Engine

At the heart of this car is the stroker motor BMW built for the M3 GTS. It’s got that extra dollop of torque to pull you out of the corners. The base M3 motor is a real gem and the 4.4L version is just that extra bit better (and more fun in the process).

Increasing the length of travel of the piston in it’s cylinder, and subsequently, the further offset of the connecting rod journal from the center of the crank – which increases the lever action of the connecting rod – adds torque to a motor. It’s a time honored way of making additional power from an existing configuration. It’s a good place to start when building a special vehicle, a German Hot Rod if you will.

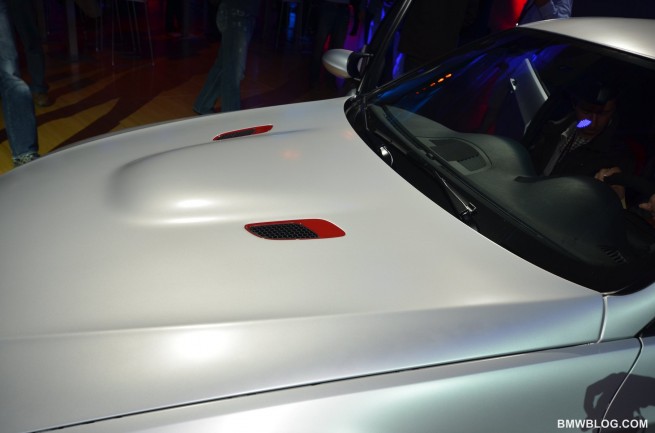

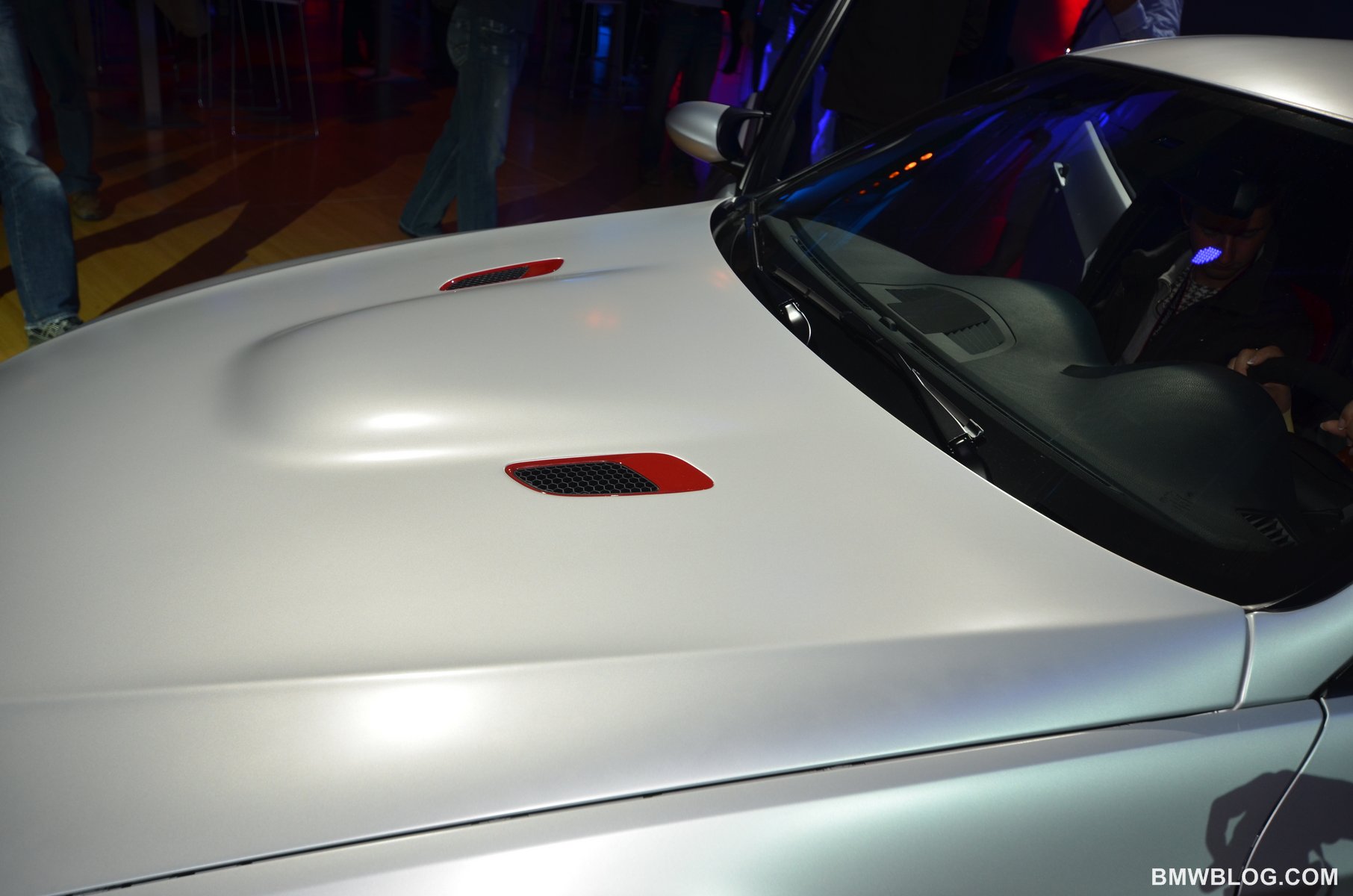

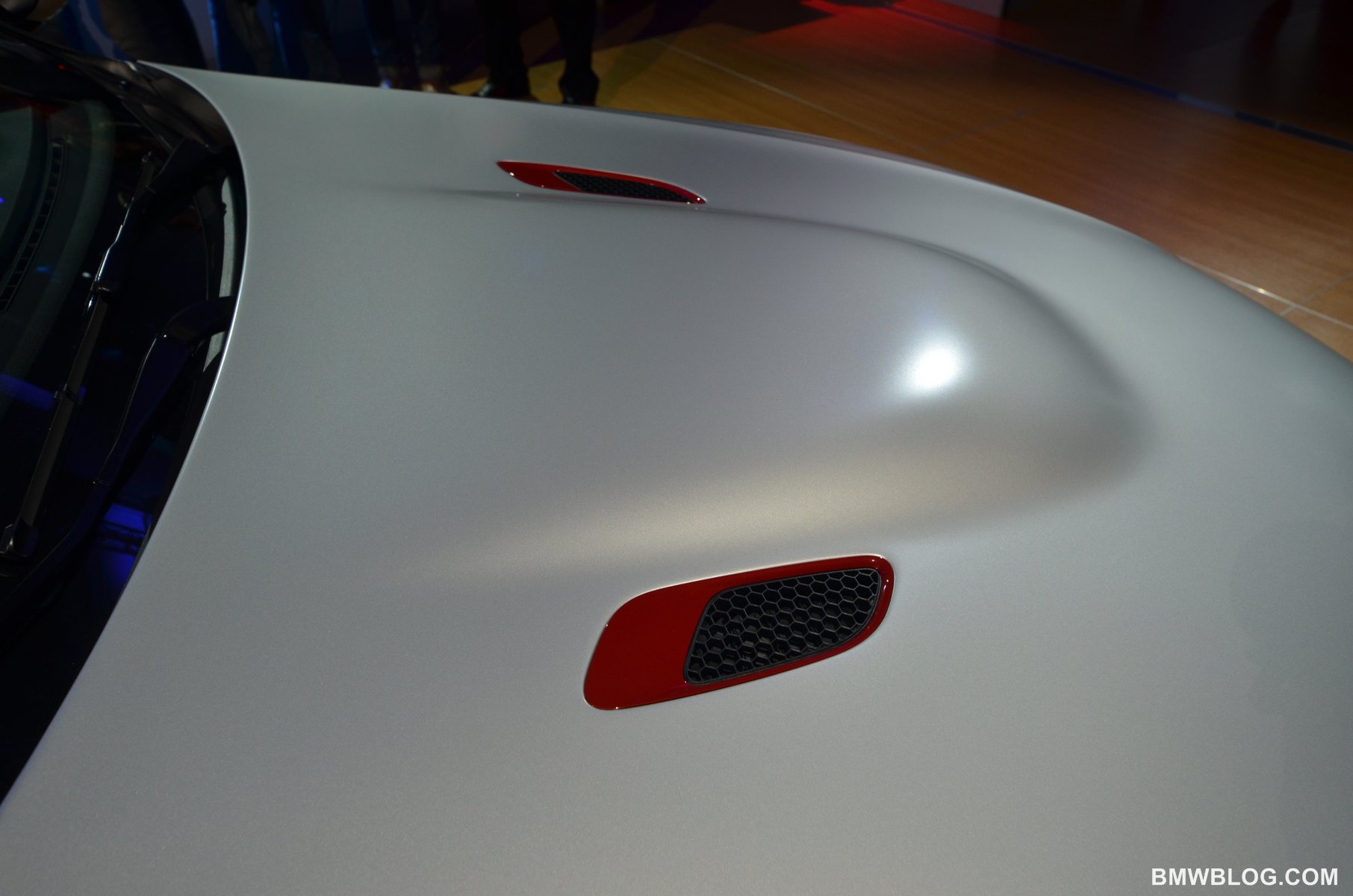

From that starting point why not hot rod a four door saloon? A baby M5? Well not quite, but certainly something just that much more special than the already fantastic M3 sedan. So how do you shed pounds? BMW has done it by using some of the technology they have showed off in Innovation Days. First up, the carbon fiber honeycomb hood.

What’s really neat about this is the method and materials used to manufacture the hood. They use cuttings (scraps) from the manufacturing process of larger panels to build these panels. From the press release, “In a new development, the production process introduced for this purpose enables the cuttings left behind in the construction of the body to be reprocessed. The basic material (made up of carbon fibre thread) can now be woven into CFRP mats of any size before being impregnated with synthetic resin and hardened in a similar way to the material used in the body of the BMW i3 and BMW i8.” Sustainability with a vengeance (and a 4.4L V8)!

Couple that with a pair of lightweight front seats (and from the pictures some seriously scalloped out rear seats) and the weight savings comes to about 150 lbs. These seats (or a close relative of them) were shown at Innovation Day this year also.

So you tweak the motor for more power, tweak the chassis to reduce weight and pretty soon you’ve got a four door car that’ll flat fly. But it’s the seats that’ll keep this car from being imported to the US. They do not have provision for airbags and that’s a non-starter in the US. So none of the 67 M3 CRT sedans will make it here.

Chassis (Suspension and Brakes)

Peeking out from behind the lovely M Y-spoke wheels are a set of compound construction rotors and fixed six-pot calipers also seen at Innovation Days. The rear sub-frame is rigidly attached to the uni-body, so handling will trump comfort in this car (and that’s the way you want it). The shock absorbers are adjustable for both rebound and compression (as they should be in a serious handling machine). Couple all of this with a 51.6/48.4 weight balance and M tuned DSC and it’ll be the E-ticket ride for your kids’ visits to the orthodontist.

The Unfinished Finish

As the resident curmudgeon of BMWBLOG, and applying my jaundiced eye (with regards and apology to Leon Mandel for using his trademark), I tend to snicker at the fawning over matte finishes. They are a pain in the a$$ to care for, and if you know anything about hot rods (which is where matte – read flat – finishes got their start) you’d know that they represent an unfinished state. Hot rodders left their cars in primer (originally) not because it was cool, or should I say KEWL, but because they couldn’t afford to finish the paint process. Hot rods were always ‘works-in-progress’ and the ‘rat rod’ phenomenon tends to honor that transitional stage in a hot rod’s life from primer to the full-on ultra-glossy high depth flaming candy apple red paint job by ‘freezing’ their cars in the unfinished state.

So, from my perspective, the ‘frozen’ paint is just that – a frozen intermediate state between being built and finished. Give me a nice high gloss machine tool grayish blue and I’ll be a happy camper, but leave the unfinished frozen finishes for others.

Conclusion

It’s neat that BMW is thinking about cars like this. Coming on the heels of the F10 M5 launch the M3 CRT sedan certainly is an nice addition to the custom portfolio and a neat way of ushering in a set of innovations shown in April into production in June. It’s too bad we won’t see any of these in the United States.