Latest Stories

BMW iX3 vs New G45 X3 – What Are The Differences

BMW’s naming conventions have placed them in an interesting pickle. While the fourth generation of the BMW X3 is on the way, it shares nothing with the similarly named BMW iX3. These are both further…

2025 BMW M5 Sedan Colors Revealed In Leaked Order Guide

Although BMW has been focusing on the M5 Touring G99 during the teaser campaign, it’s the sedan we’ll see first. Debuting in the coming months, the G90 is making the headlines via China. The order…

BMW X7 With 24-Inch HRE Wheels Doesn’t Go Unnoticed

BMW limits the maximum wheel size for the X7 to 23 inches. Should you want an even bigger set, you can always count on the aftermarket scene. This facelifted version of the biggest SUV the…

2025 BMW M5 Wagon Caught Testing In The US

As if we needed more proof the M5 Touring is finally coming to America, the G99 has been spotted on US soil. BMW is putting the finishing touches on the eagerly awaited super wagon ahead…

2025 BMW i3 Electric Sedan Facelift Spotted

MINI Aceman: One More Teaser Before the Unveil

Enthusiasts of MINI will be excited about the upcoming Beijing International Automotive Exhibition, taking place from April 25 to May 4. At this event, held at the China International Exhibition Center in Beijing, MINI will…

Driving the Armored and $530,000 BMW i7 xDrive60 Protection

Armored vehicles are a global trend, and electric cars are prevalent in many industrial nations. BMW is the first manufacturer to combine both armored protection and electric propulsion in the 7 Series. And hardly anyone…

2025 ALPINA B3 Spied Hiding Another Facelift

It’s been less than two years since ALPINA unveiled the revised B3, but another update is already on the way. Spy shots taken on a rainy day show the sports sedan with camouflaged bumpers concealing…

BMW Museum Revamps Its Lobby With Sleek New Look

The BMW Museum gets a new look for 2024. Well, the entrance area that is. The German luxury brand doesn’t say how much money it invested in giving the lobby area a fresh design. While…

BMW Spending €200 Million At Plant Landshut To Make Neue Klasse Parts

BMW is massively investing at multiple sites across the world to get everything ready for the Neue Klasse’s arrival. The iX3 will get the ball rolling in 2025, followed a year later by the i3…

2025 Mazda CX-80 Debuts As BMW X5 Competitor

The battle in the upper echelon of SUVs is intensifying with the arrival of Mazda’s first-ever CX-80. Essentially a larger, three-row version of the CX-60, the newcomer has more than a few things in common…

Videos

See allTest Drives

Driving the Armored and $530,000 BMW i7 xDrive60 Protection

Armored vehicles are a global trend, and electric cars are prevalent in many industrial nations. BMW is the first manufacturer to combine both armored protection and electric propulsion in the 7 Series. And hardly anyone…

Review: 2024 BMW 750e xDrive – Is the Best 7 Series a Plug-In Hybrid?

BMW has given the latest 7 Series, the G70, a very bold and controversial face, and the car is also taller than any 7 Series that has gone before it because it needed to fit…

First Drive: New 2025 BMW X3 M50

BMW is putting the final touches on its new X3 family, which will roll out this summer. Ahead of the introduction, set for mid-June, I traveled to Miramas, France, to sample two prototypes. The first…

Review: 2024 BMW M340i xDrive – Jack of All Trades

There are a few ways you can evaluate greatness. One way is to showcase the best attributes of something within a given design. Another way is to examine how any downsides were mitigated to achieve…

Editor's Pick

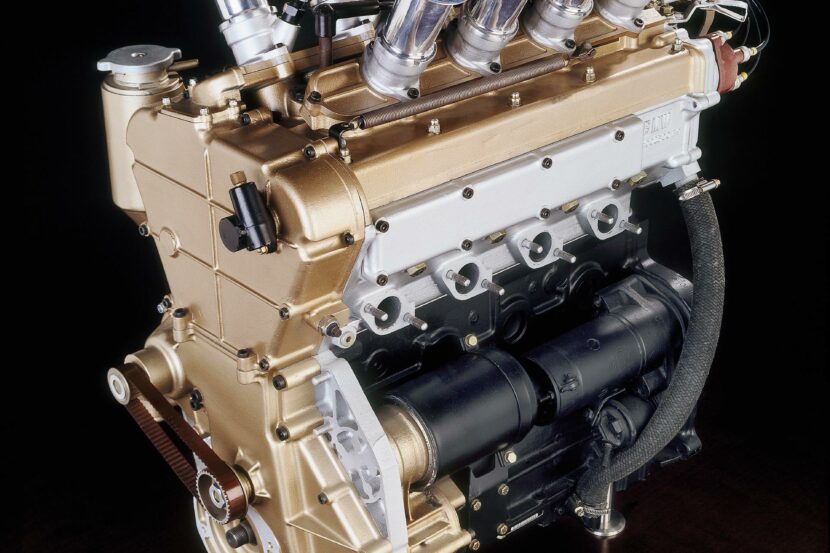

The M10 BMW Engine—BMW’s Longest-Running Power Plant

The M10 BMW engine—BMW’s longest-running power plant—made its debut at the 1961 Frankfurt Motor Show alongside the all-new BMW 1500 ‘Neue Klasse’ (New Class) sedan. The 1500 was a new and very modern car with…

Driving Through History: The BMW E38 7 Series at Thirty

It was someone at BMW who justified the all-new E38 7 Series – launched thirty years ago this year – by suggesting that customers in that class would buy a car for a second time,…

2024 BMW Z4 M40i Six-Speed: First Impressions

At the beginning of this month, we journeyed to the 2024 Amelia Island Concours d’Elegance, not just to marvel at classic cars but also to take the new 2024 BMW Z4 M40i for a spin….

Top 10 BMW M Colors Named After Racetracks

Laguna Seca Blue. Dakar Yellow. Isle of Man Green. No matter where you look in BMW M’s history, race-inspired color names tend to pop up. It makes sense that these high-performing cars (and SUVs) would…

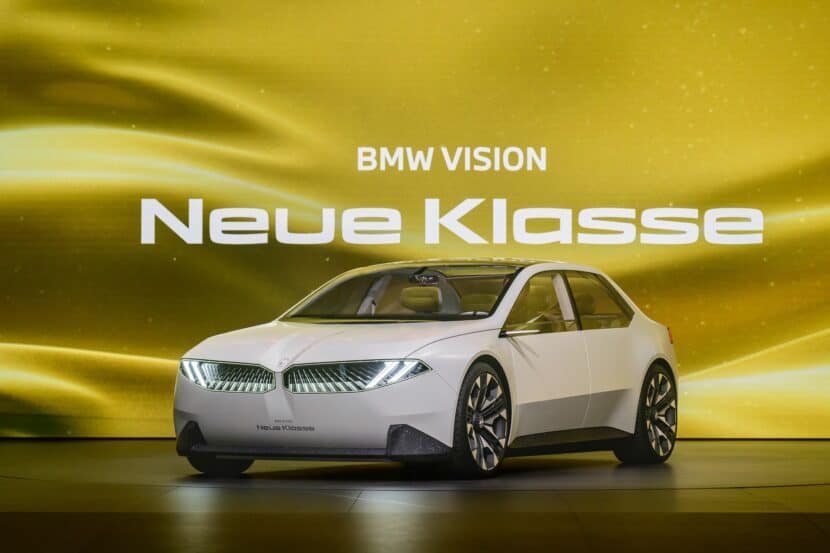

2025 BMW Neue Klasse: Everything We Know So Far

The Neue Klasse is BMW’s designation for a series of all-electric models set to debut in the next half of this decade. The name, reminiscent of the original Neue Klasse sedans produced from 1962 until…