Recently, Matt Petrany of Jalopnik sat down with Adrian Van Hooydonk, BMW’s Head of Design, to talk about carbon fiber construction.

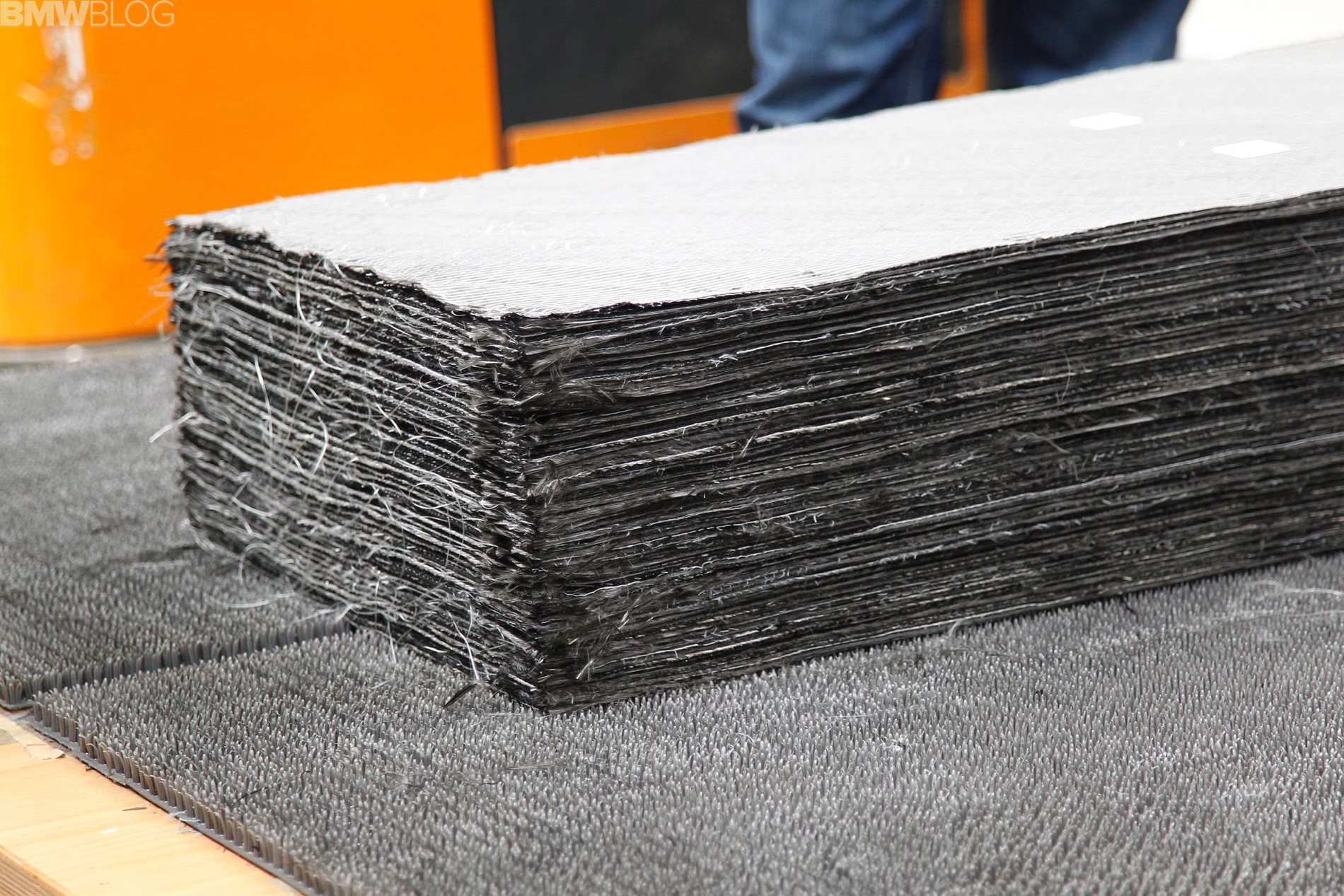

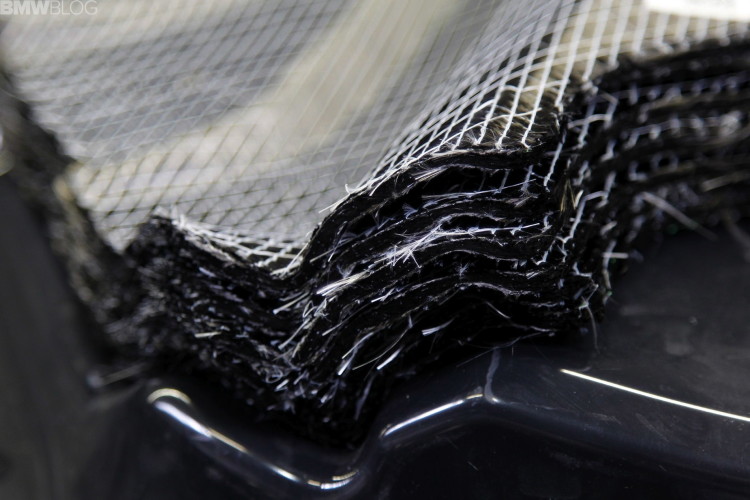

When BMW created the i3 and i8, it developed a new kind of carbon fiber reinforced plastic and a new process of developing it. This helped create a lightweight platform in which to build the aforementioned vehicles. The light weight of the CFRP allows BMW to make the i3 and i8 more economical and have better performance.

Obviously, BMW wants to move forward with CFRP construction in every BMW vehicle eventually. Apparently, BMW wants to start with the 3 Series. It will just take a while to get there.

At the moment, a CFRP chassis is far cheaper and faster to make than a traditional carbon fiber chassis. However, it’s still far more expensive and takes far longer to make than a conventional steel or aluminum chassis.

The benefits of the CFRP chassis would be extraordinary to the 3 Series, or any car for that matter. It would give the 3er a significant advantage over the competition in terms of performance, safety and fuel economy. BMWs have gotten a bit heavy in recent years, which is par for the course in the auto industry nowadays, so a new, CFRP chassis would be an incredible upgrade.

Driving the i3 is an extraordinary experience and the CFRP chassis has a lot to do with it. It’s also what makes the i3 so innovative.This kind of chassis would be a game changer in regular gasoline or diesel powered vehicles. I hope BMW can hurry along the development process for CFRP and can implement it into standard cars soon. The idea of a CFRP M3 gets me giddy.