Altairenlighten.com sat down for an interview with Dr. Joerg Pohlman, Managing Director of SGL Automotive Carbon Fibers to discuss carbon fiber materials and recycling, Composite Crash Performance and Lightweighting Electric Vehicles.

BMW Group and the SGL Group operate a joint venture. The SGL Group holds 51% and the BMW Group 49 % of shares in the joint company, SGL Automotive Carbon Fibers. The two partners have built a new state-of-the-art carbon fiber manufacturing plant together in Moses Lake in Washington State in the U.S. The new plant plays an important part in the two companies’ strategy to automate the production of ultra-light carbon fiber reinforced plastics (CFRPs) for use in future vehicle concepts.

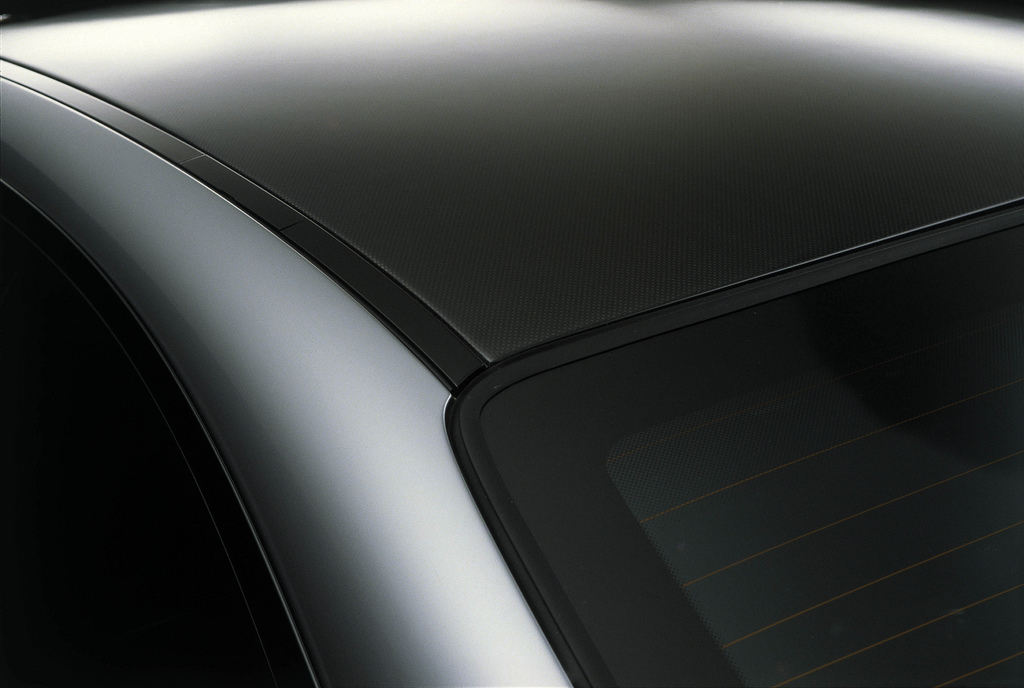

The carbon fibers produced in Moses Lake are being processed at facilities in Wackersdorf and Landshut. Wackersdorf delivers textile fabrics made from carbon fibers, which are then being processed at the BMW plant in Landshut to make lightweight CFRP body components for the BMW i3 and BMW i8. Both vehicles will be assembled at the BMW plant in Leipzig. The BMW i3, the BMW Group’s first series-produced electric vehicle, will be released on the market in 2013, followed by the BMW i8 sports car shortly afterwards.

Here is the video interview: