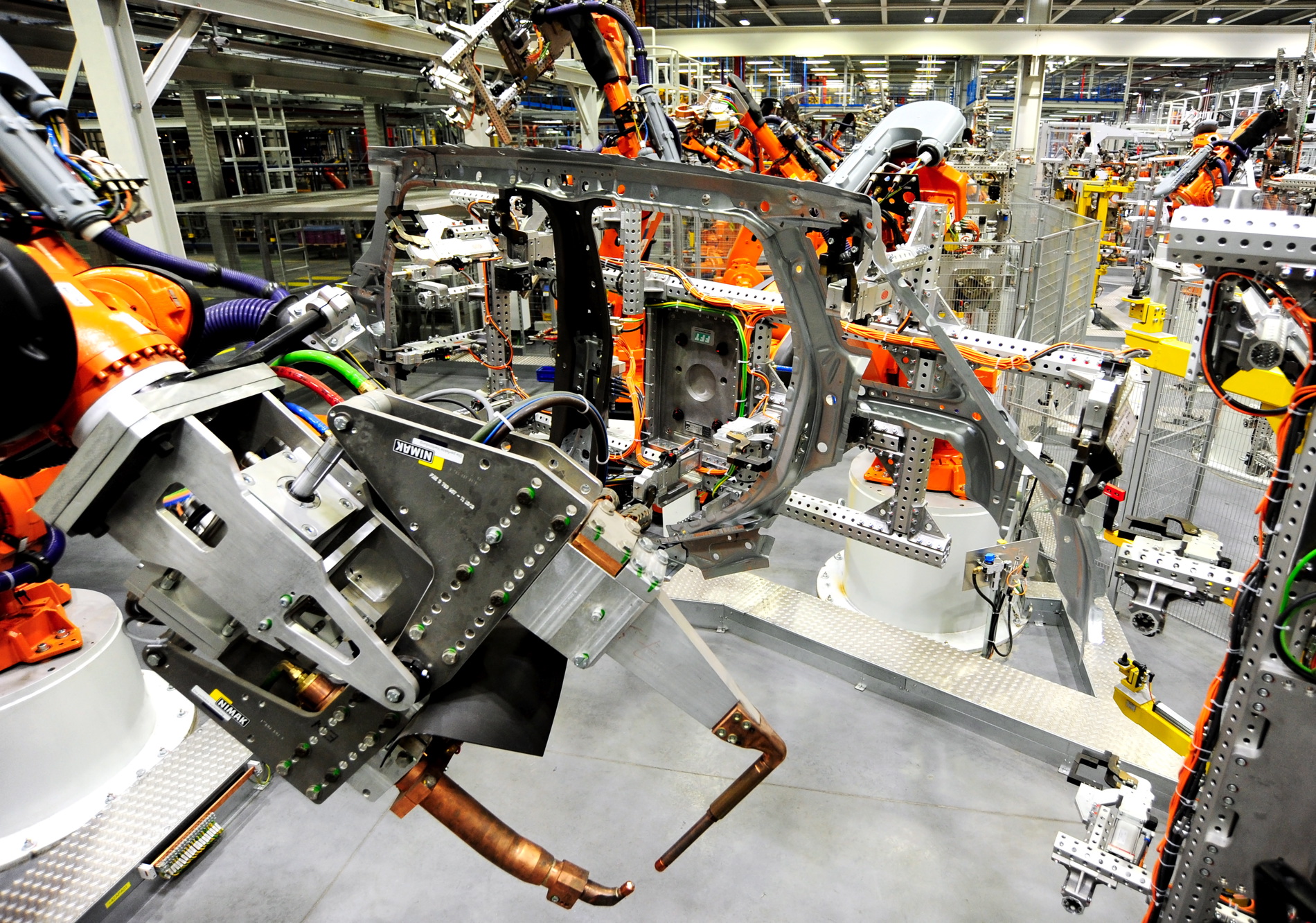

Since 2001, MINI has become an invaluable part of the BMW Group and its plant in Oxford has a lot to do with that. With state-of-the-art-production equipment and an extremely hard working and passionate staff, the Oxford plant produces over 1,000 cars every day.

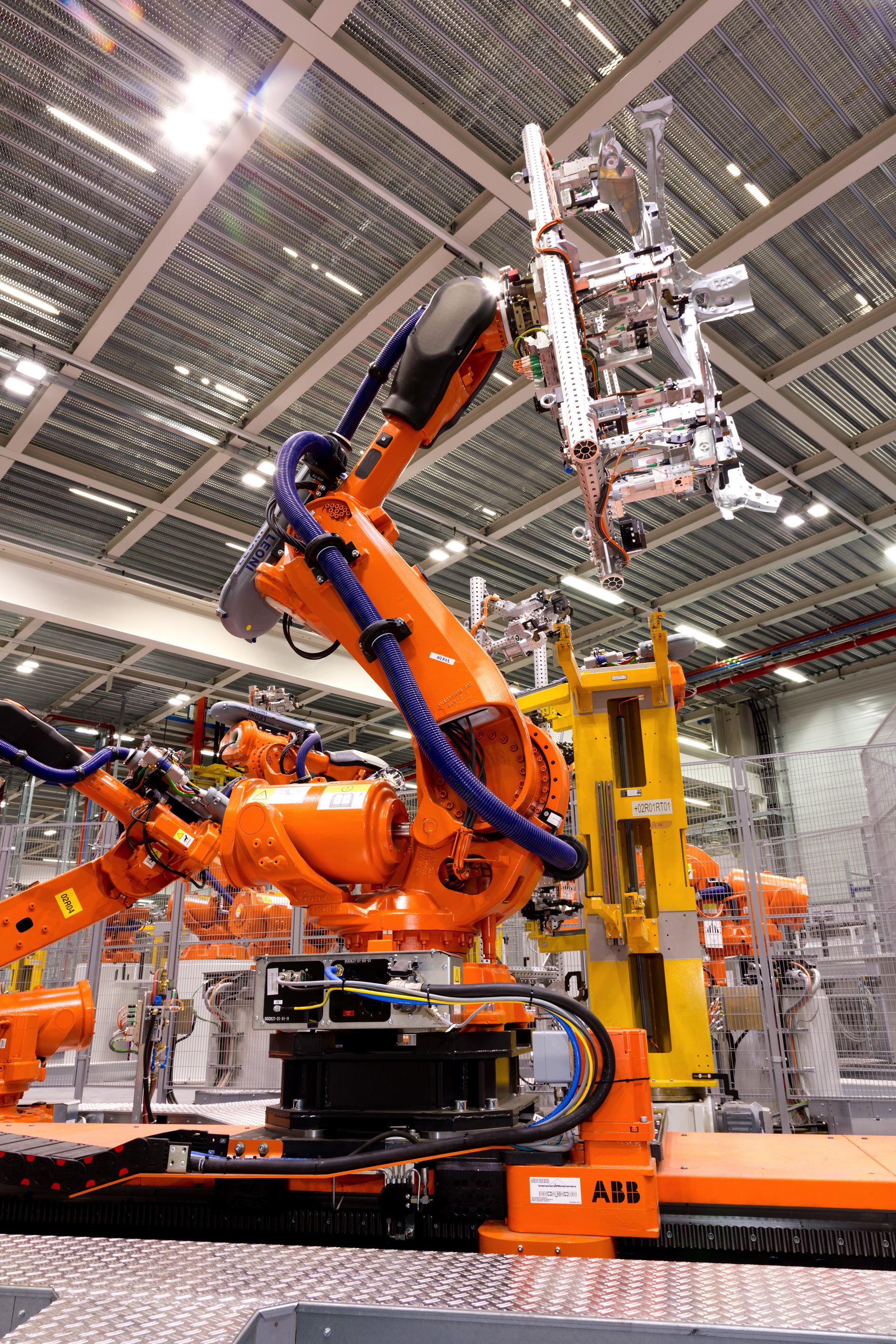

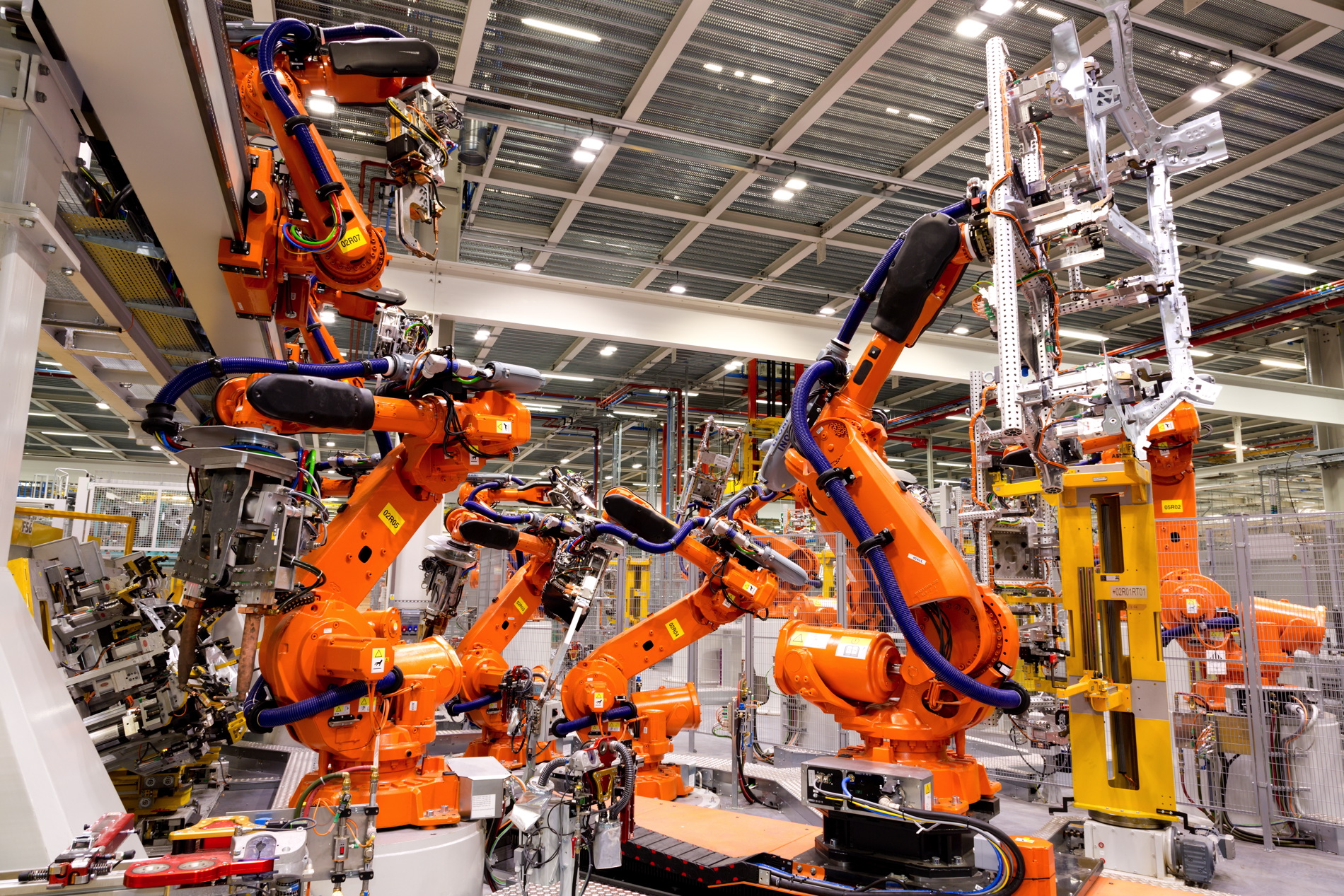

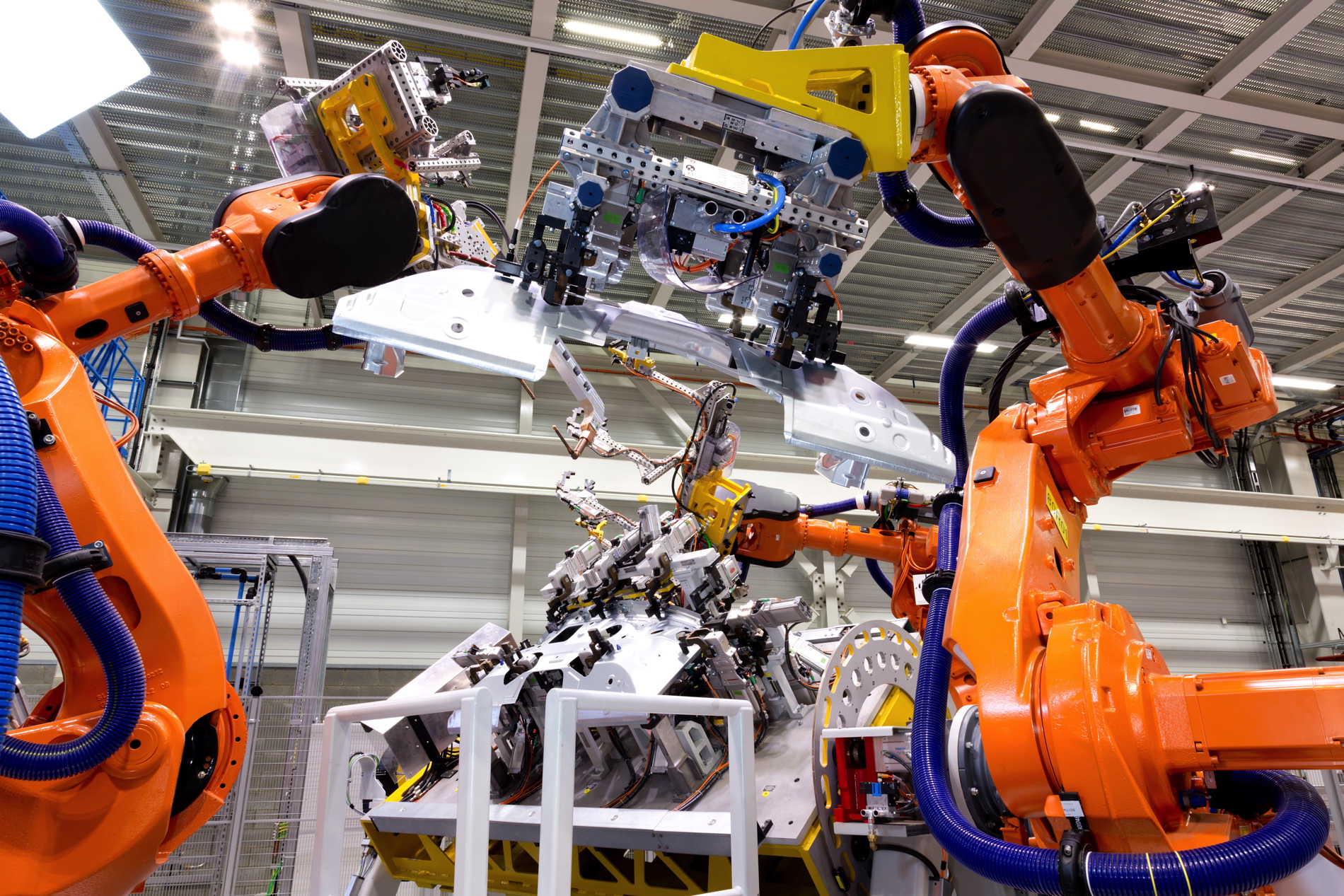

This is done by the 4,500 employees and high-tech equipment that the BMW Group has heavily invested in. Between 2012 and 2015, BMW has put £750 million into the MINI plant in Oxford, bringing the total investment up to £1.75 billion, from the year 2000.

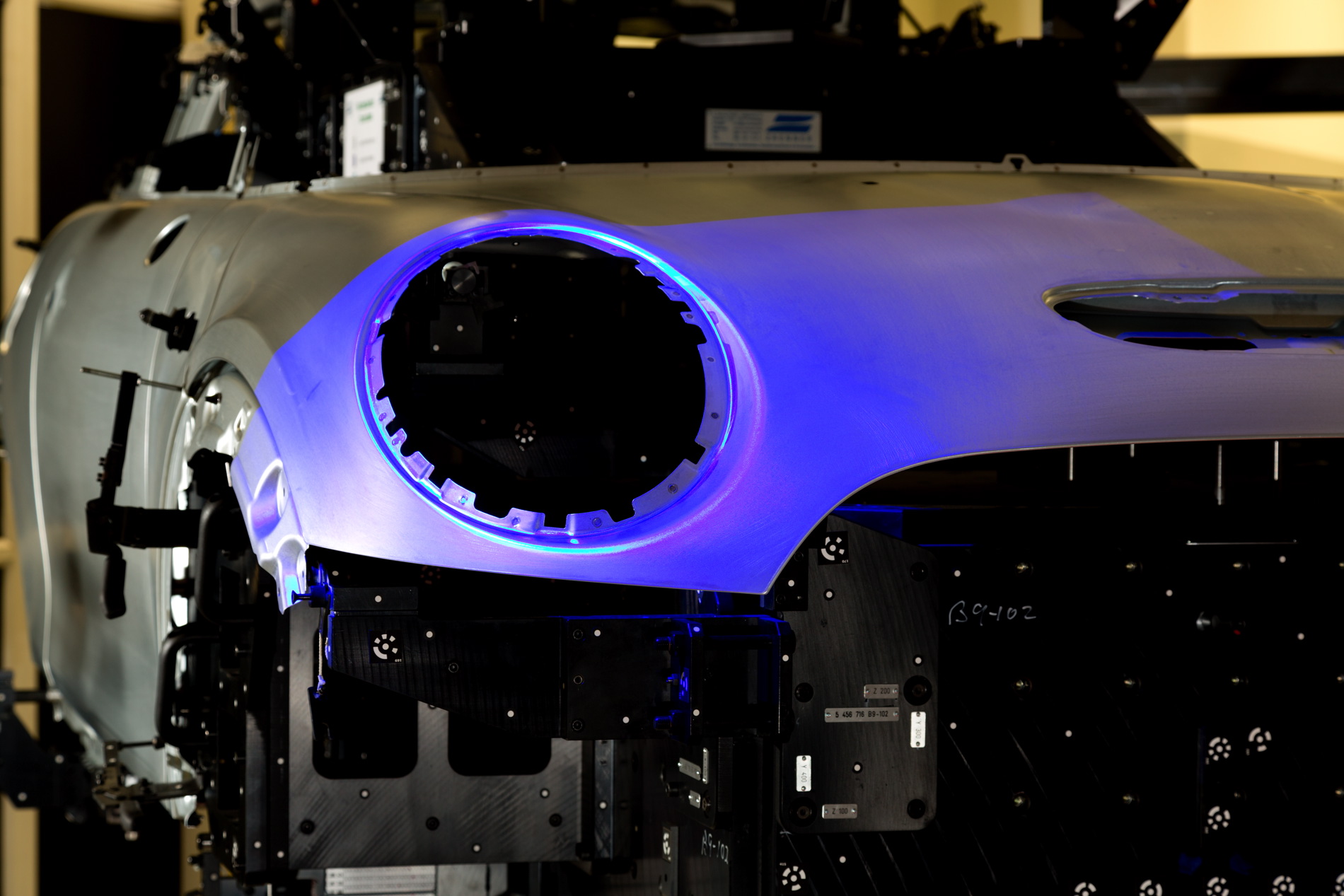

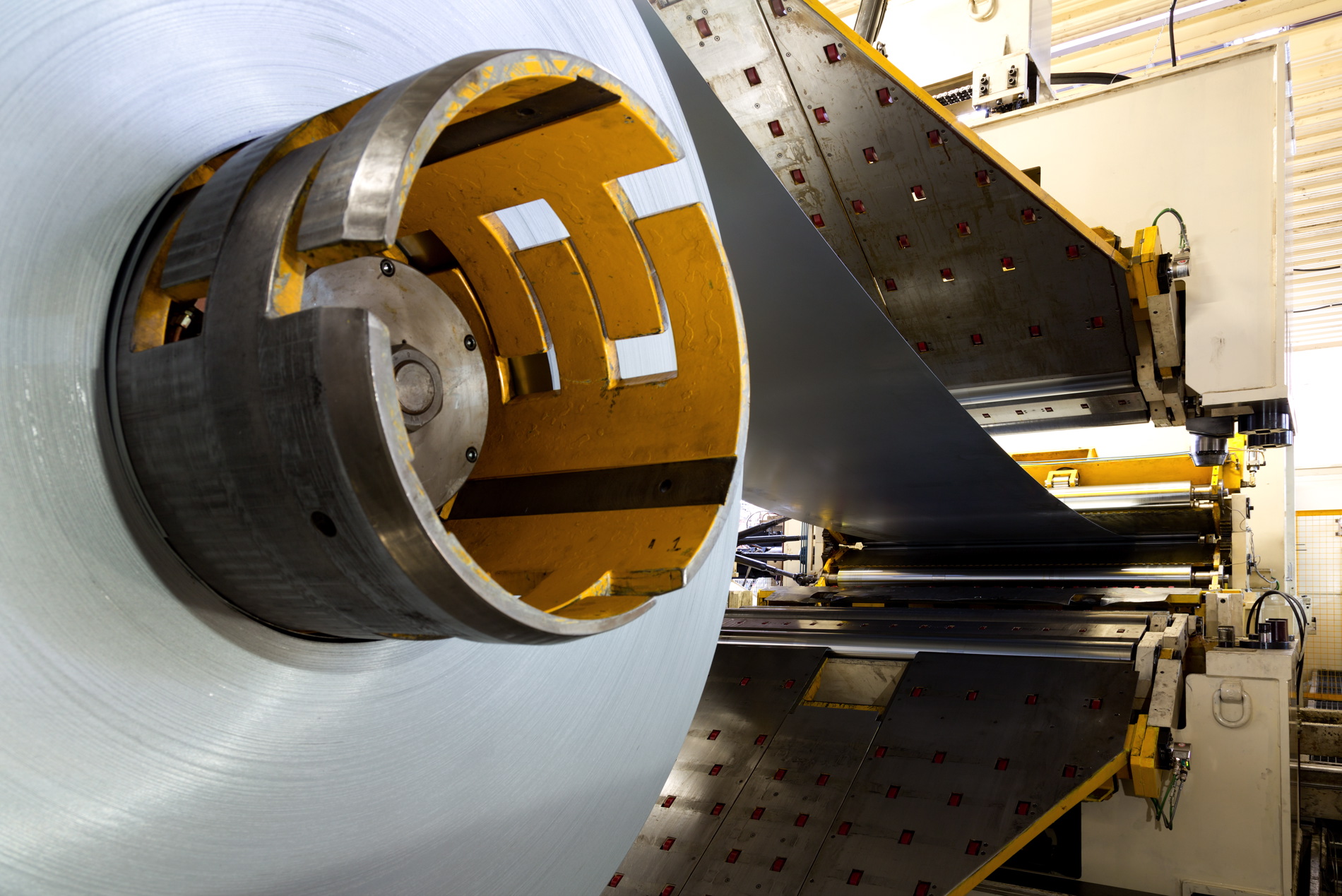

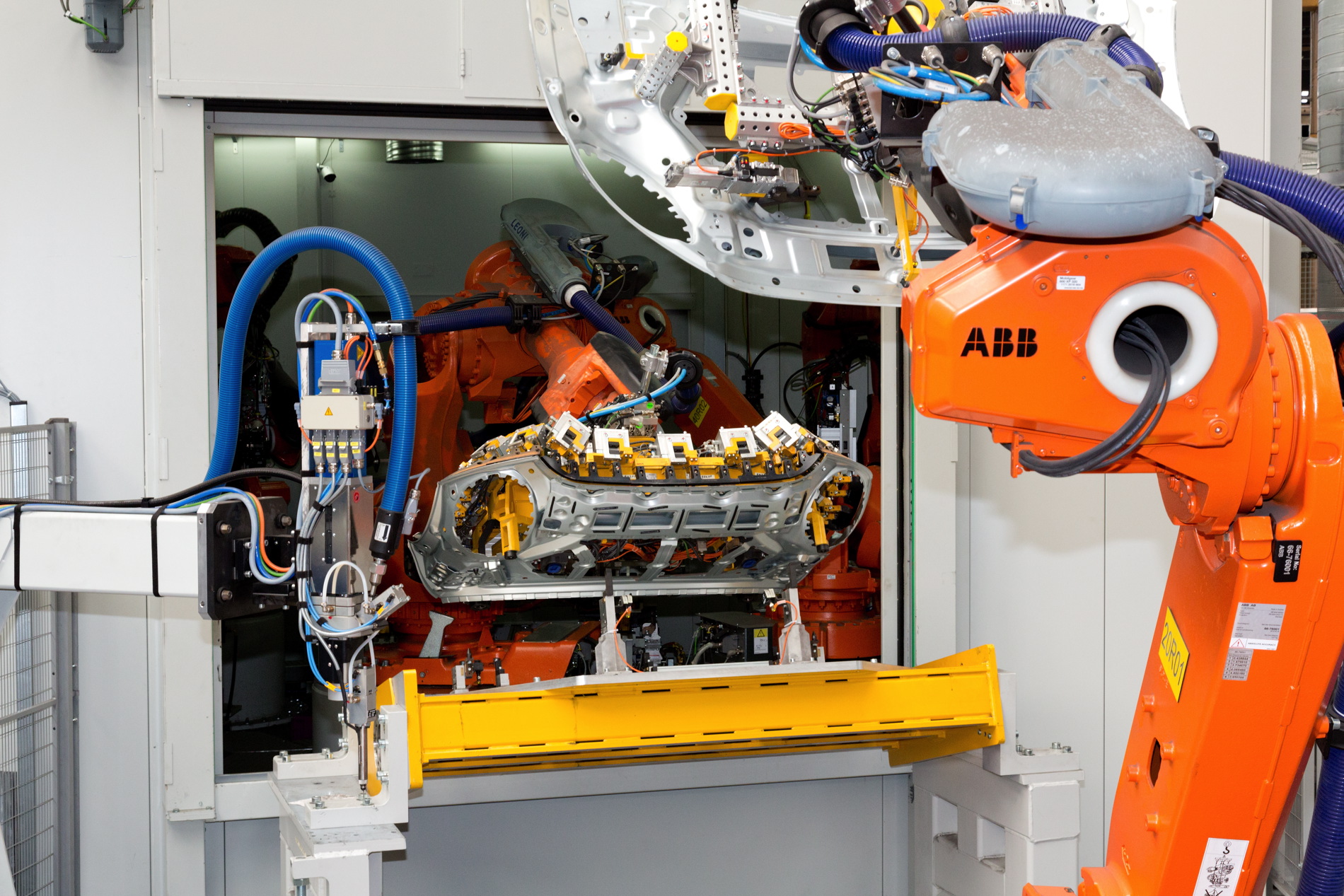

However, the Oxford plant is just one third of the MINI production. A MINI plant in Swindon produces body panels for both MINI and BMW and a plant in Hams Hall produces engines for both MINI and BMW. But it’s the Oxford plant where all of the magic happens. It’s home to to final assembly, where all of the body pieces get welded, screwed and riveted together. Accuracy of every single body is measured by Perceptron cameras which measure to a tolerance equal to half the width of a human hair. There are 500 Perceptron measuring points.

After that, the newly assembled body-in-white is ready for paint. The MINI Oxford plant holds the first paint shop worldwide to use an IPP, integrated paint process. Car bodies are painted in bulk and sorted by colour, not by model and it takes 15 seconds to change colors. MINI employees take such car to rid the freshly painted cars of dust and dirt that they use ostrich feathers, as they’re extremely soft and fine.

Thanks to MINI’s allowance for heavy customization by its customers, MINI vehicles are fitted with transponders during production that hold each car’s DNA. Along the assembly line, the transponder is read a various stations and it communicates with logistics processes to ensure all of the correct customized components are used.

Seeing what MINI was way back when and seeing what it is now is remarkable. MINI is credited to William Richard Morris, who at the age of 15 opened his first bicycle repair shop in his parents’ house in Cowley/Oxford in 1892. The bicycle repair business turned into an automotive repair business in 1901 as the automobile became more popular. After that, WRM Motors Ltd was registered in 1912 to develop automobiles and the Morris Oxford “Bullnose” debuted in 1913. Fast forward to 1952 and the British Motor Corporation formed by acquiring share capital of Morris Motors and Austin Motor Co. In 1959, the Mini is launched and produced at Cowley under the Morris marque.

After many mergers and name changes, the BMC eventually became known as the Rover Group. In 1994, BMW bought the Rover Group and for the next few years developed new Rover models at the plant in Oxford. In 2000, BMW decided to sell off Rover Cars and Land Rover and just keep the Oxford plant where it decided to relaunch the MINI brand and in 2001 the first new MINIs are produced. In 2002, the MINI Cooper S is launched and the rest is history.

MINI has a long, confusing and checkered history, but it now plays a very important role in the BMW Group and both BMW and car enthusiasts everywhere are happy the Bavarian brand brought it back to life. But more importantly than just bringing it back to life, BMW allowed MINI to flourish as the brand it was always meant to be. The MINI character and charm is still very much alive in all of its new cars and much of that has to do with the fact that they’re still built in Oxford, England.